Aluminum fabrication service – Alusite

Alusite provides one-stop full service (OEM) for new product development starting from conceptual design and prototyping to mass production. We have experienced engineers who will help you through this process in order to develop and analyze your designs for manufacturing and aluminum fabrication.

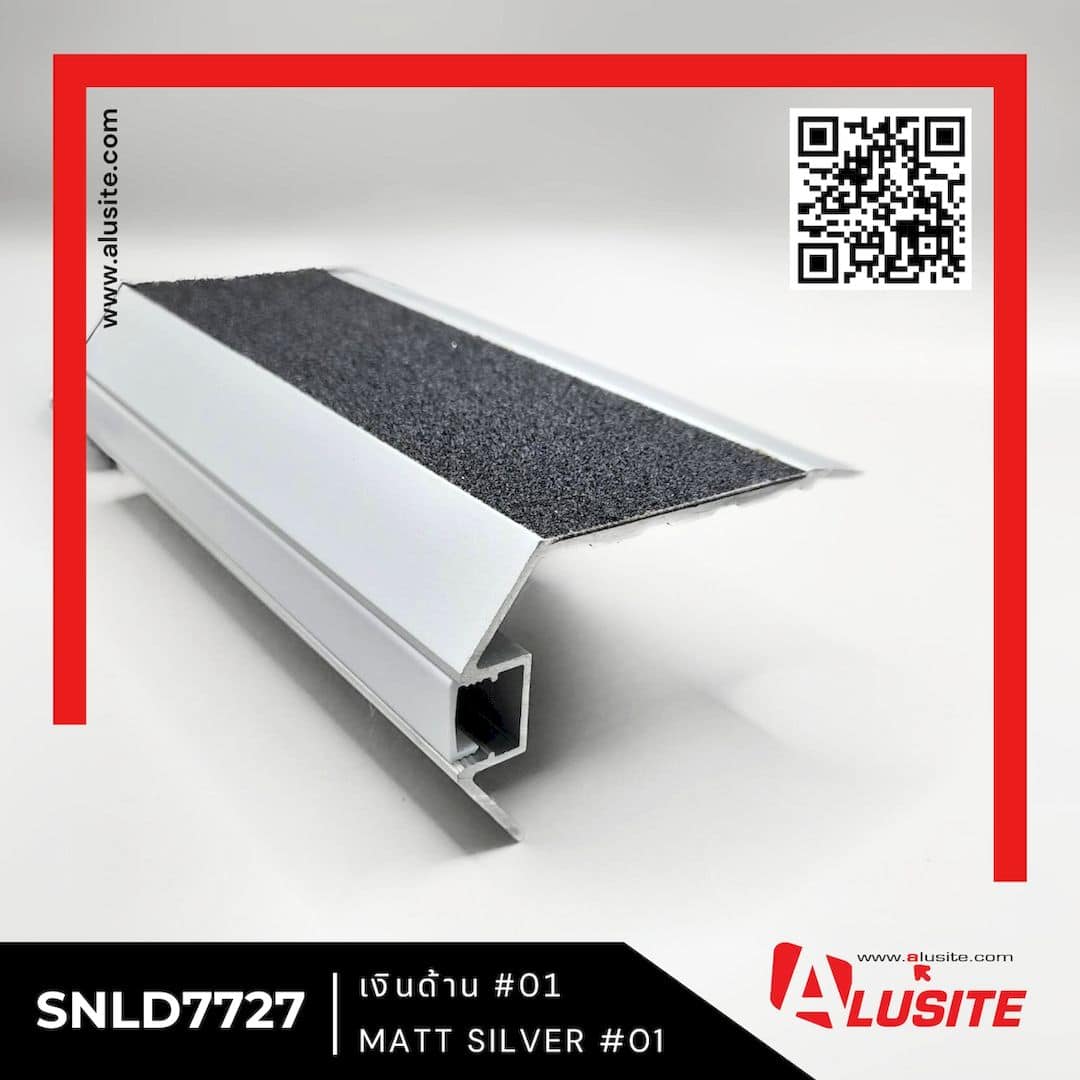

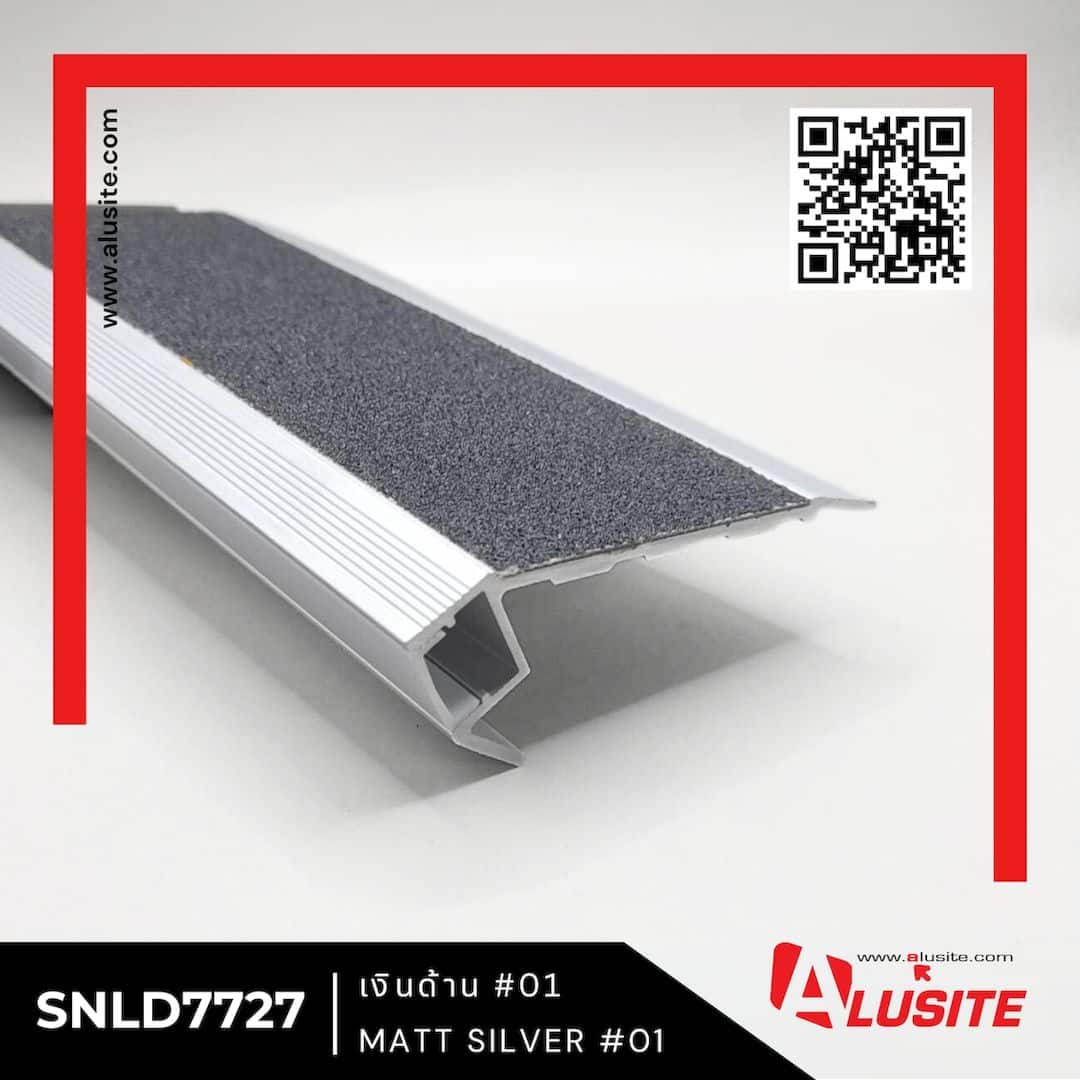

Aluminum fabrication services in Alusite have one-stop full-service starting from design development & prototyping then the next step is precision cutting. We utilized high-speed precision cutting on medium and thin profiles to ensure that our aluminum has ensured smooth edges and high tolerance cutting.

Forming and bending are also aluminum fabrication services. We are experienced in alloy selections and heat treatments with our extensive in-house knowledge. We offer a full range of aluminium bending and forming services.

Aluminium stamping and punching with our in-house mold design and manufacturing service, we provide customized precision aluminium stamping and accommodate other specialized contract manufacturing in aluminum fabrication.

Aluminium CNC (Computer Numerical Control) machining and 3D printing are also our aluminum fabrication services. We specialize in machining, and aluminium parts and components. Our capabilities range from milling, boring, turning, drilling, tapping, profiling, and pocketing.

- CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools.

- Milling is the process of machining using a rotary cutter to remove material by advancing a cutter into aluminium.

- Boring is the process of enlarging a hole that has already been drilled in aluminium.

- Turing is a material removal process, which is used to create rotational parts by cutting away unwanted aluminium.

- Drilling is the process of cutting holes in aluminium using a rotating cutting tool.

- Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole.

- Pocketing is the process that happens when you want to remove all aluminum with a closed boundary down to a set depth.

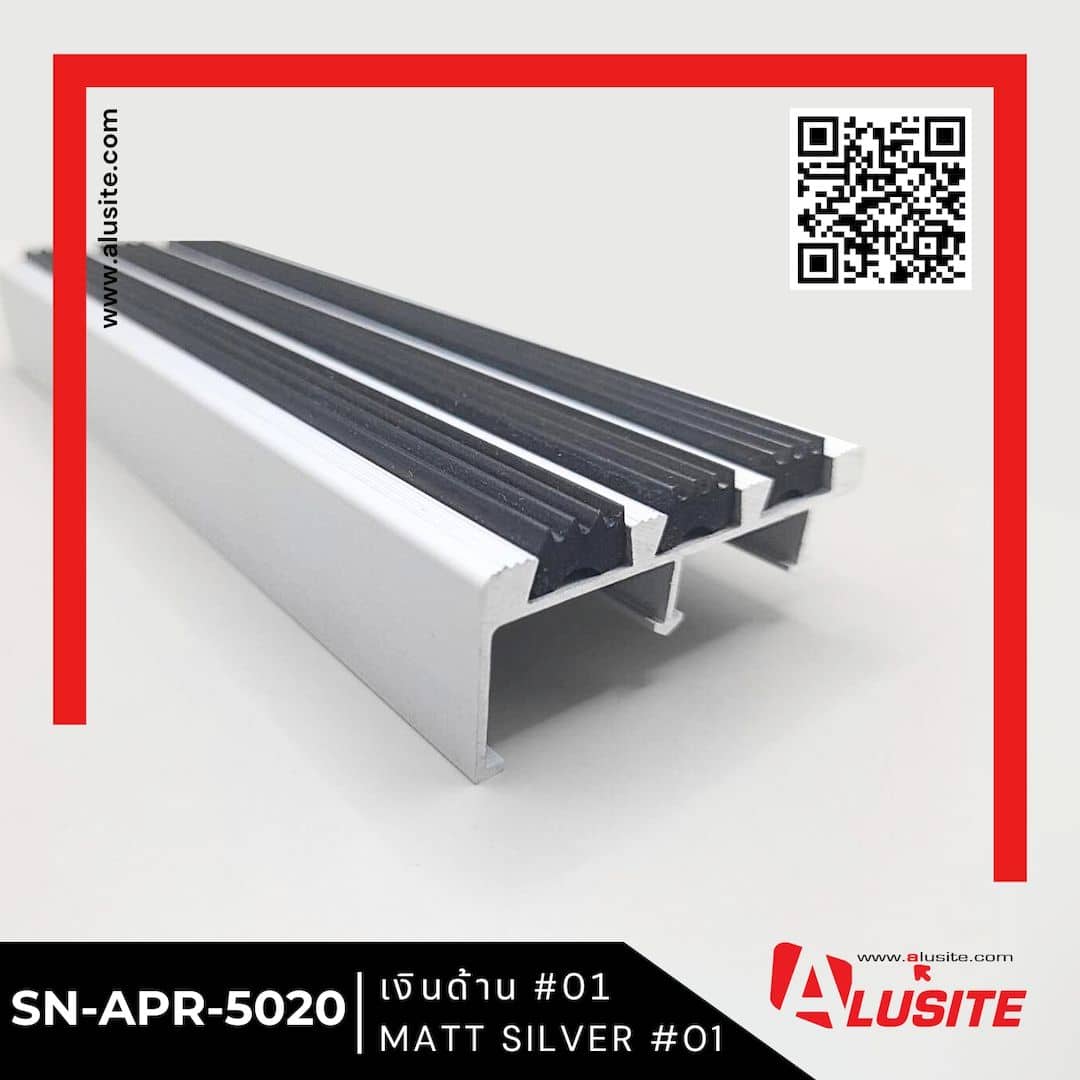

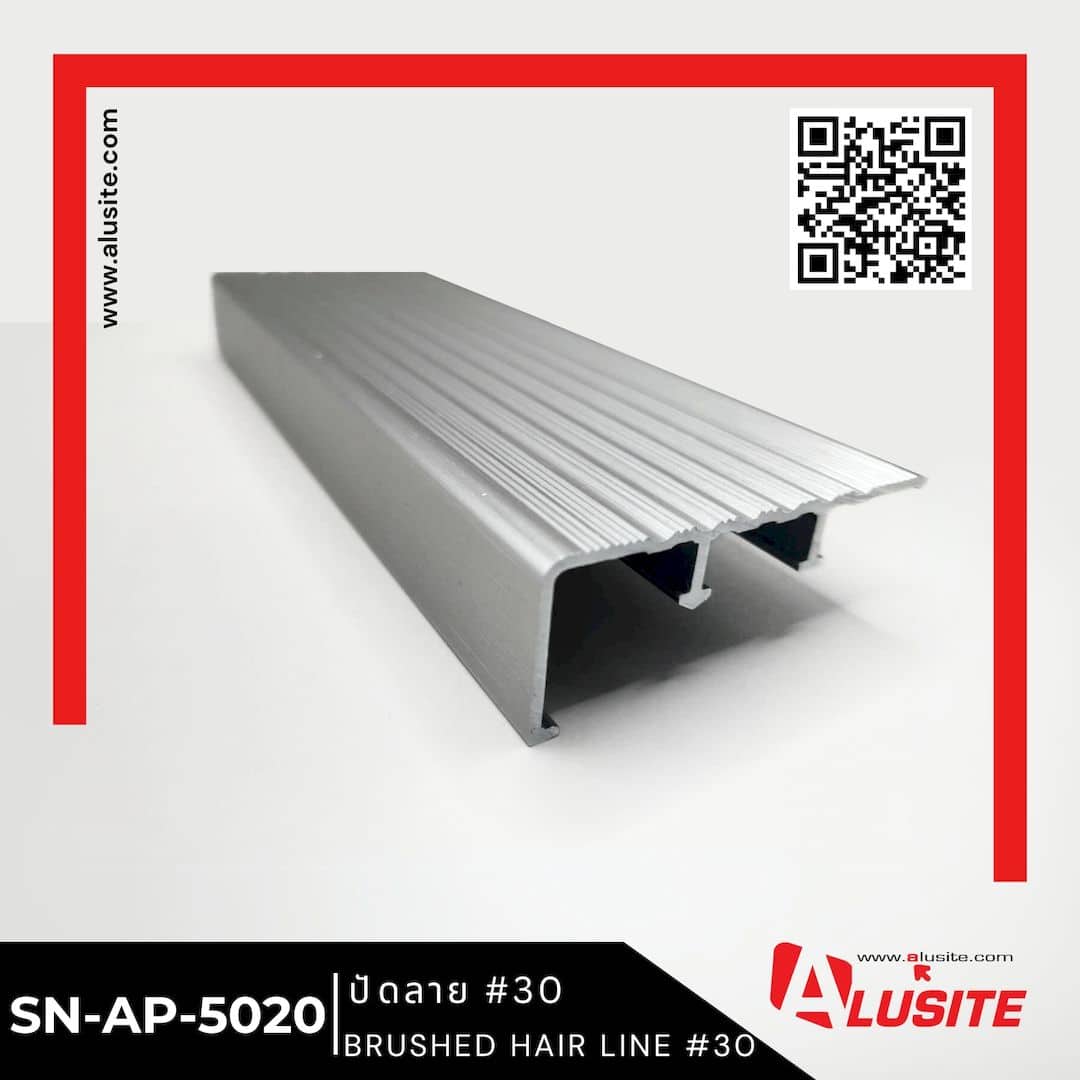

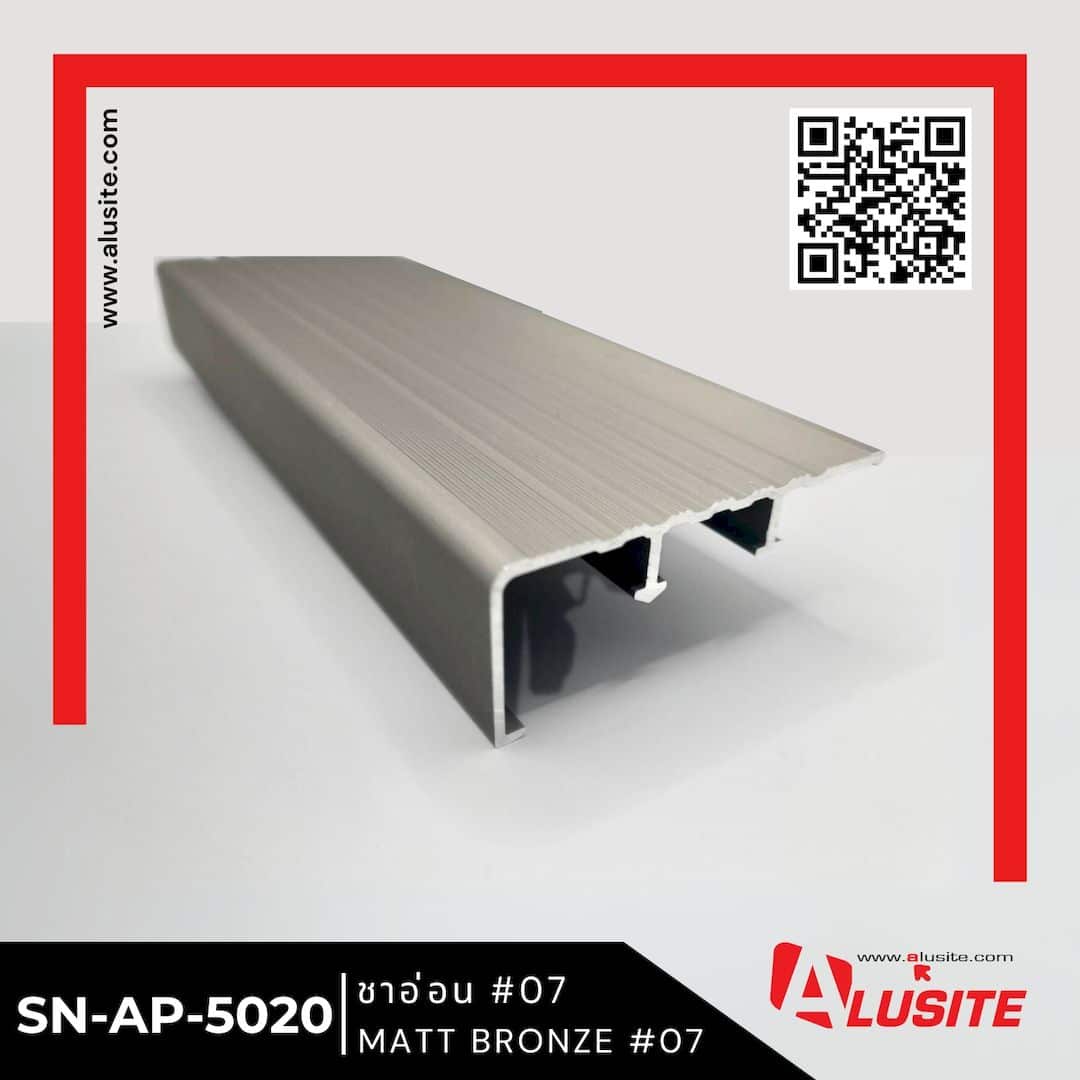

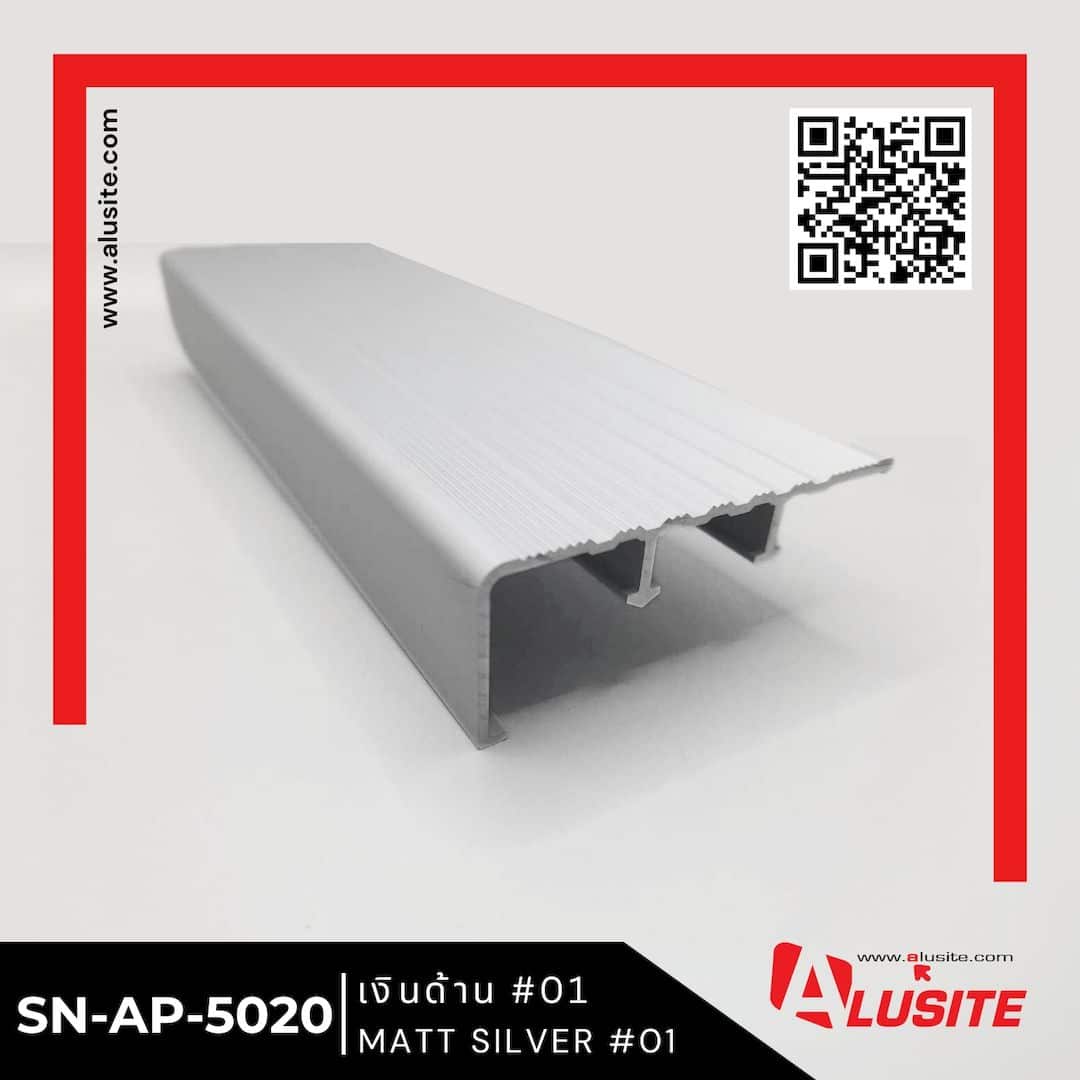

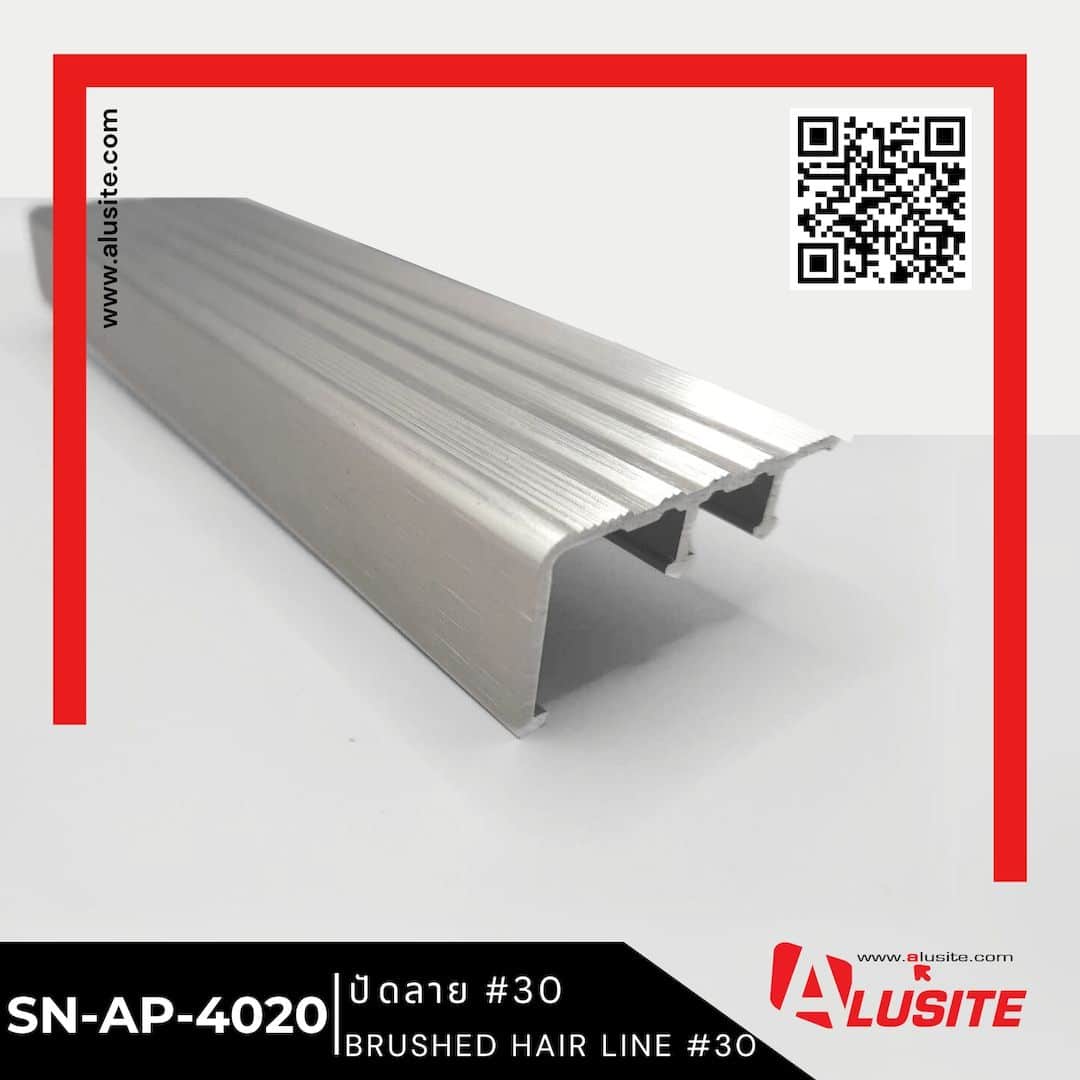

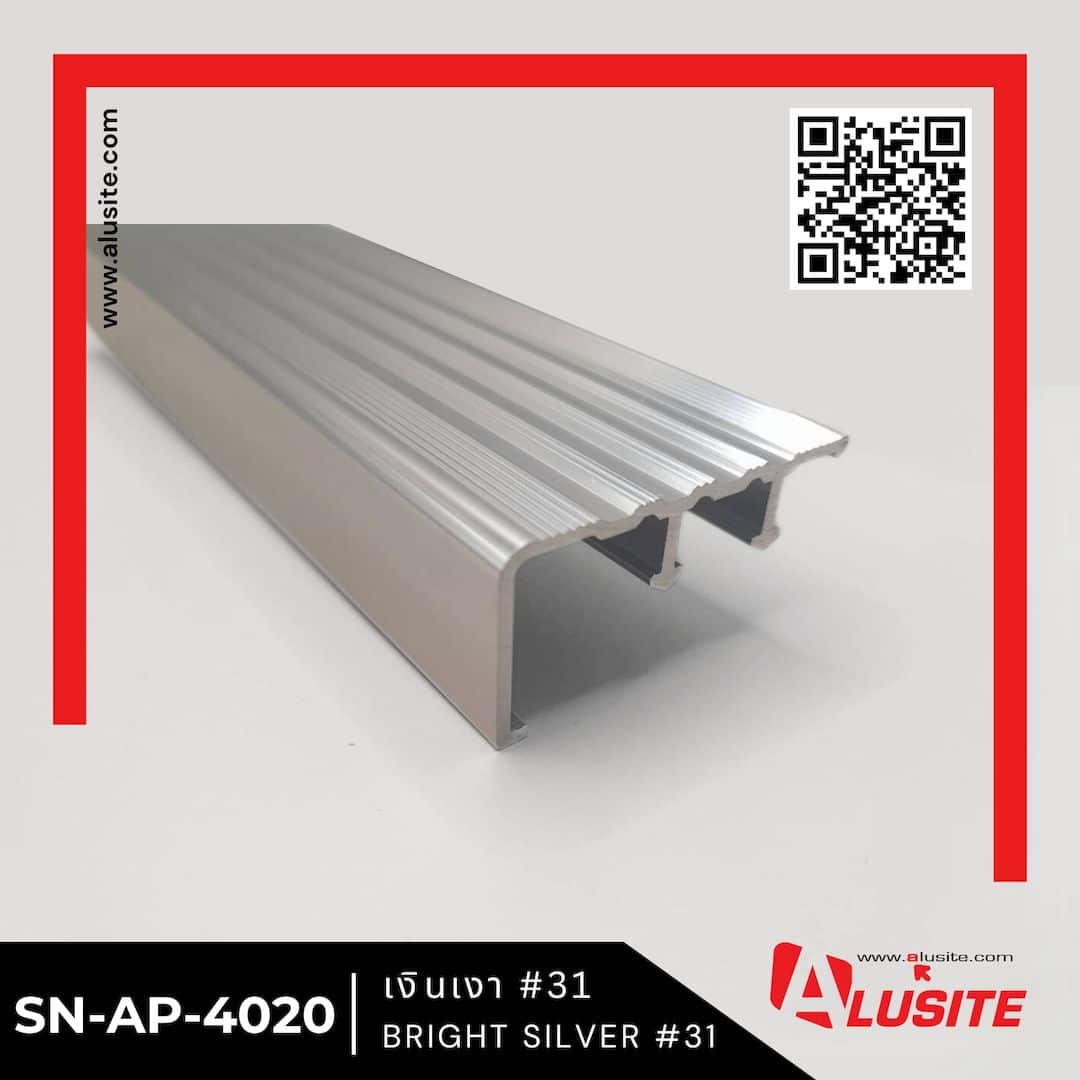

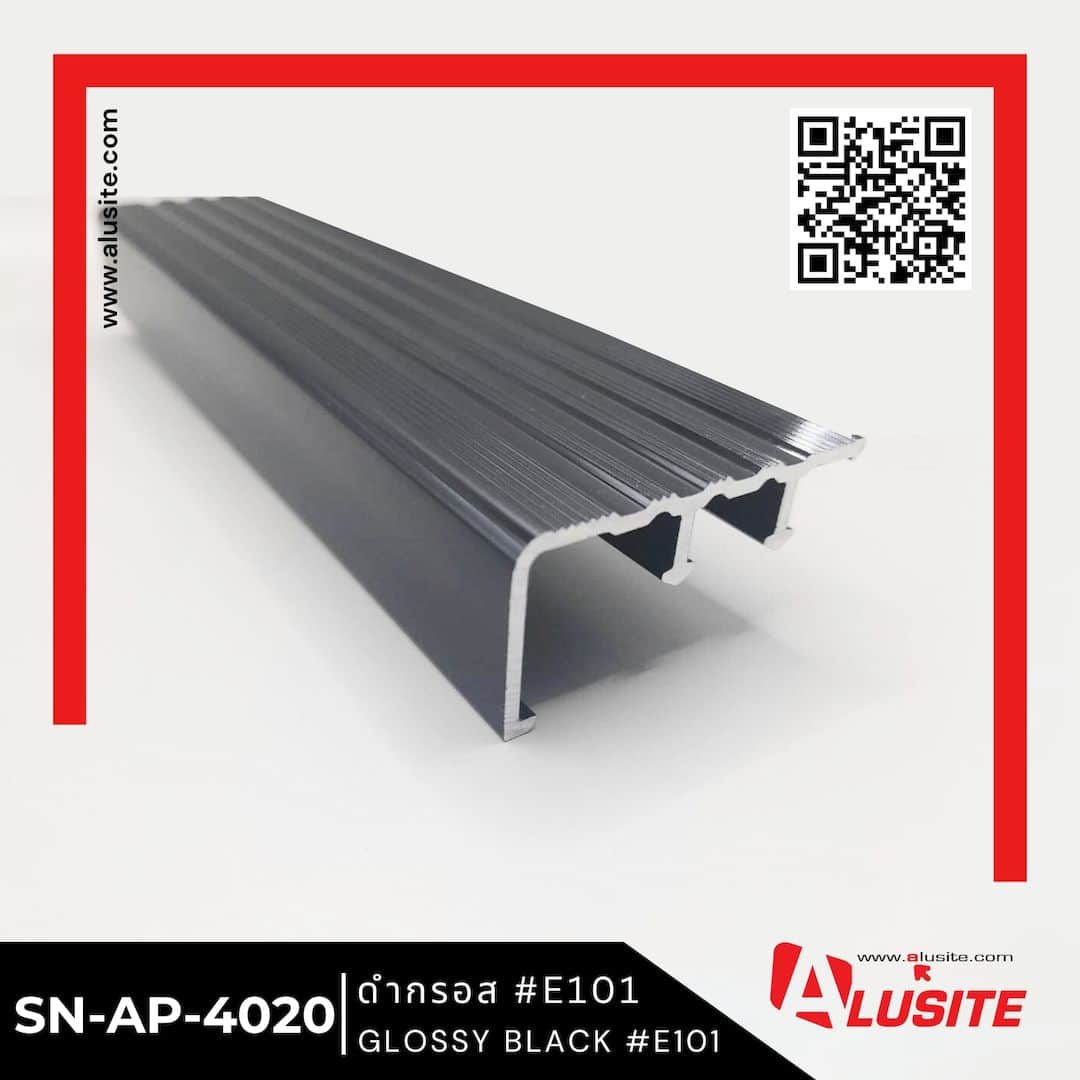

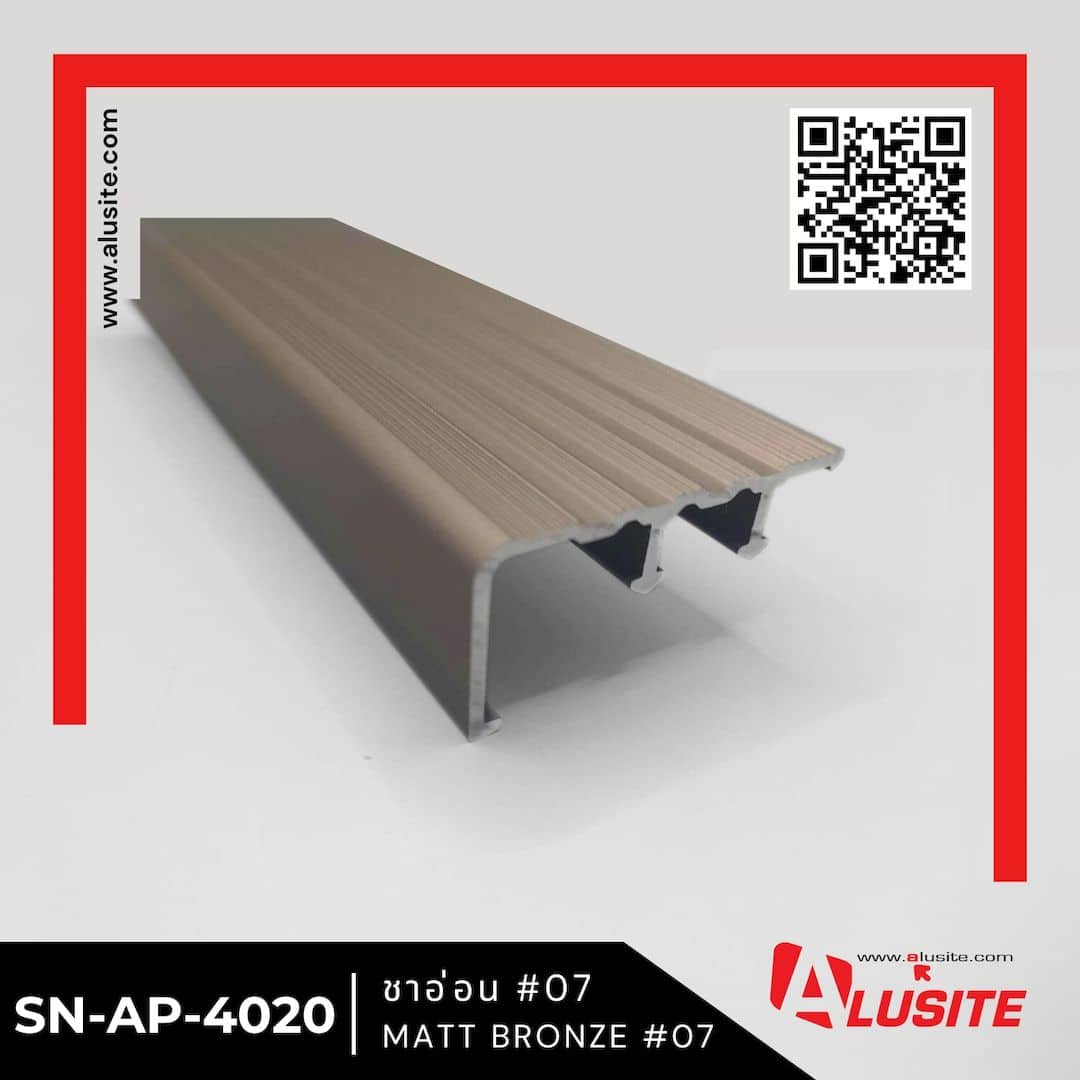

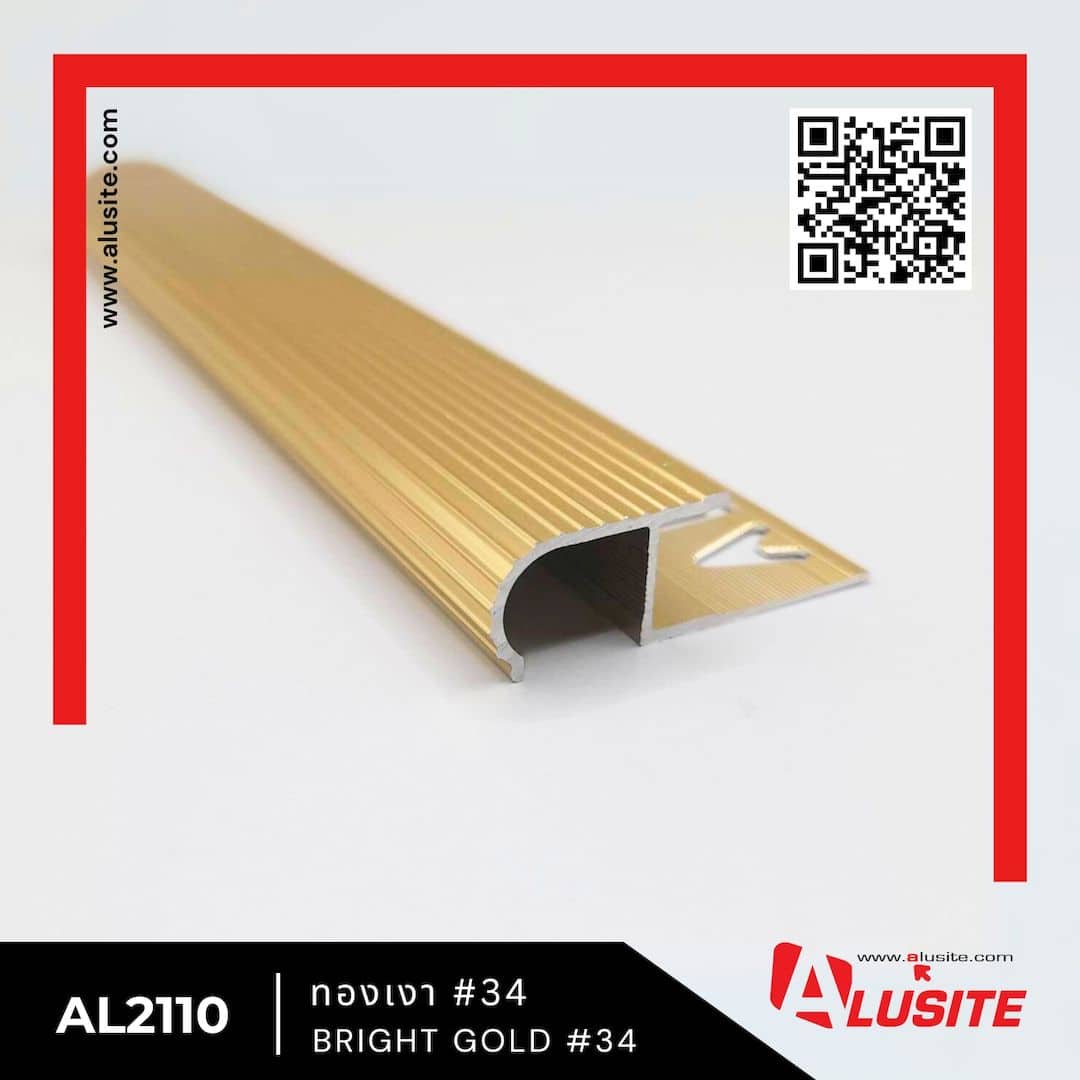

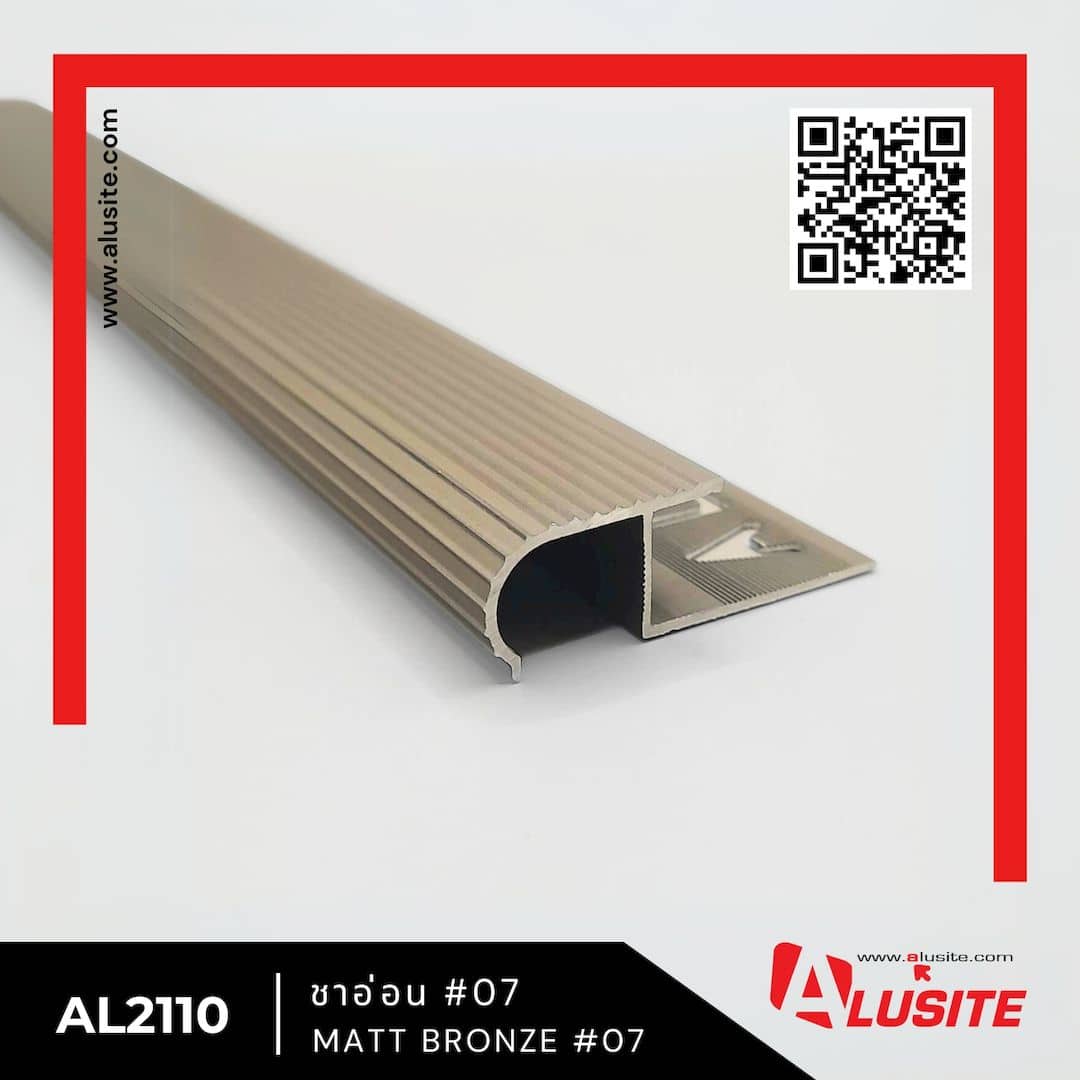

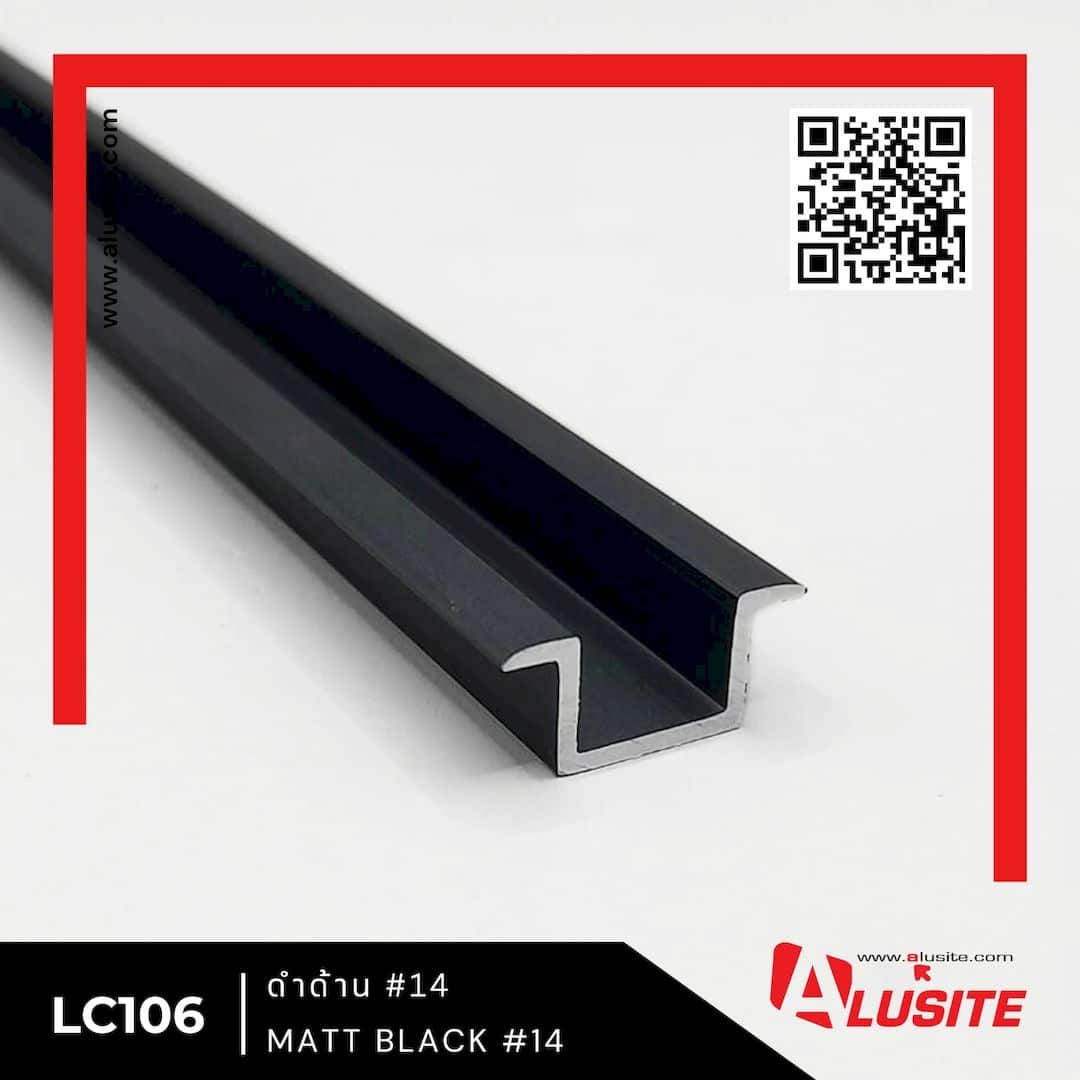

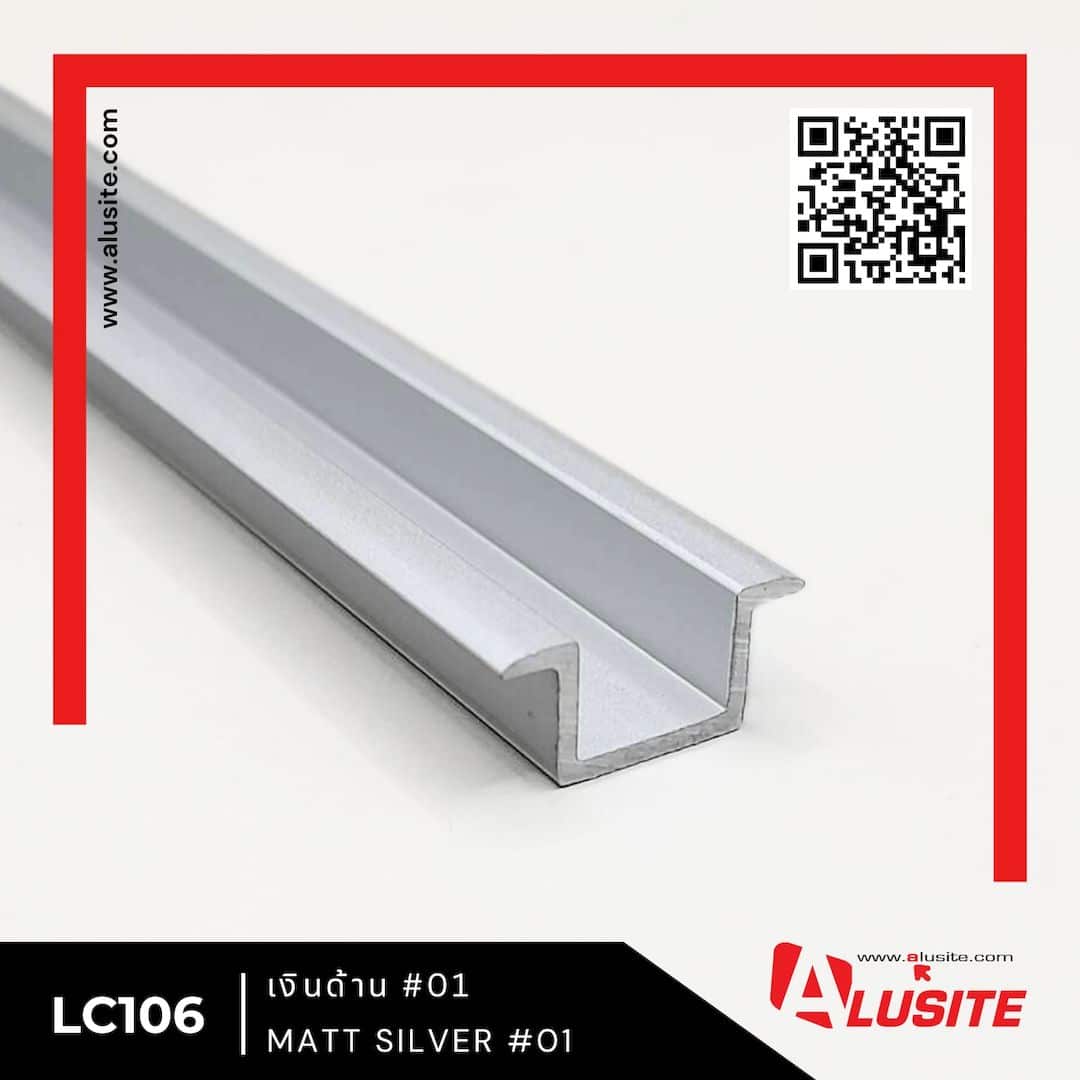

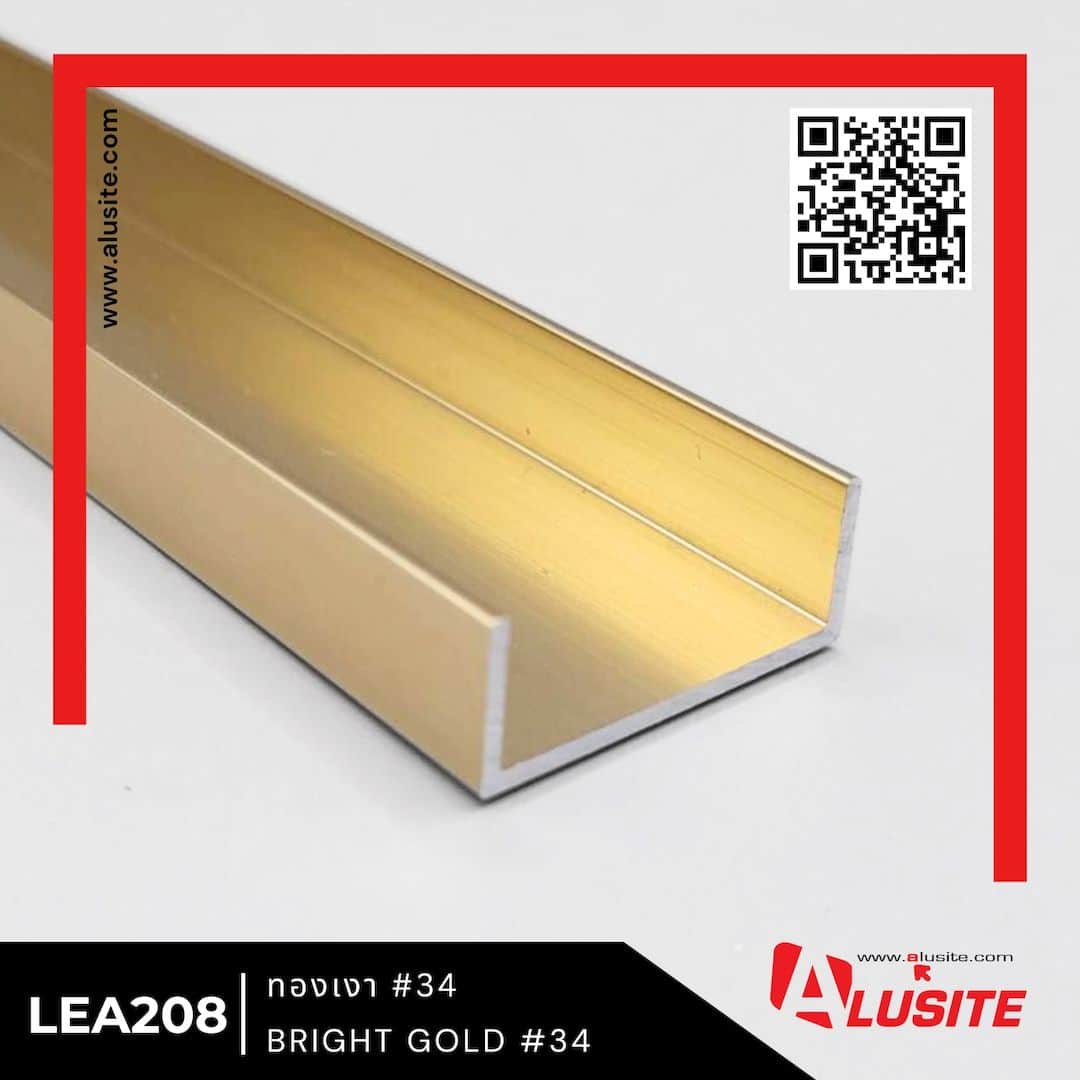

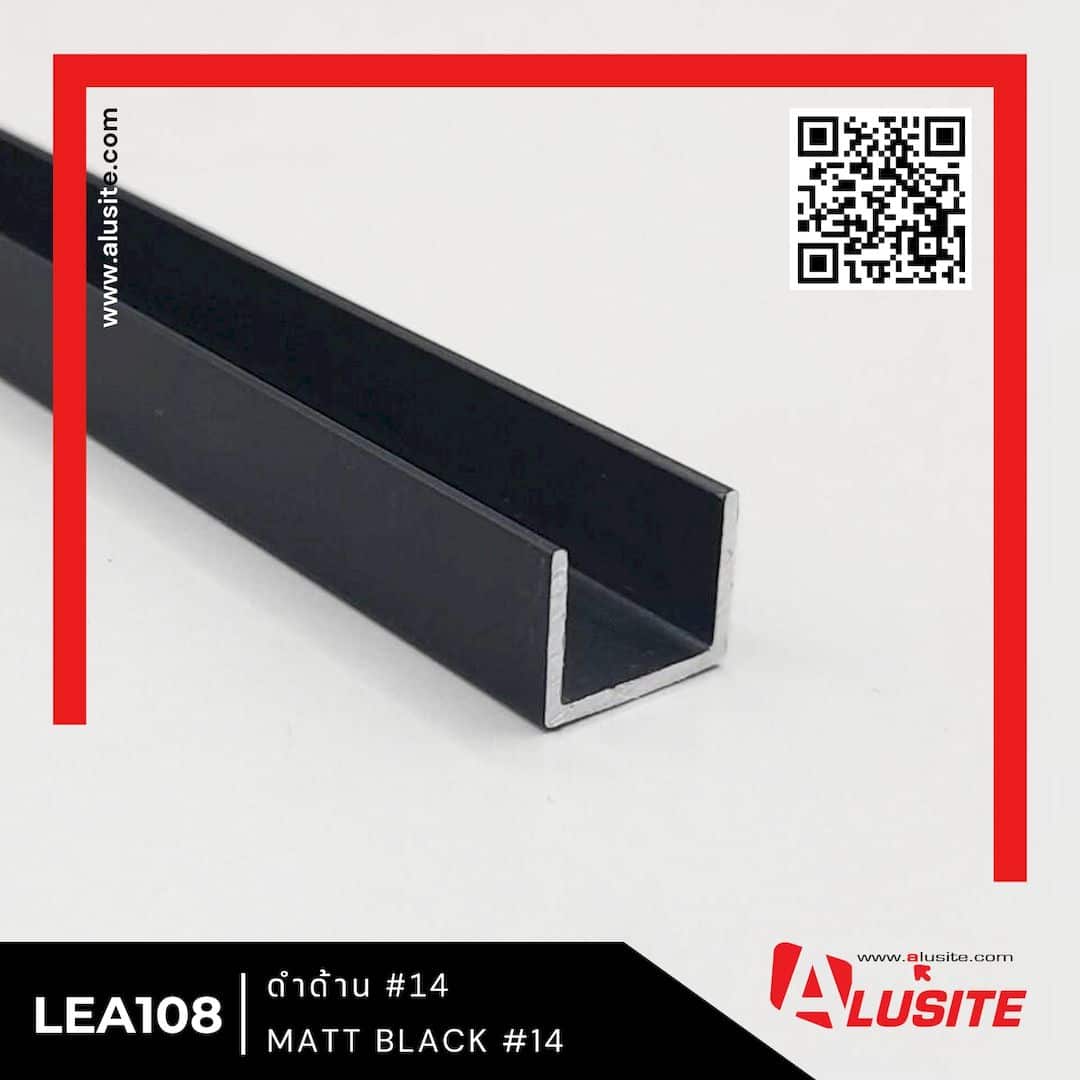

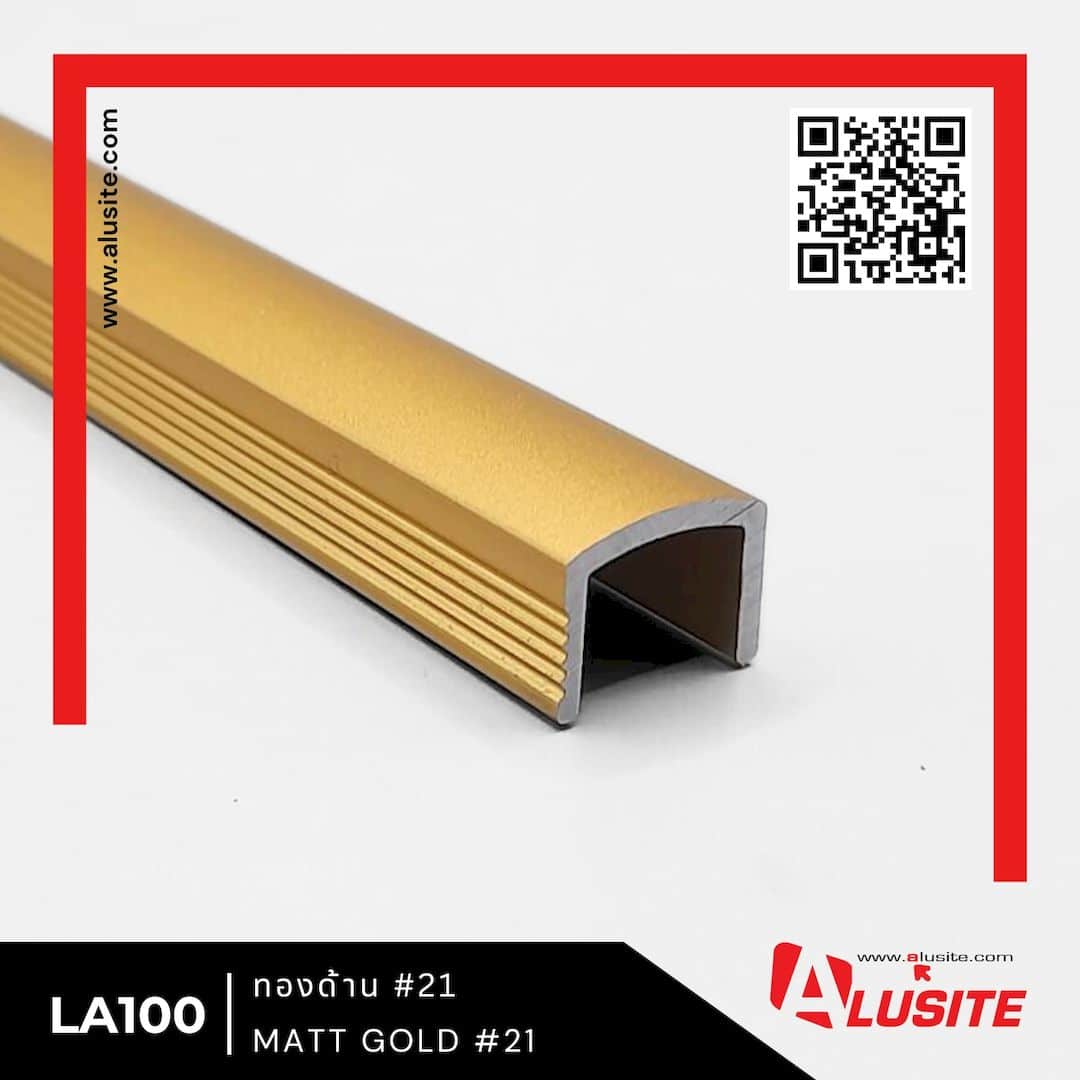

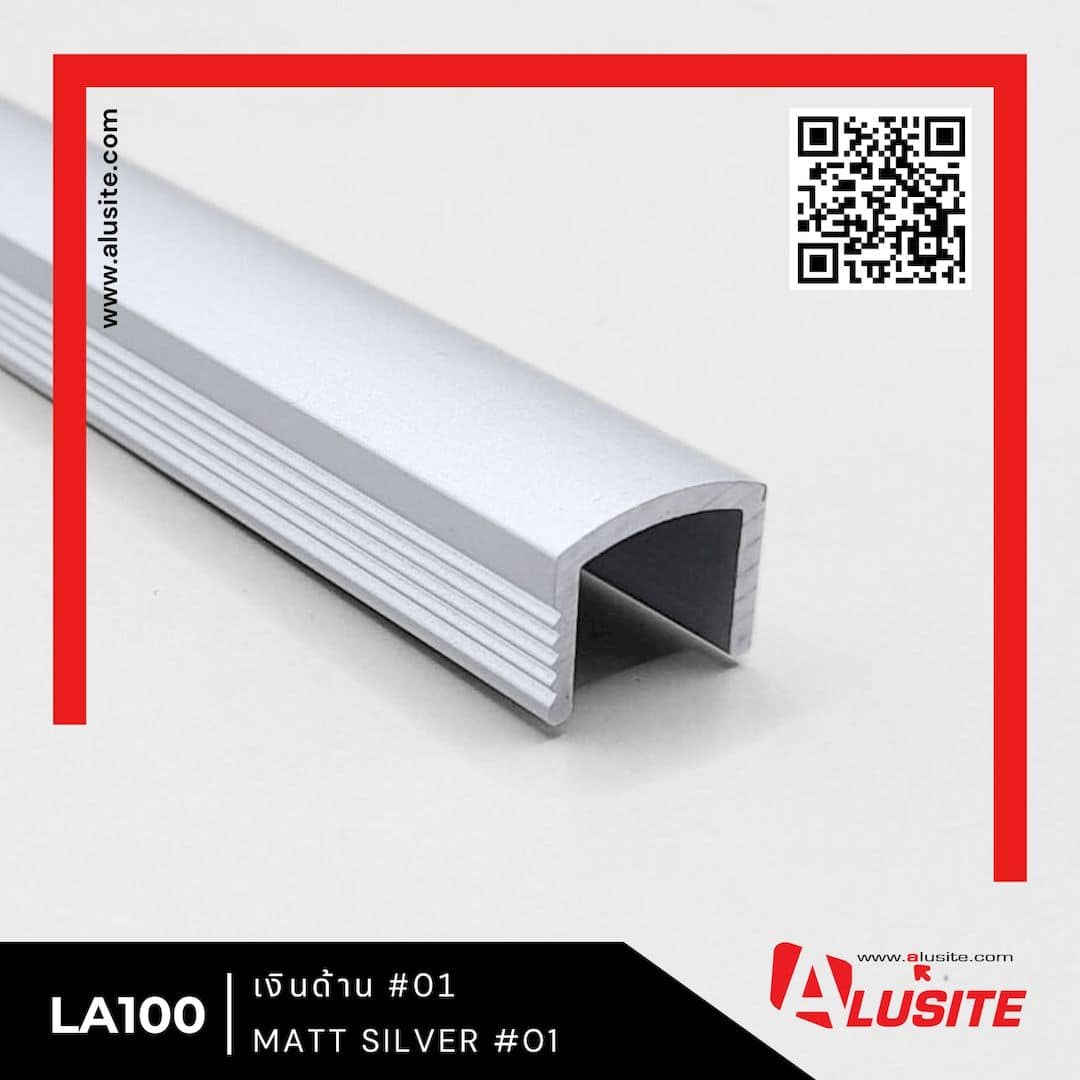

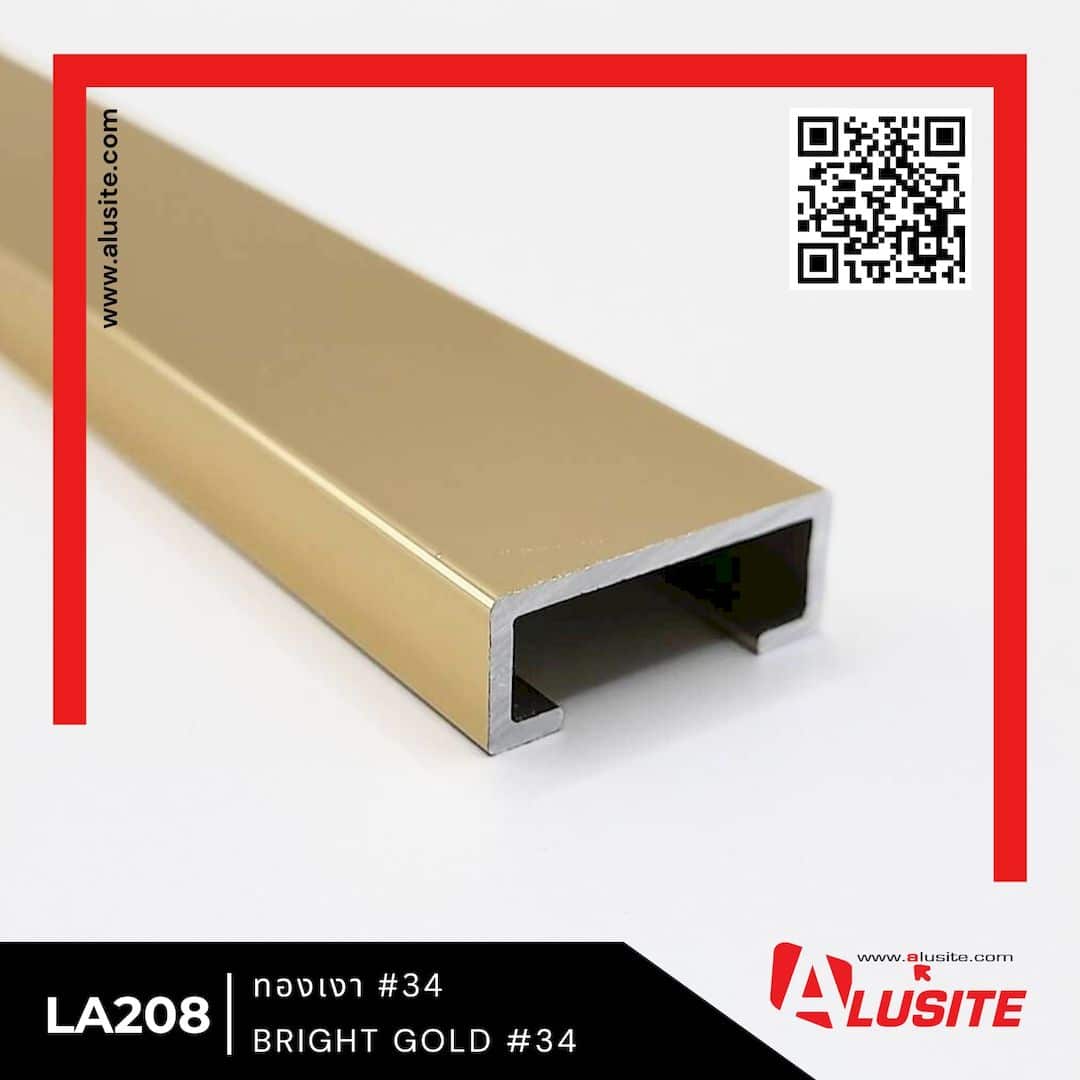

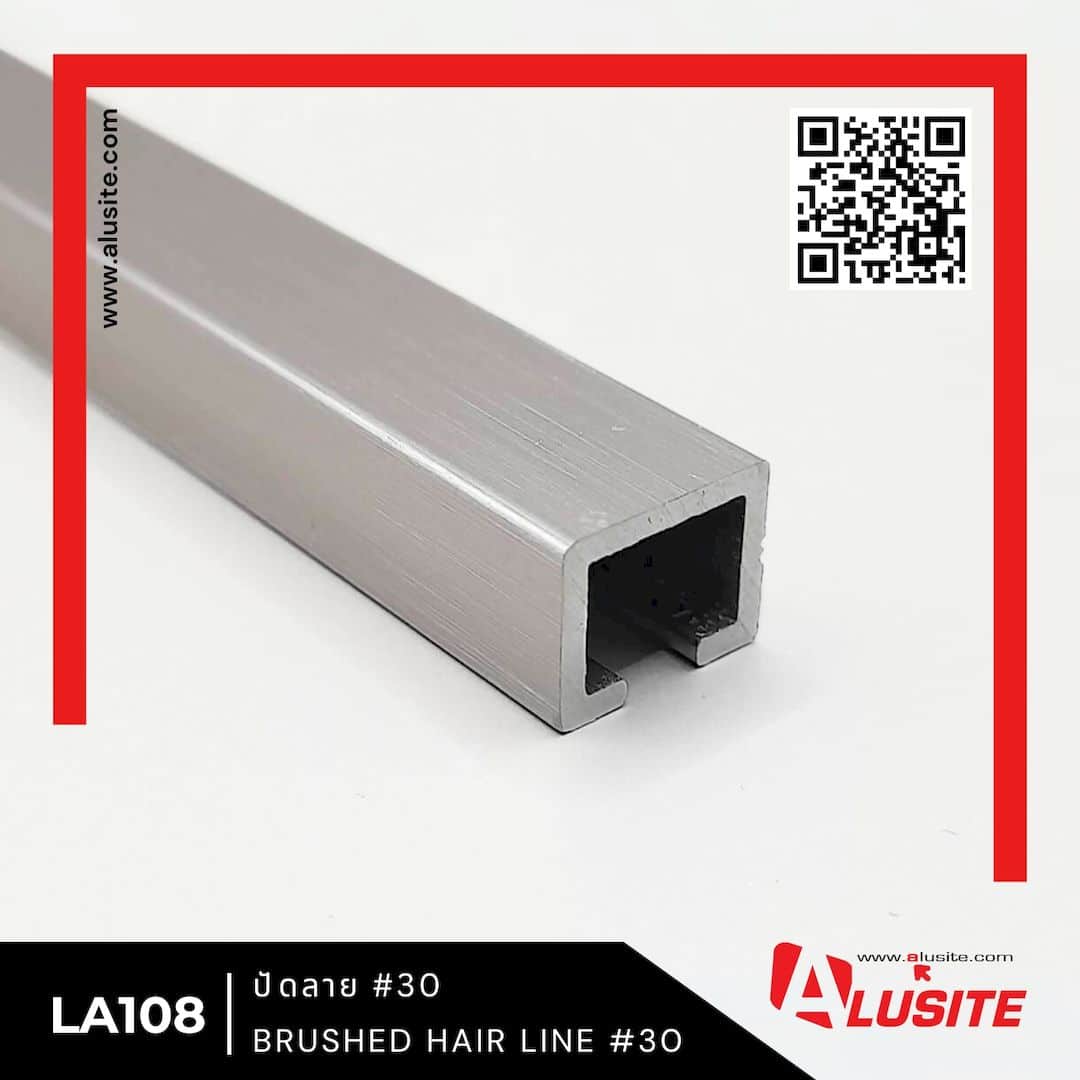

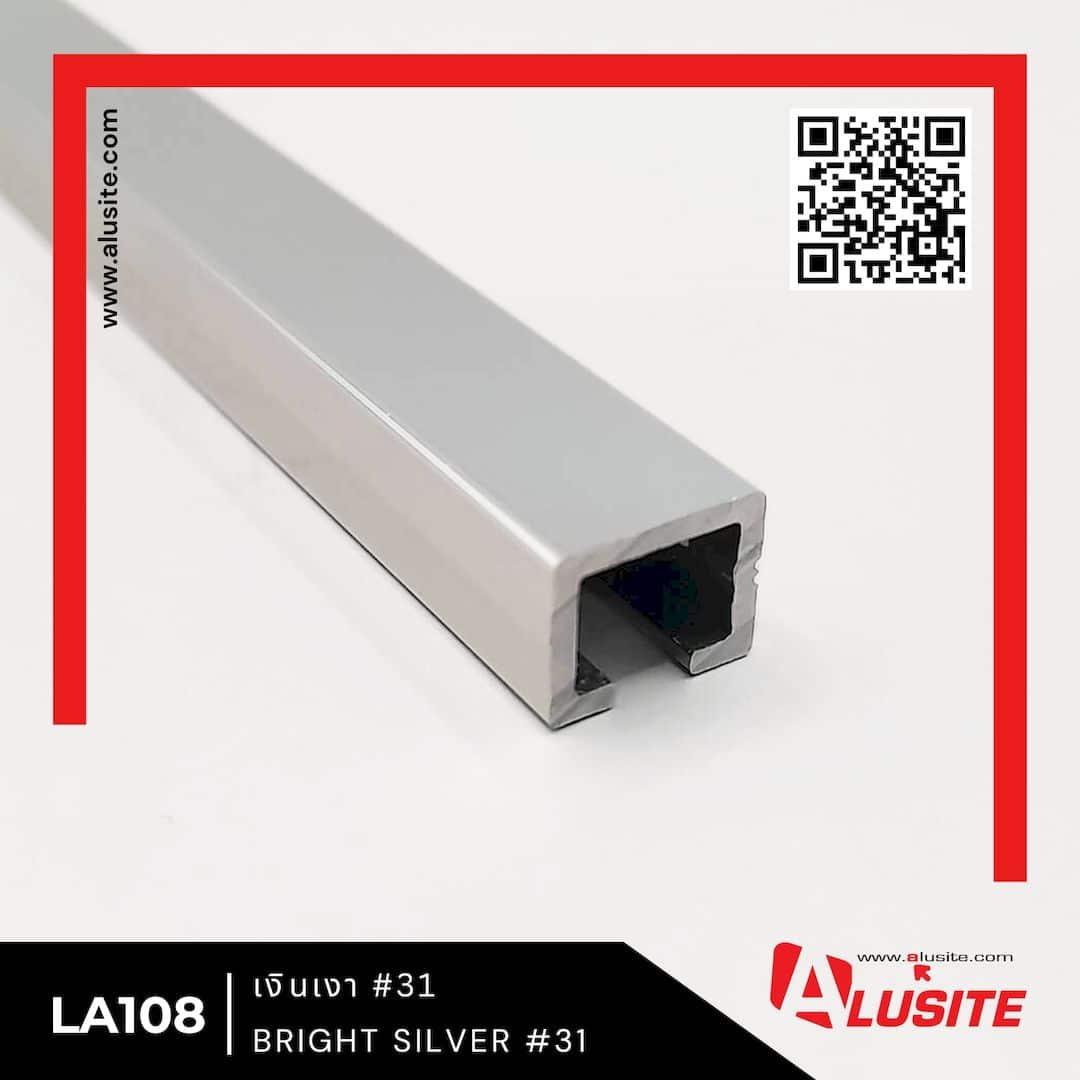

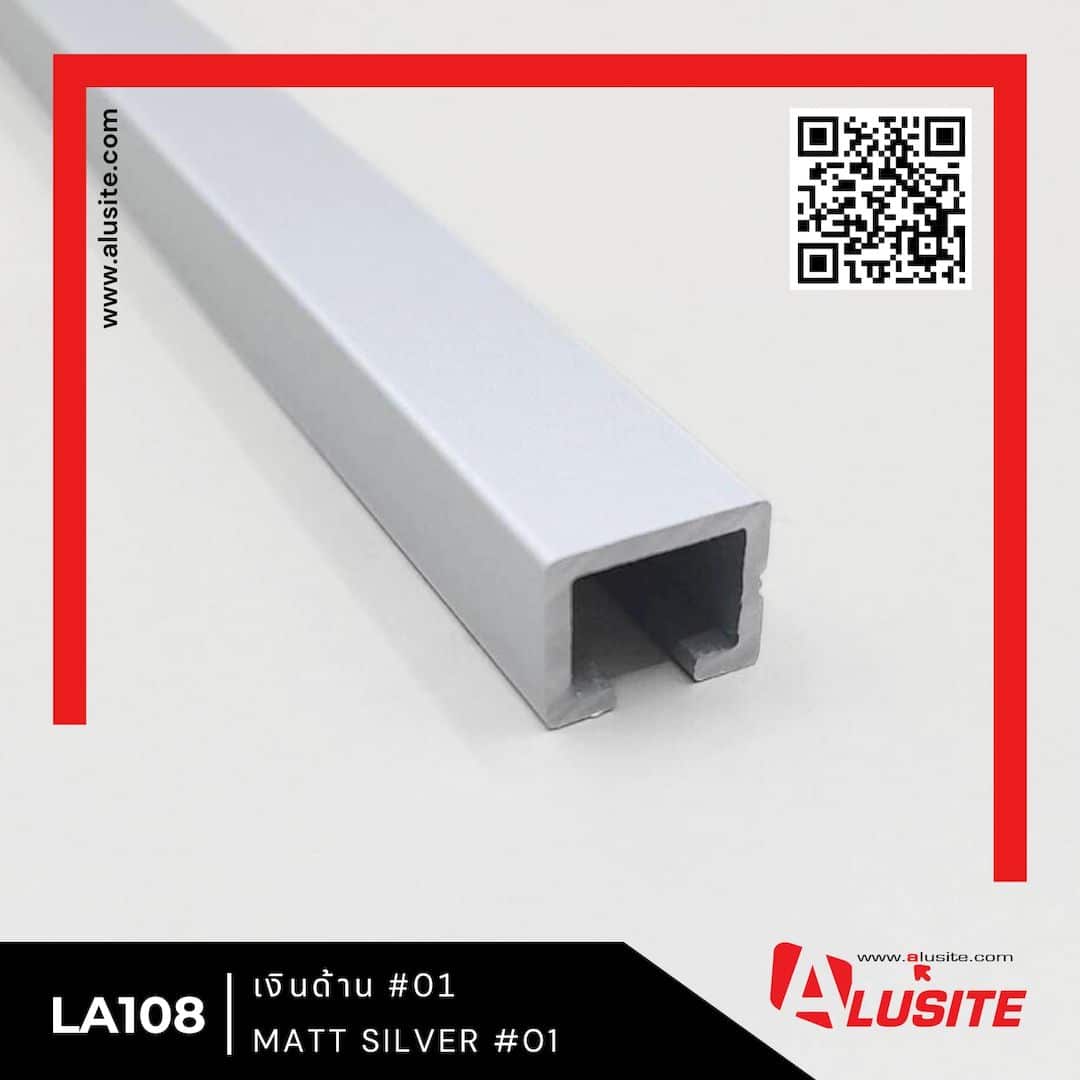

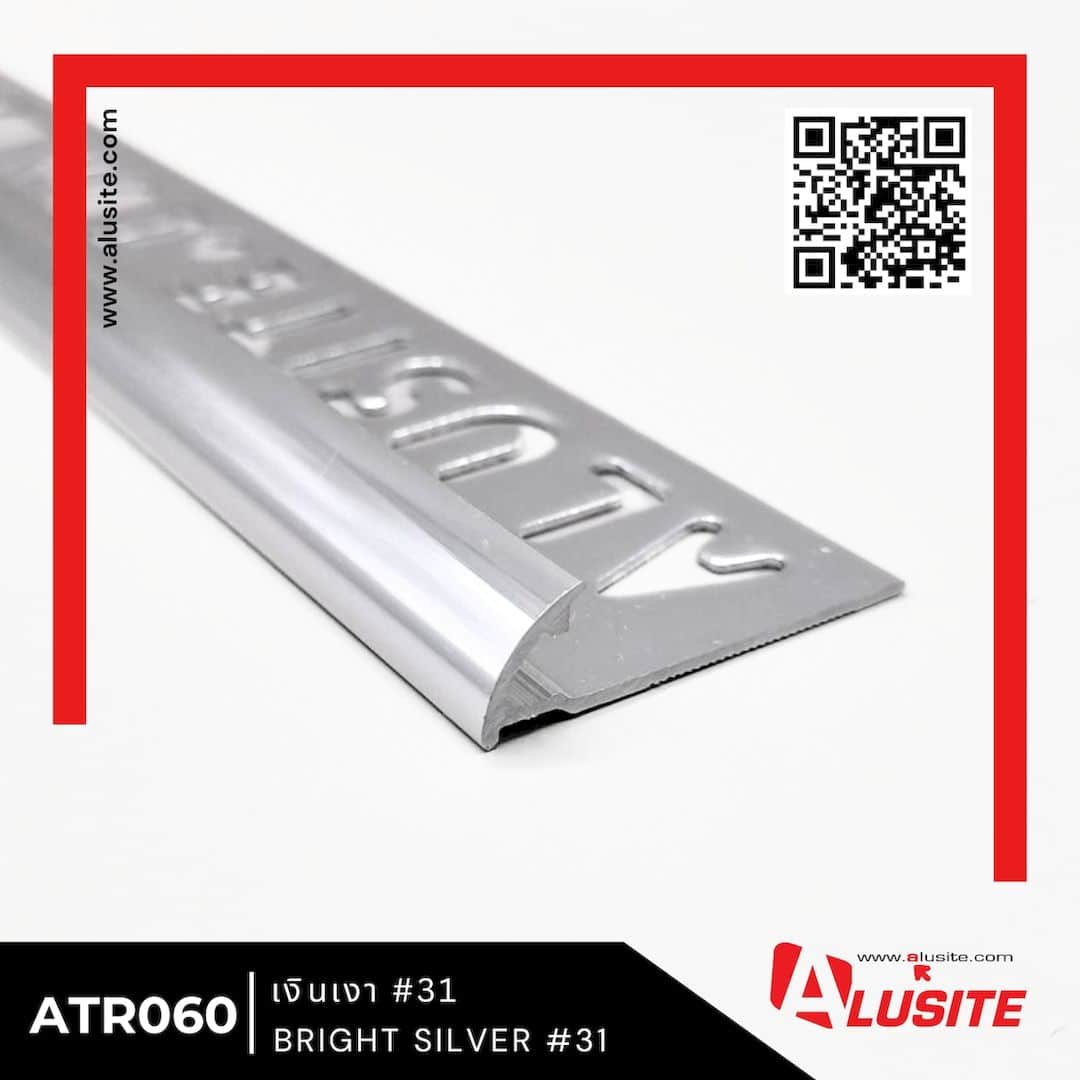

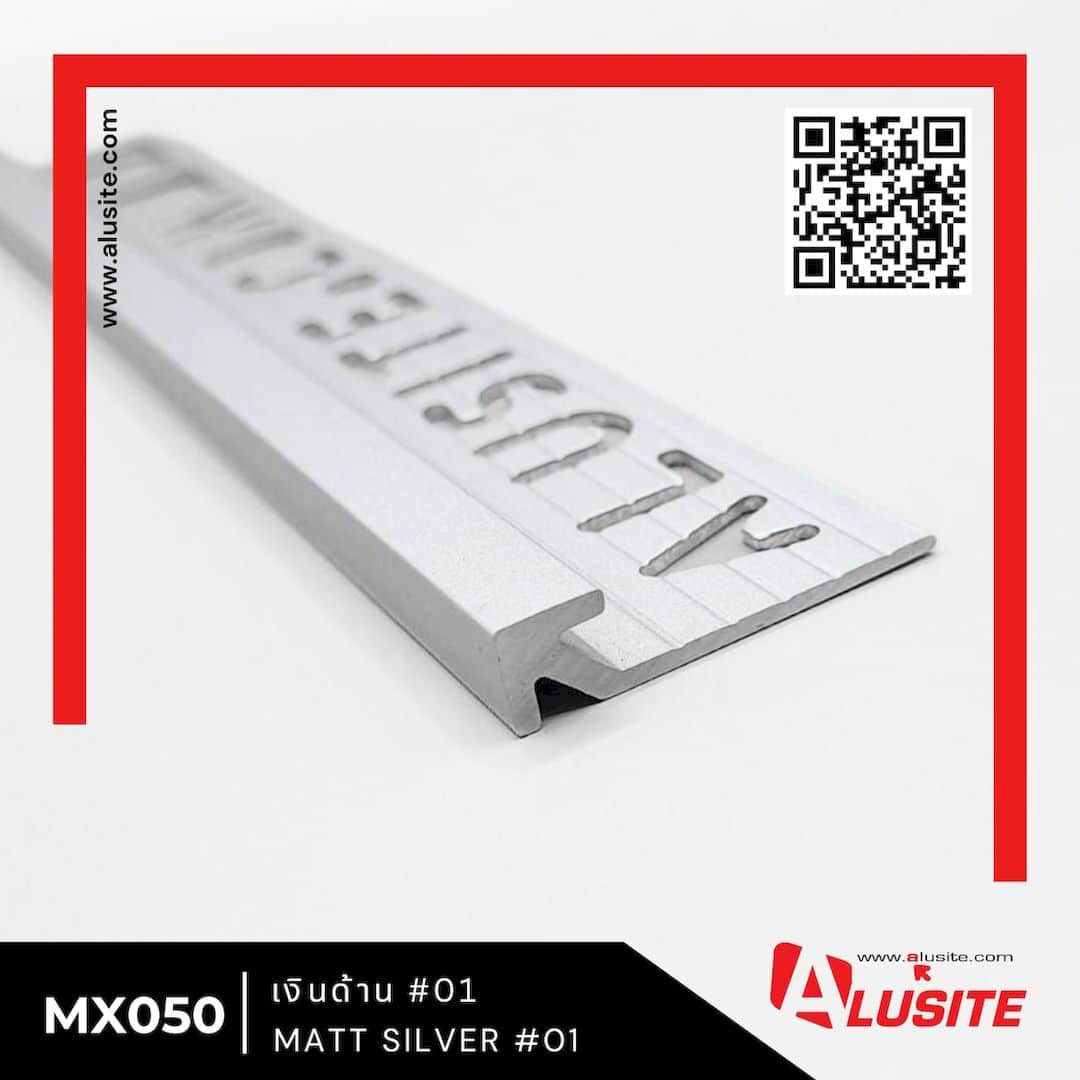

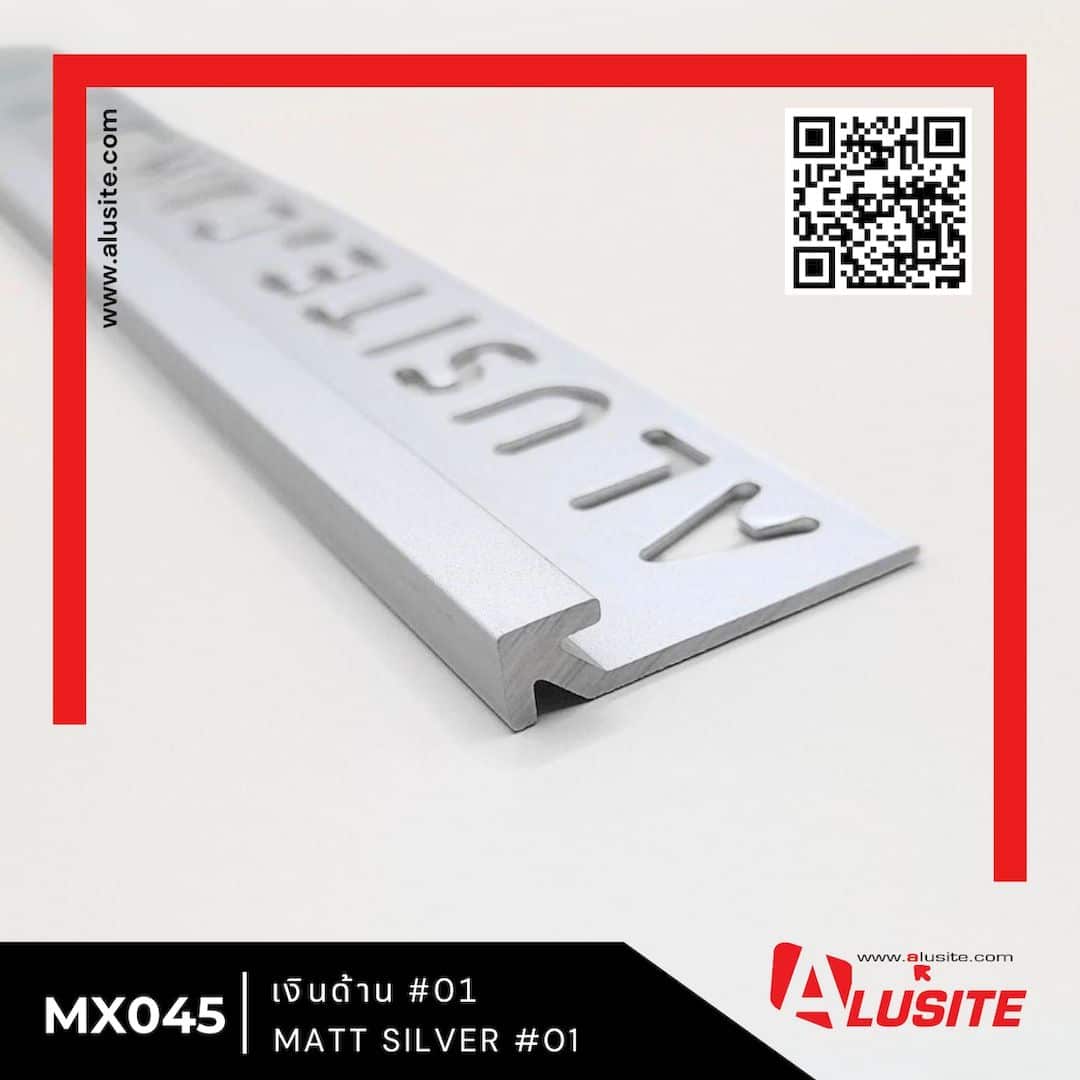

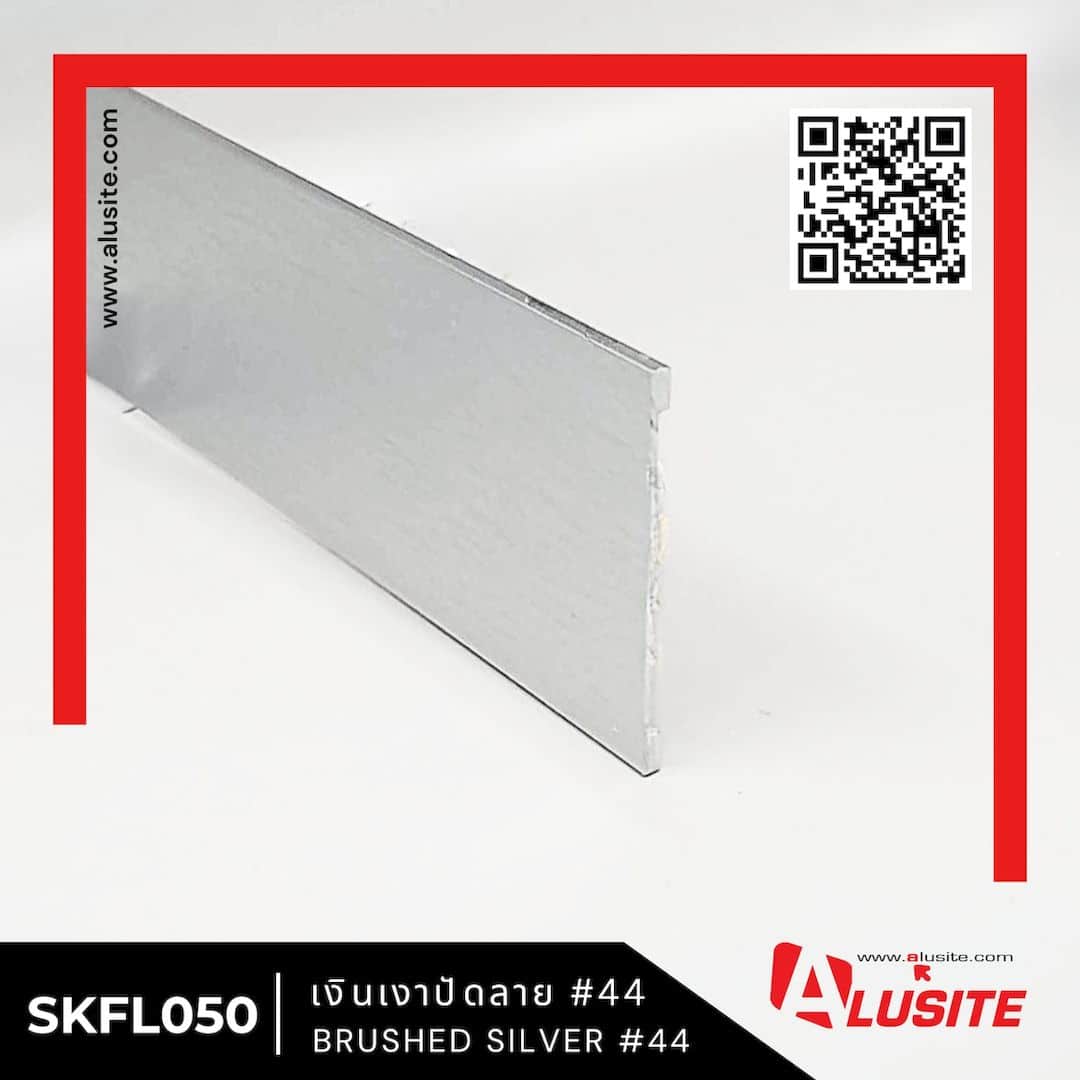

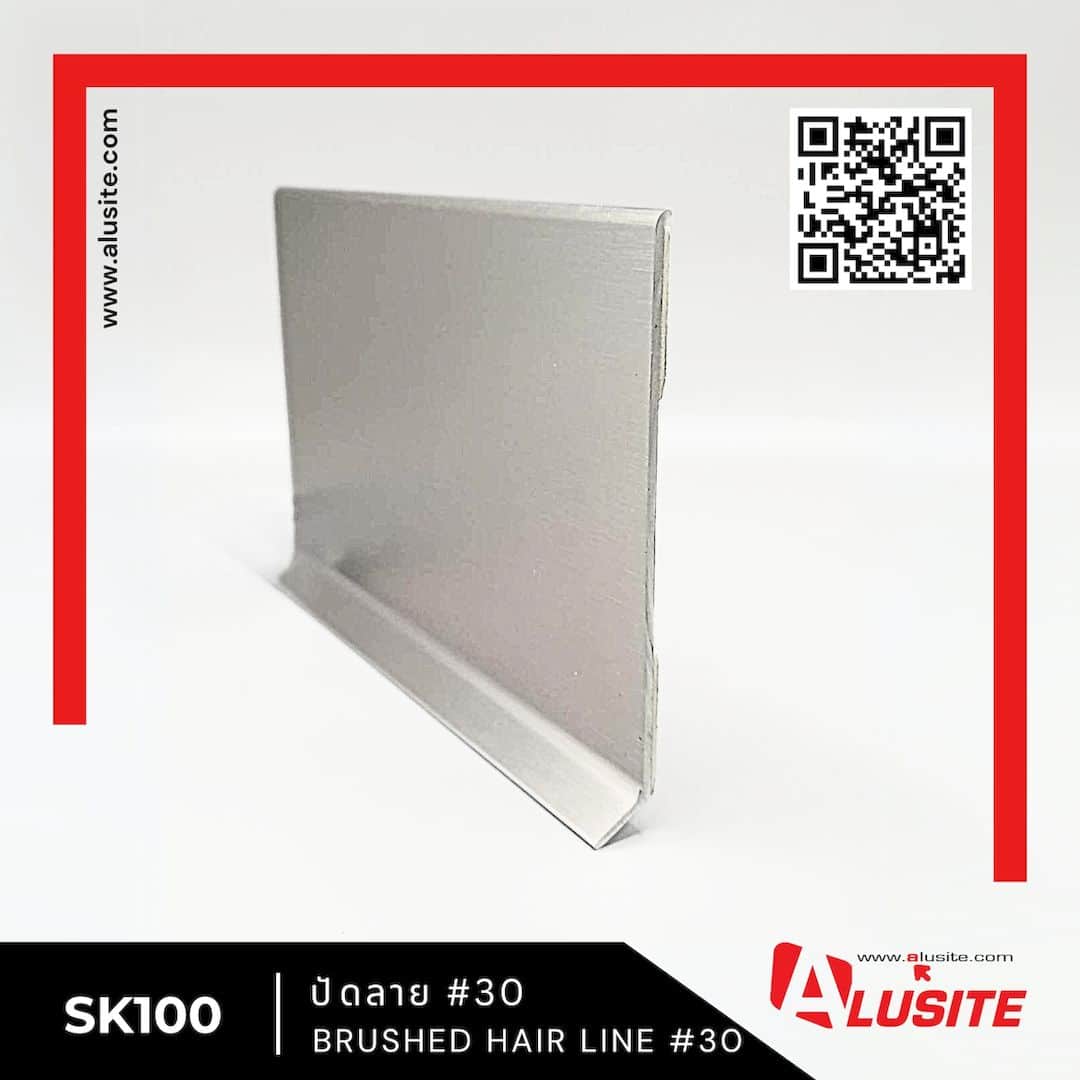

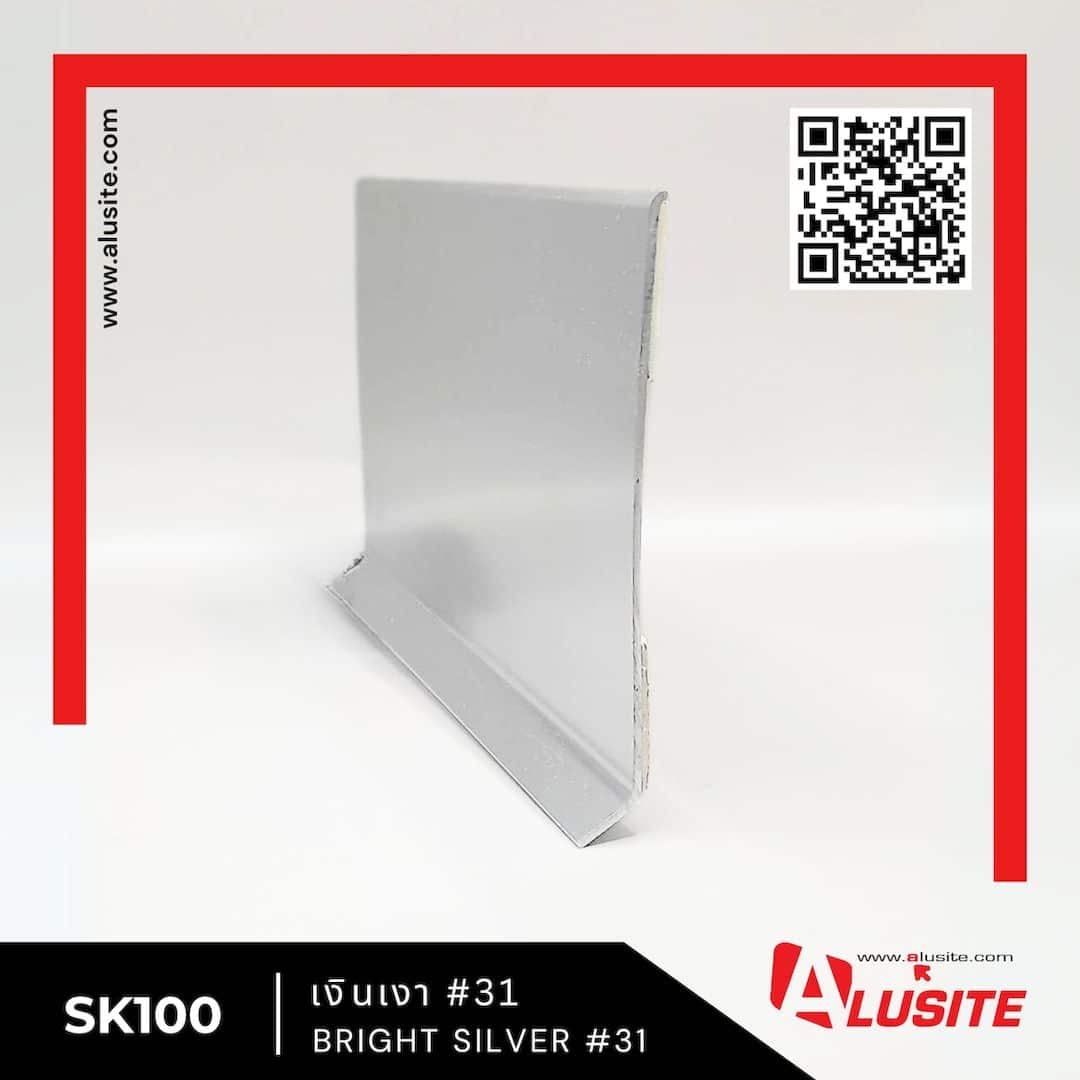

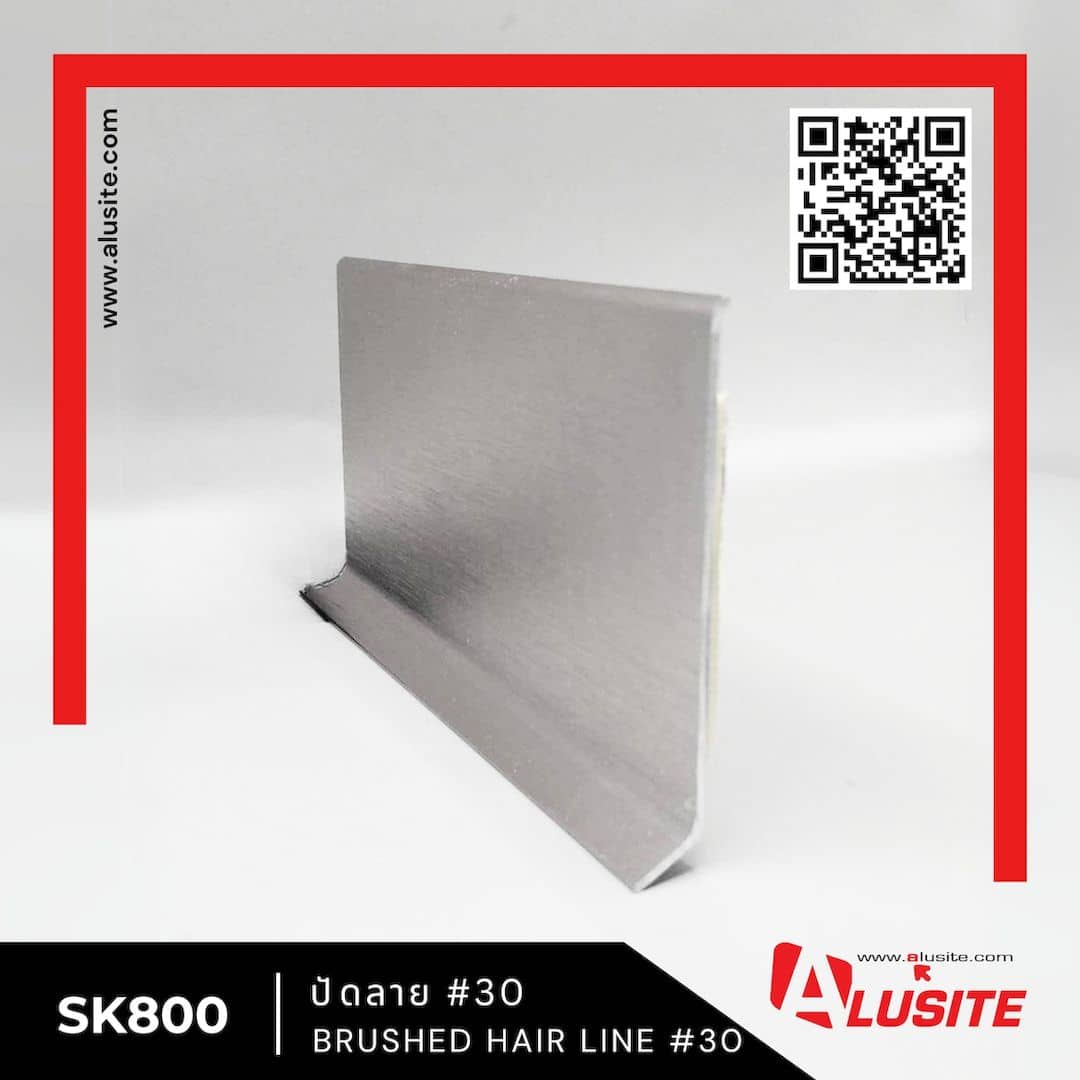

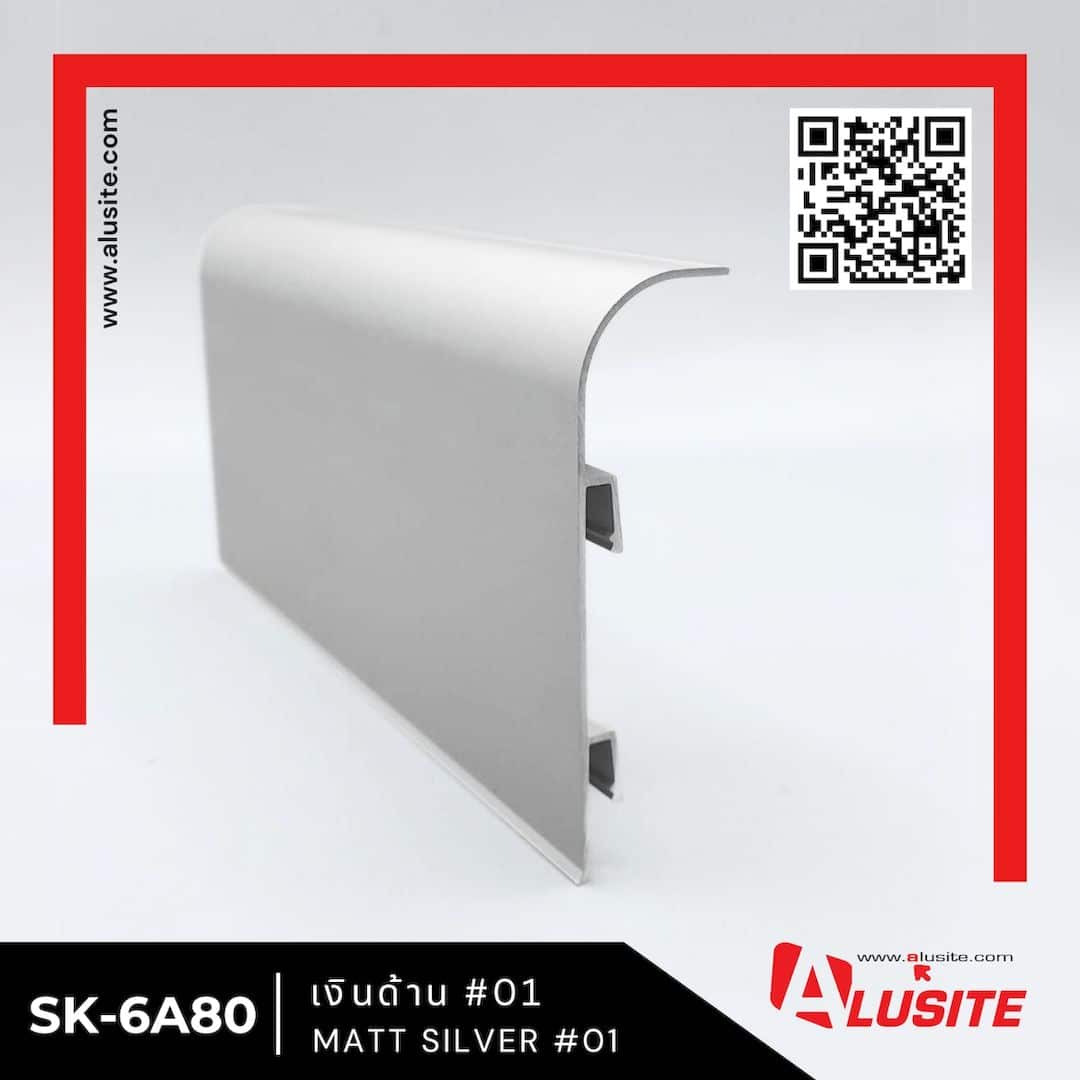

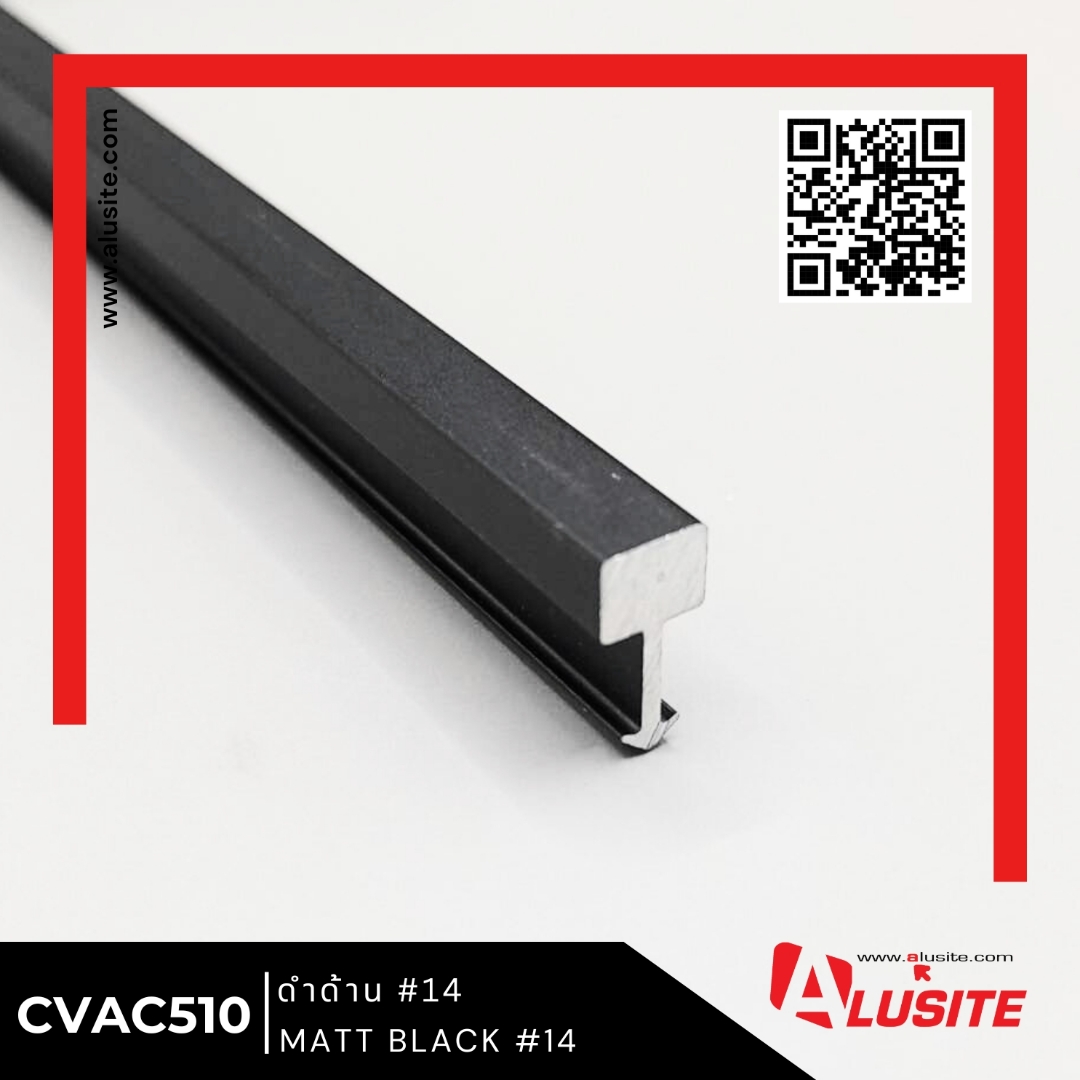

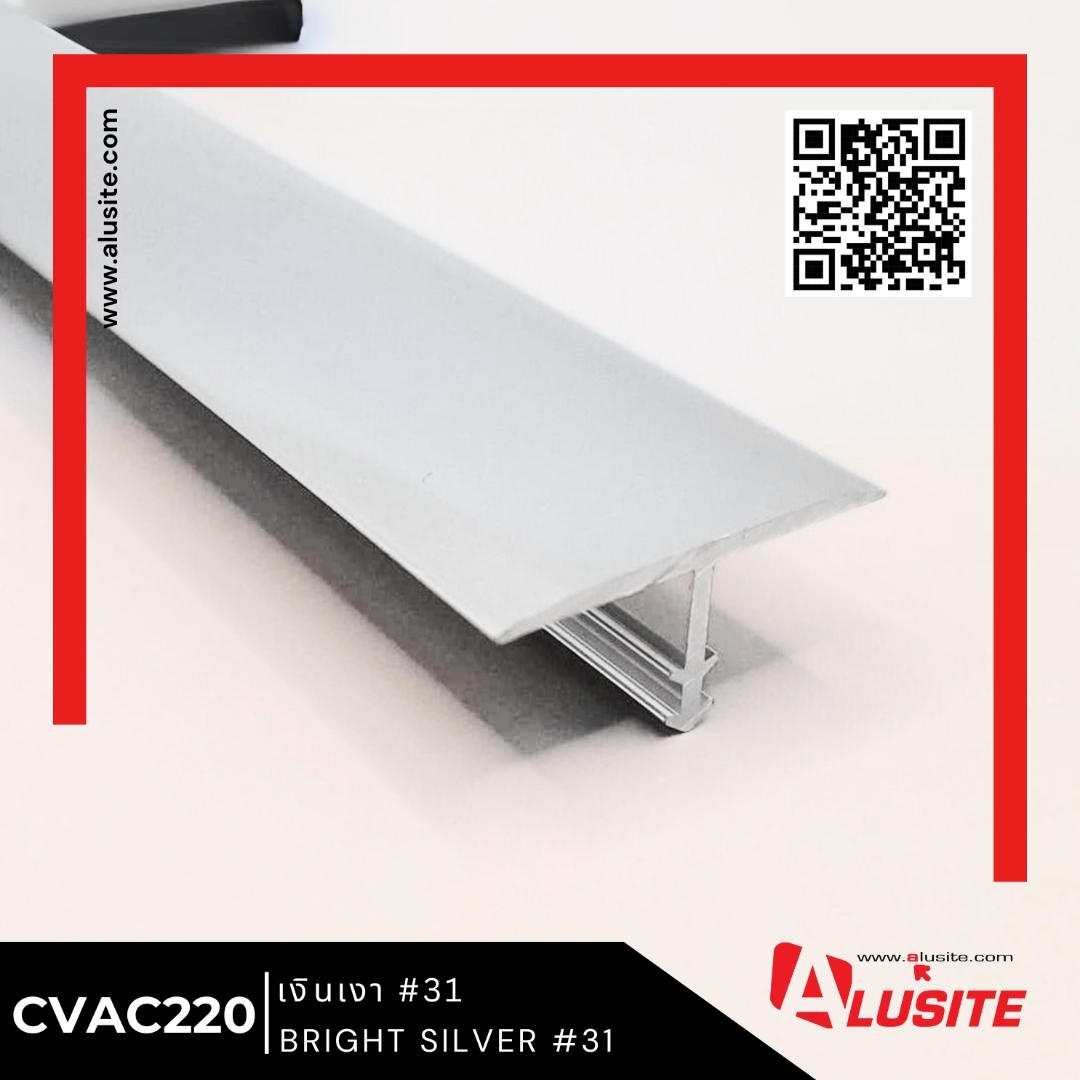

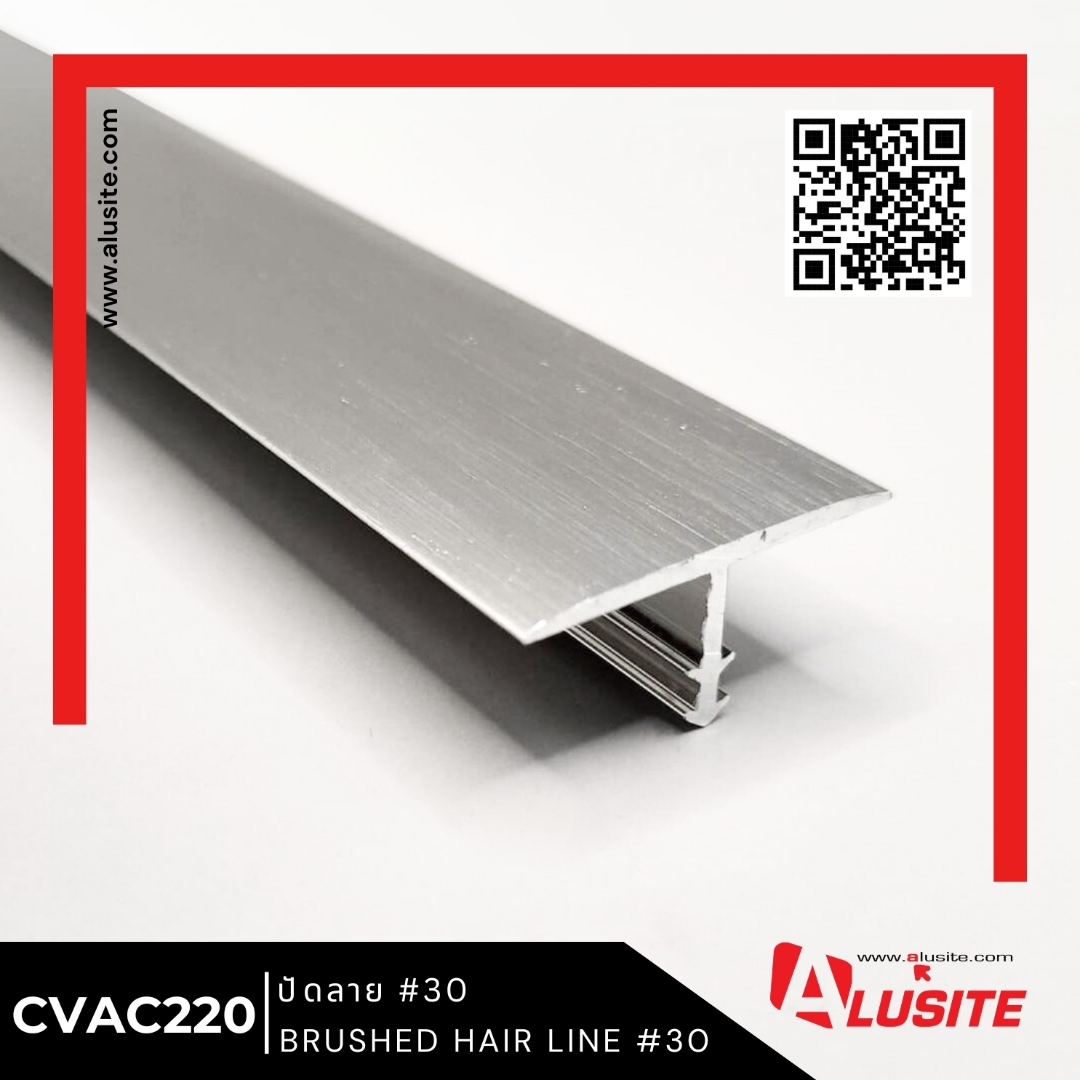

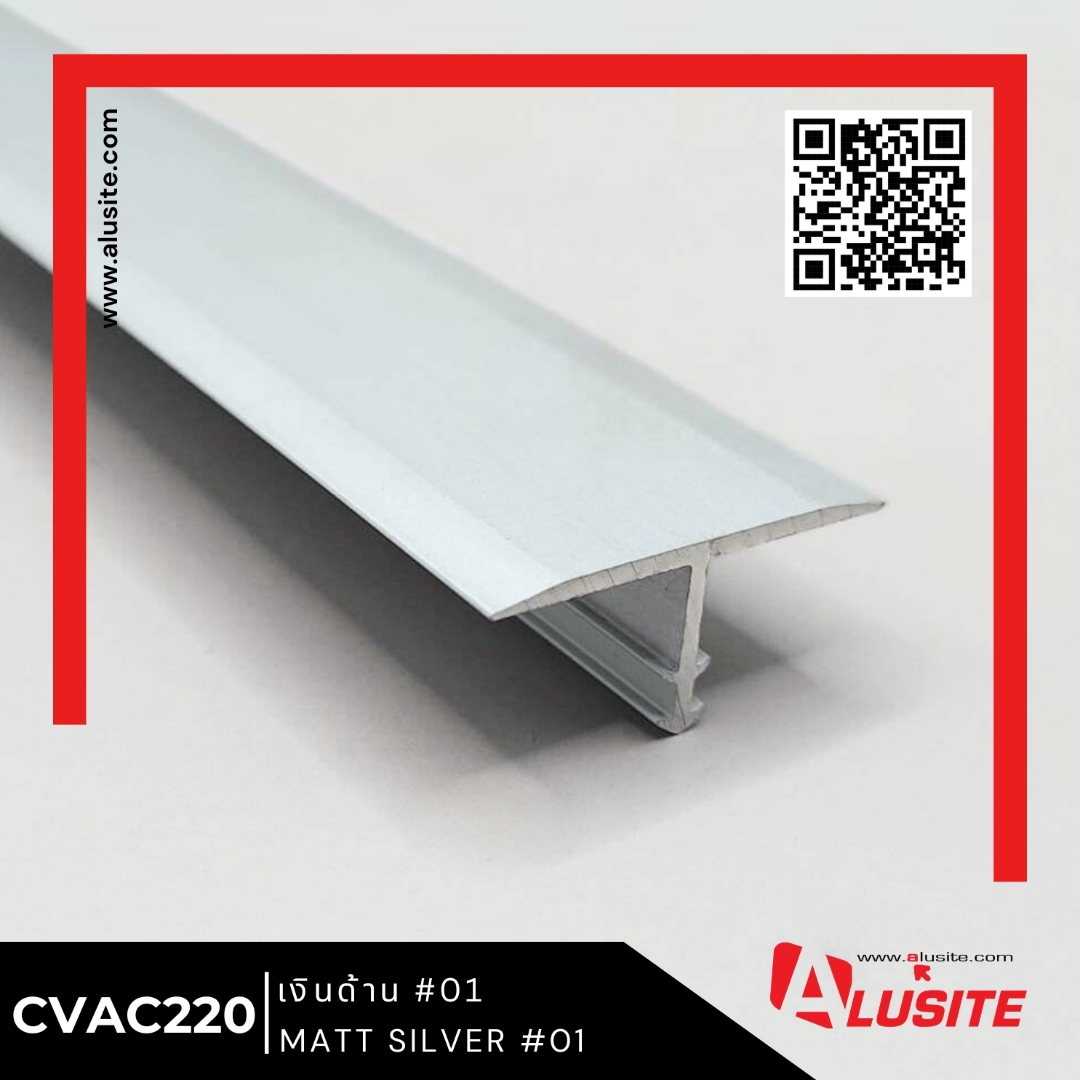

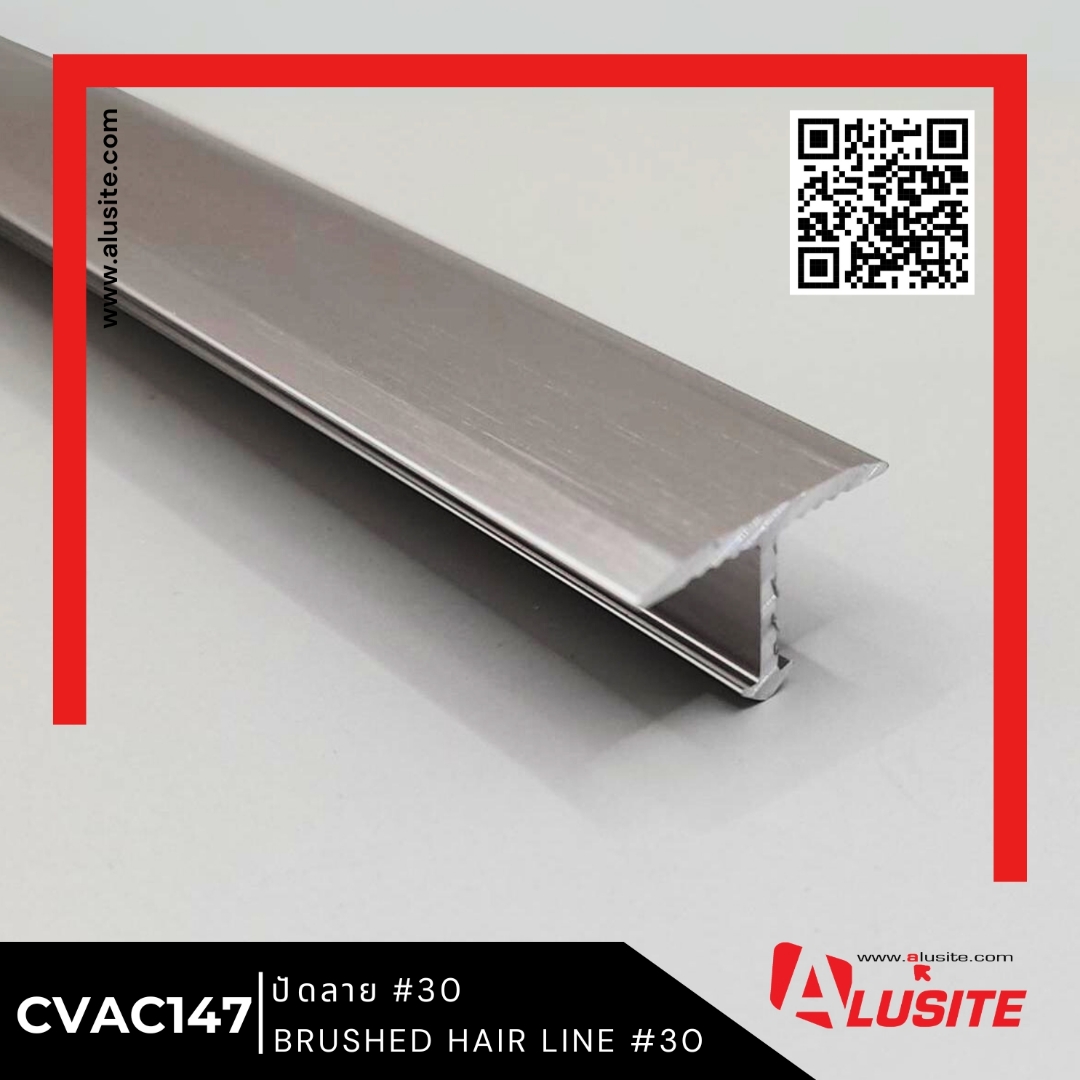

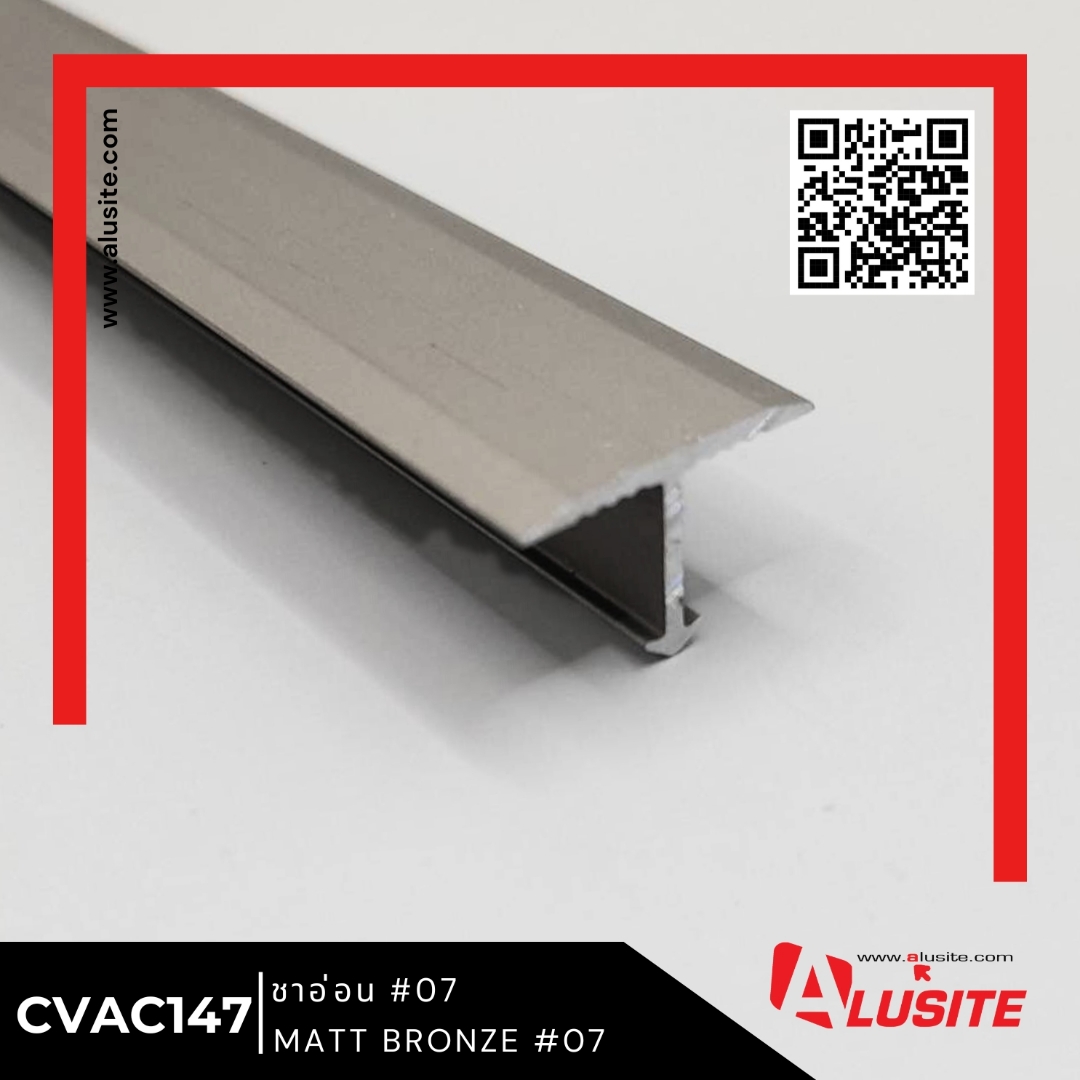

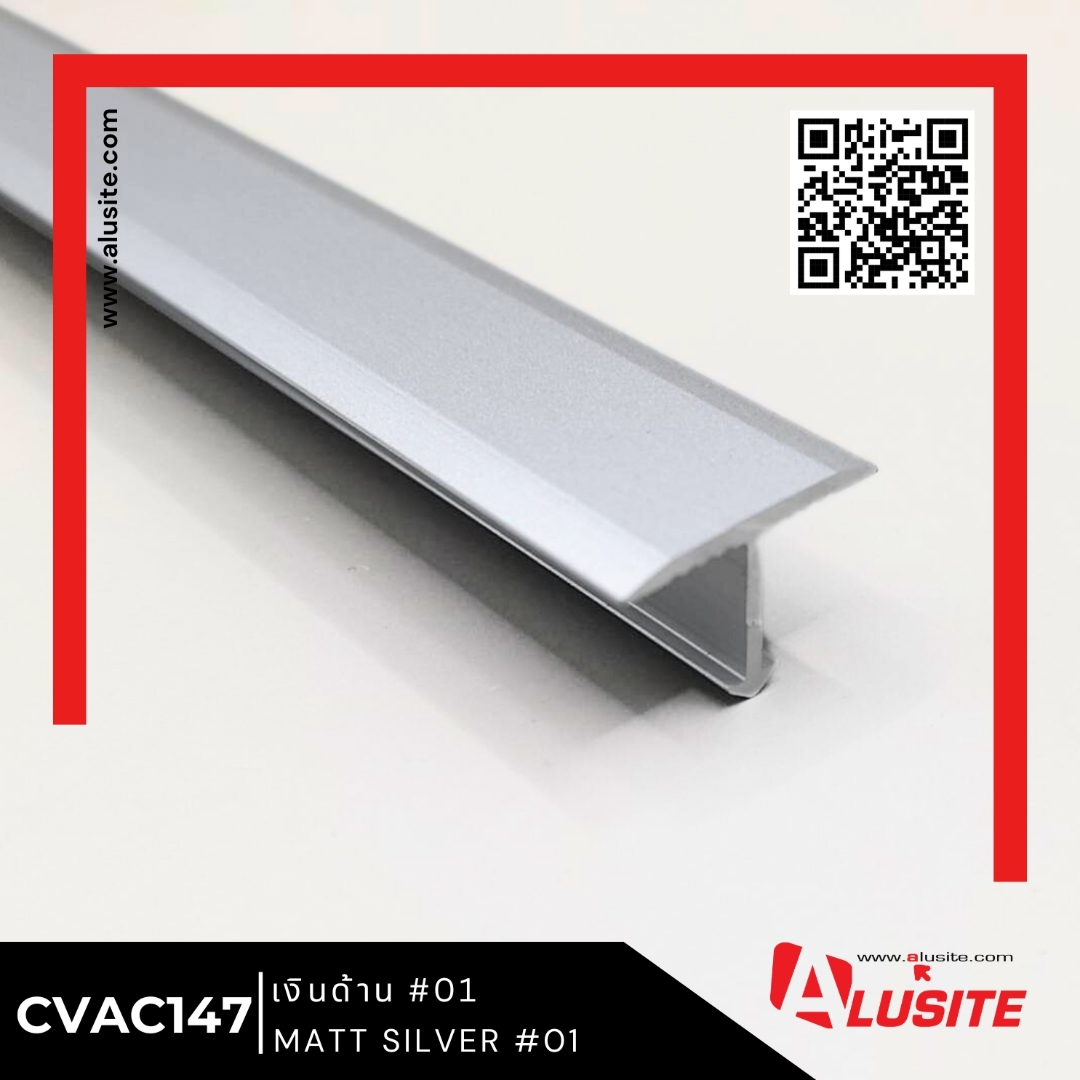

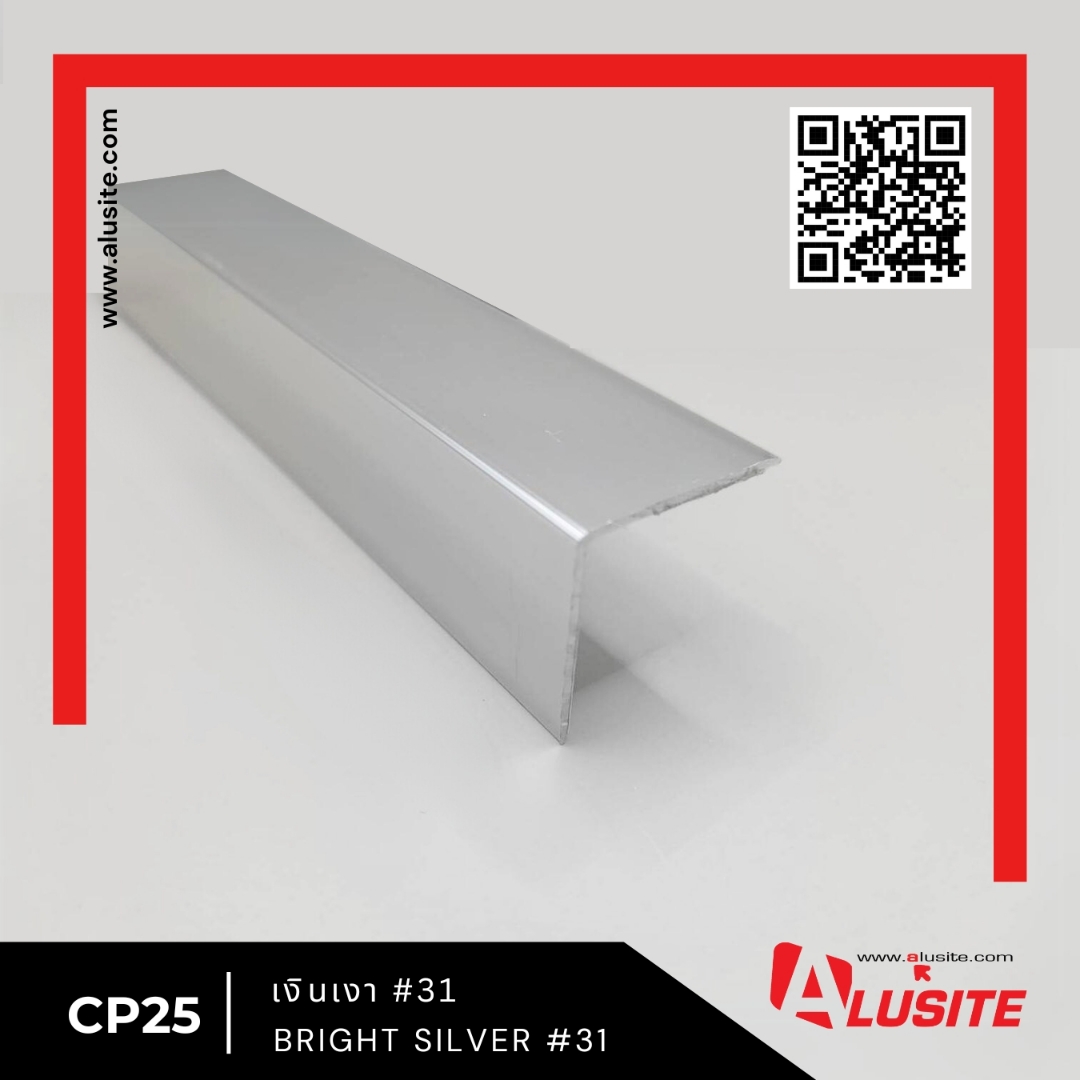

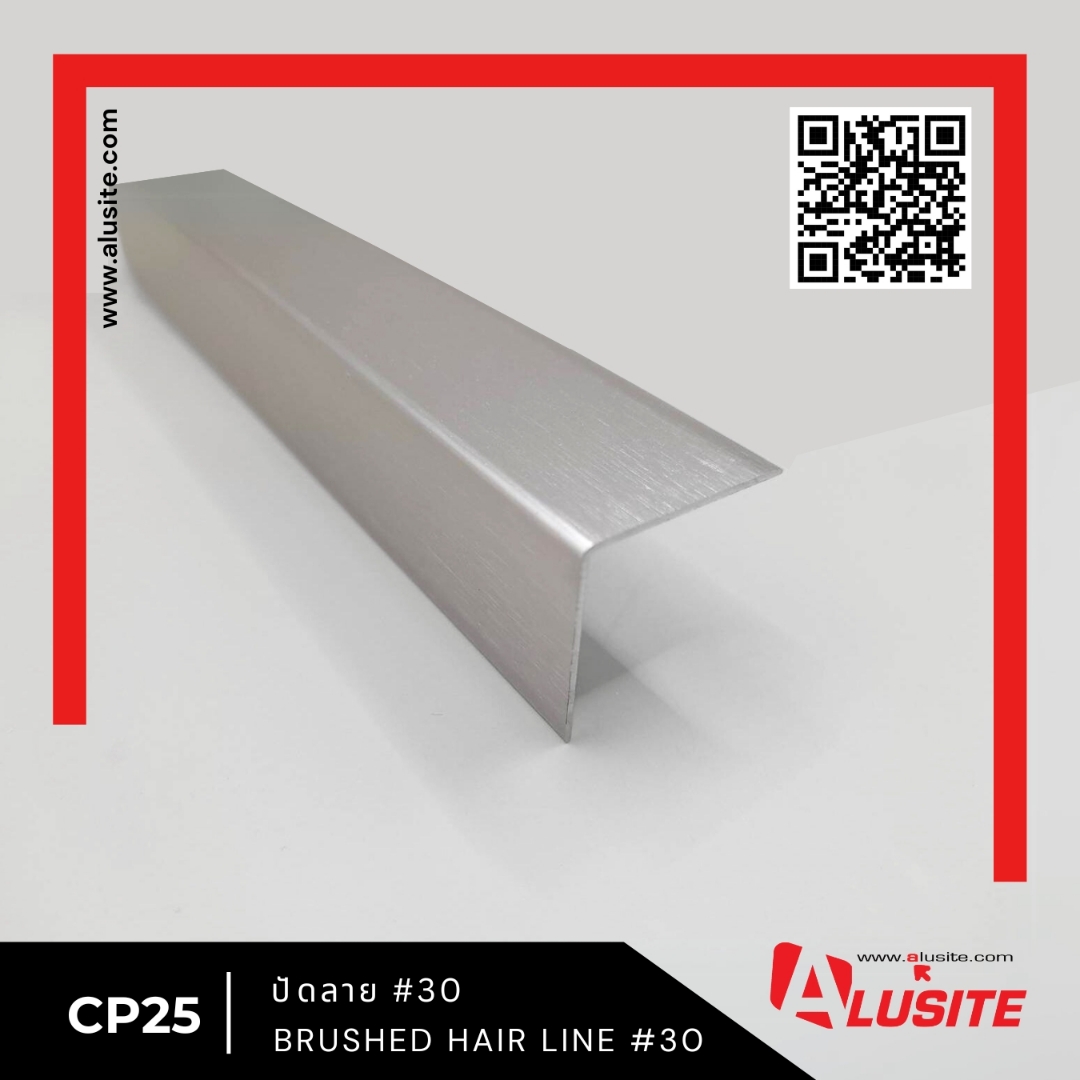

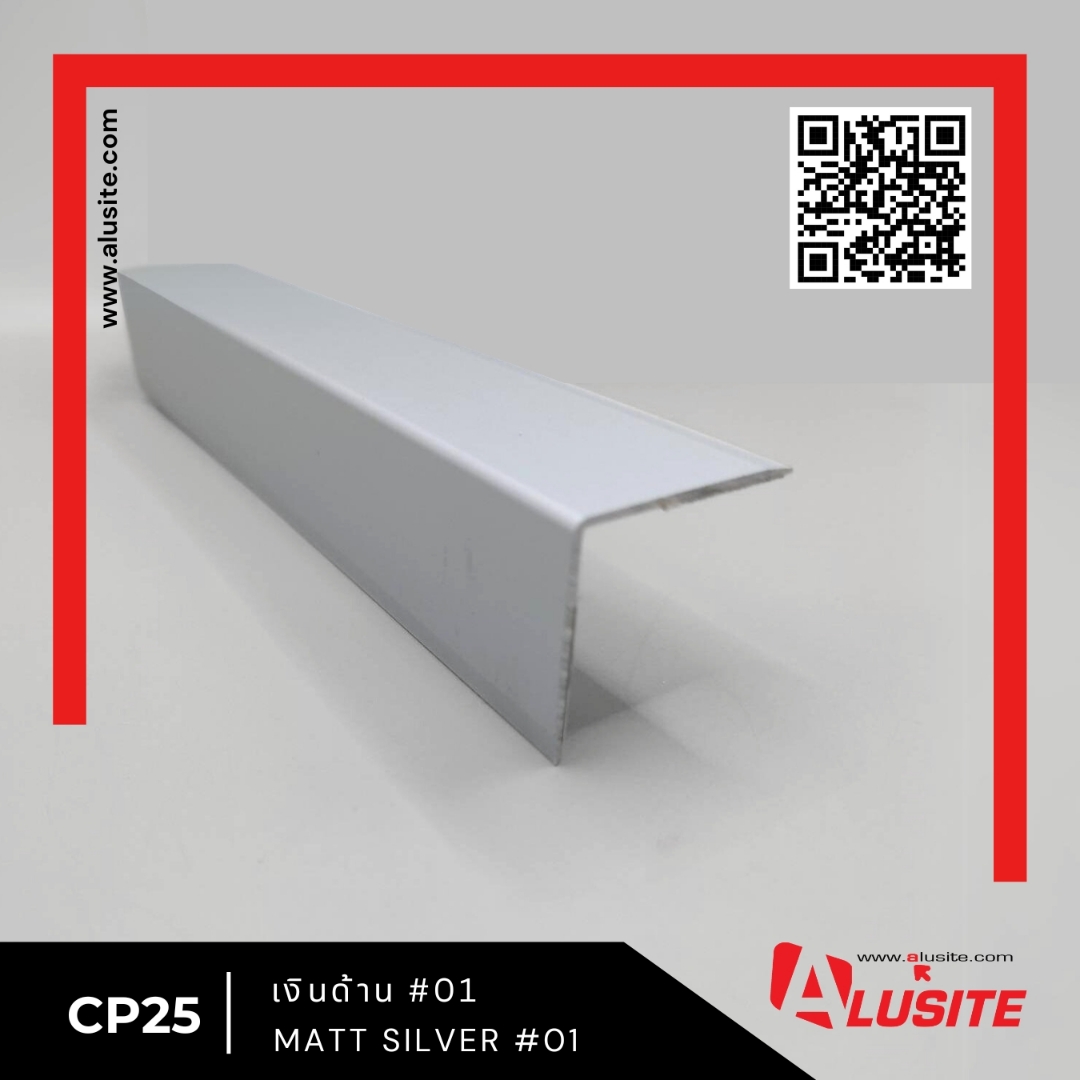

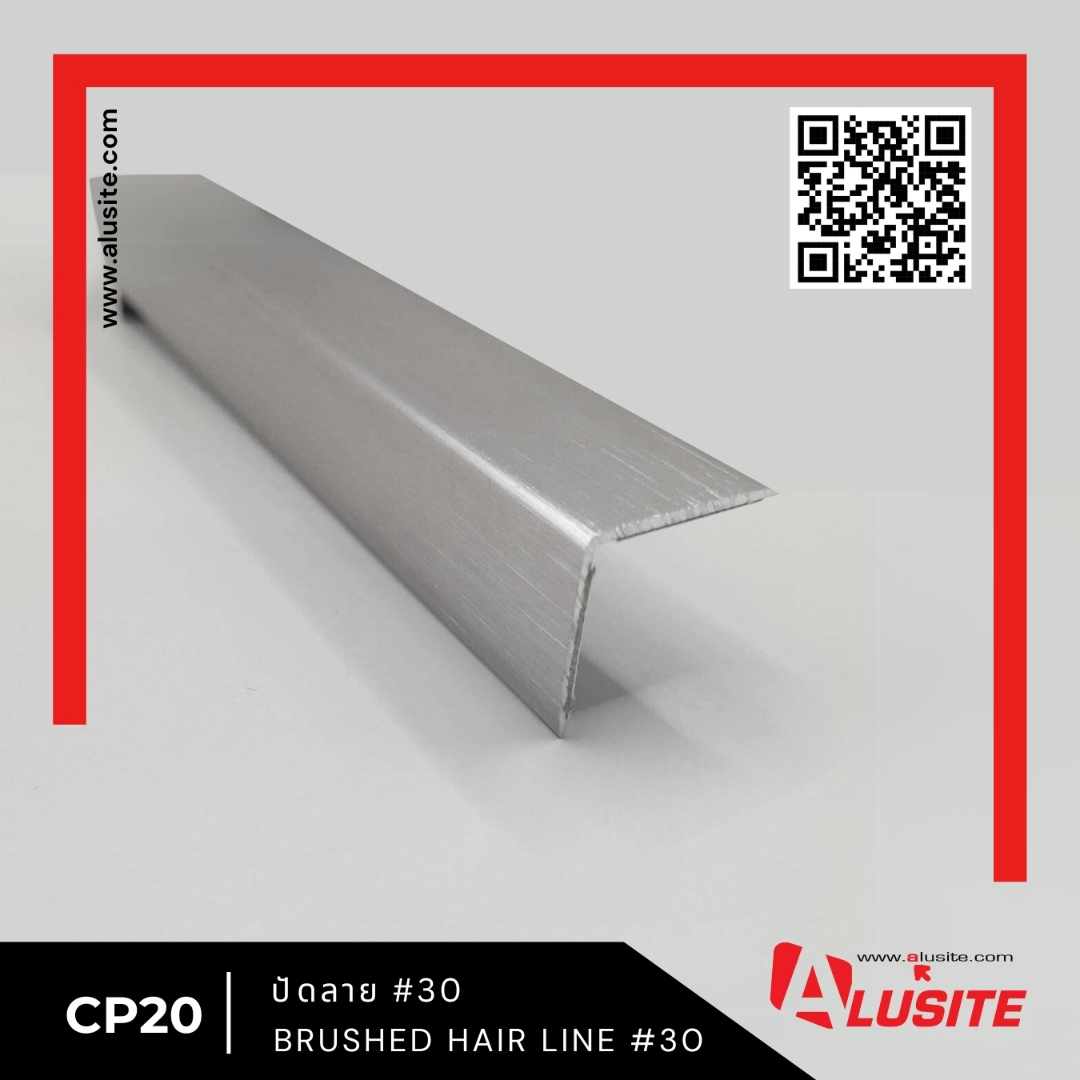

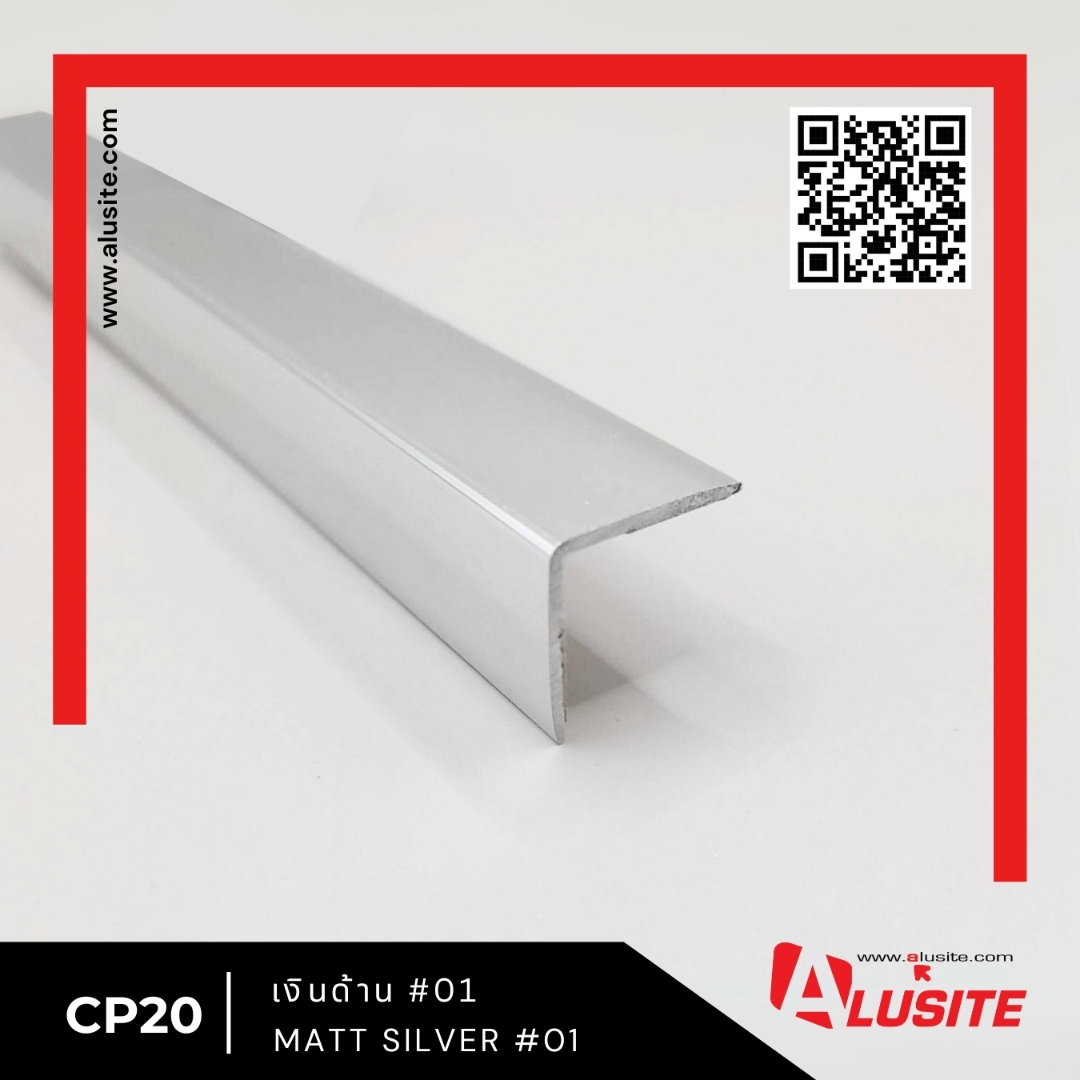

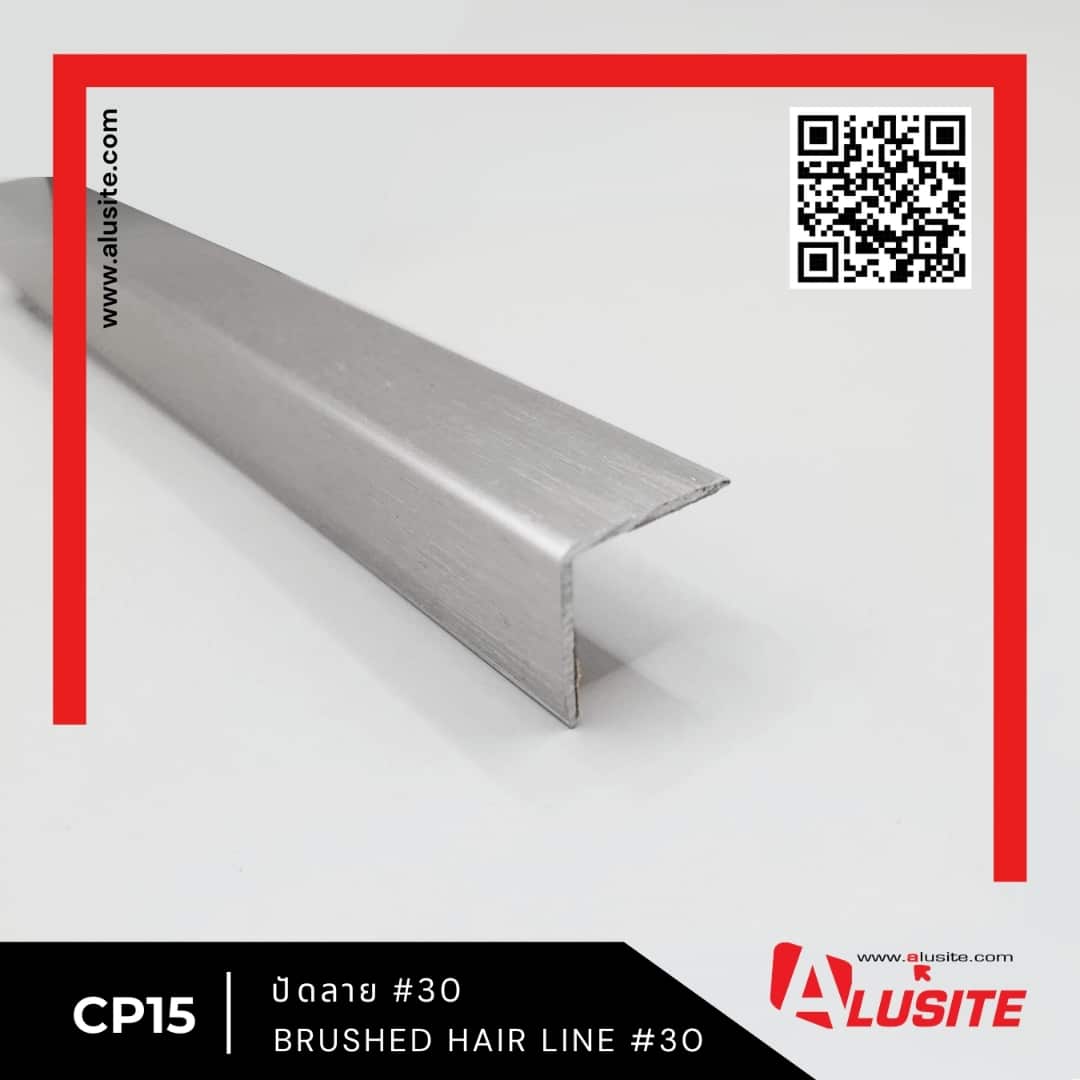

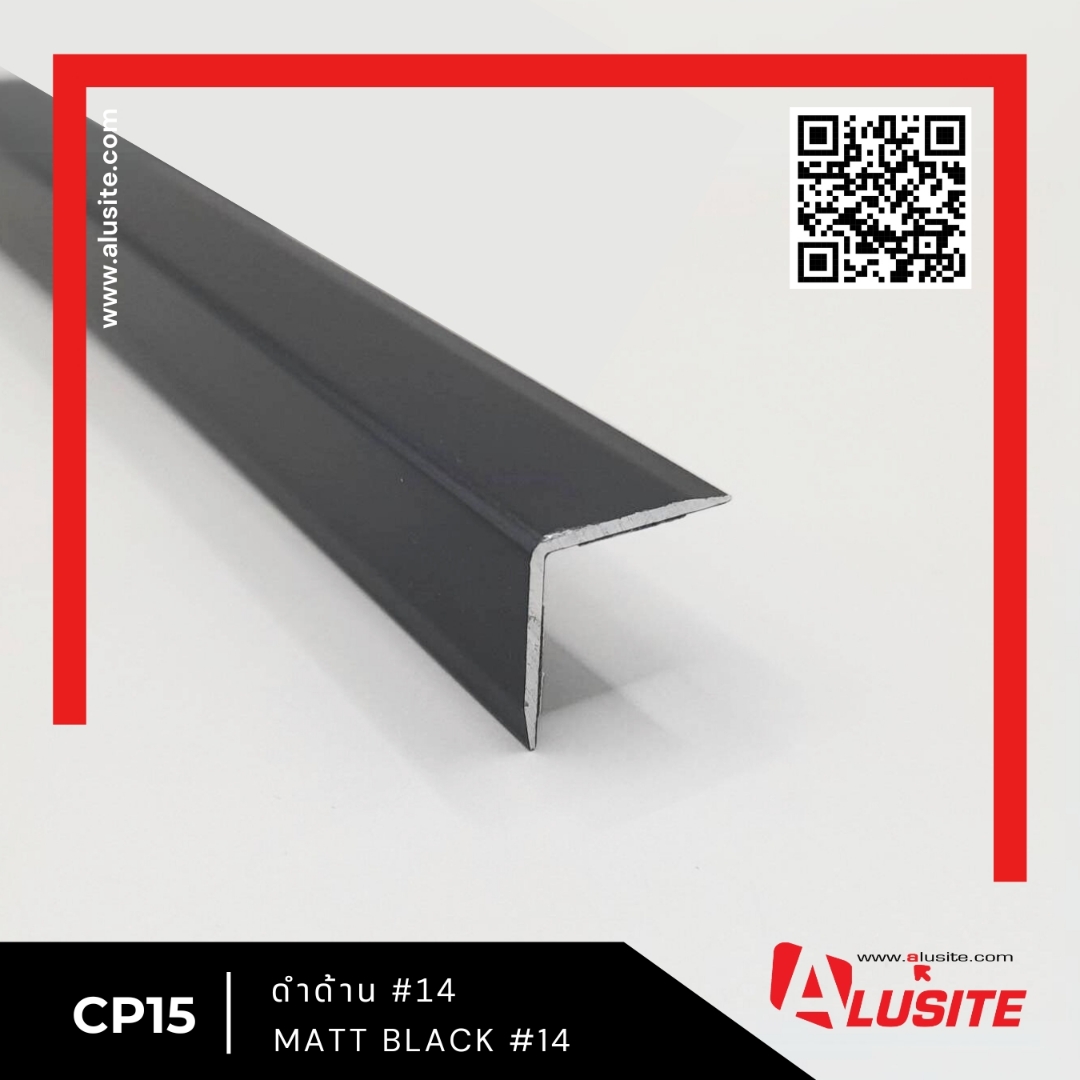

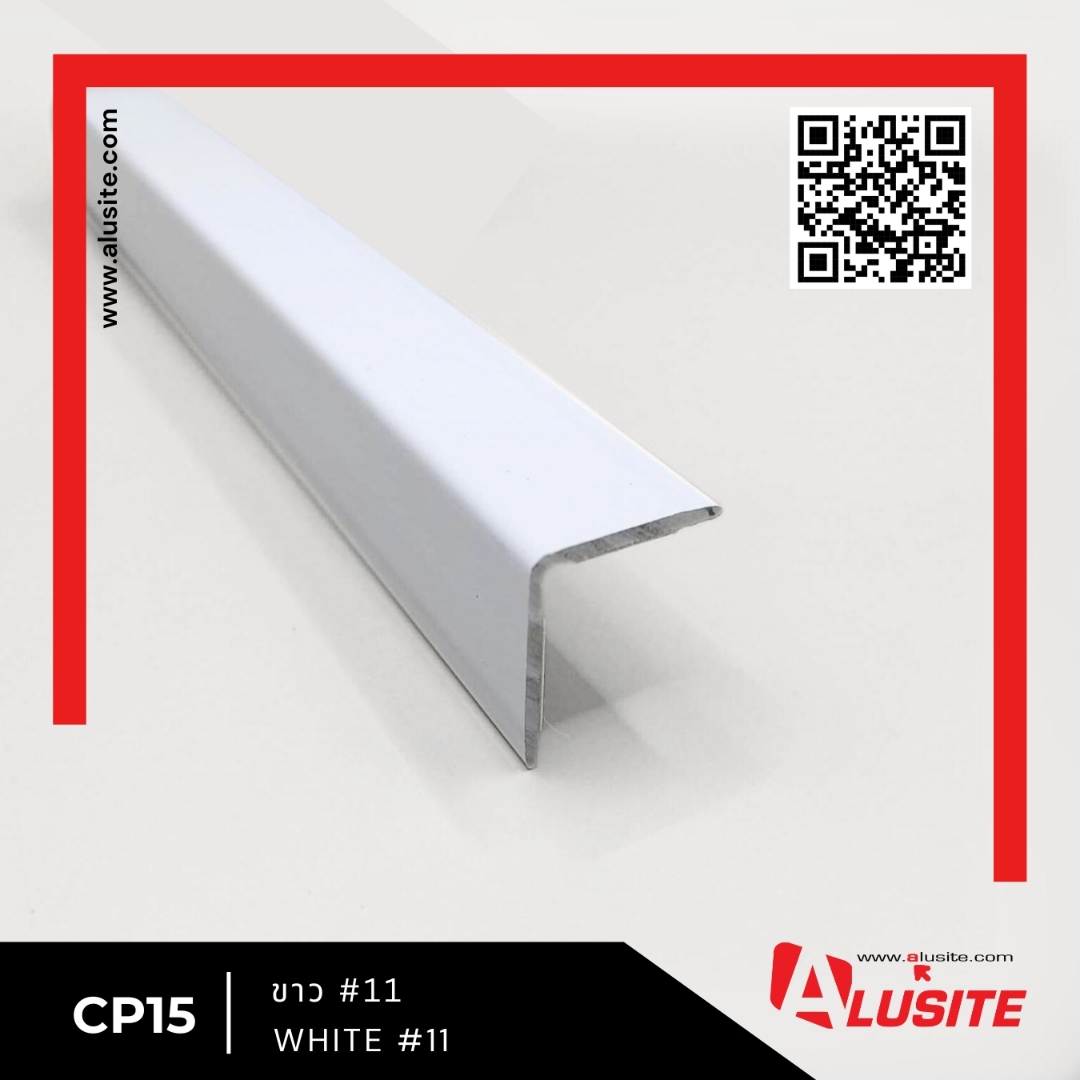

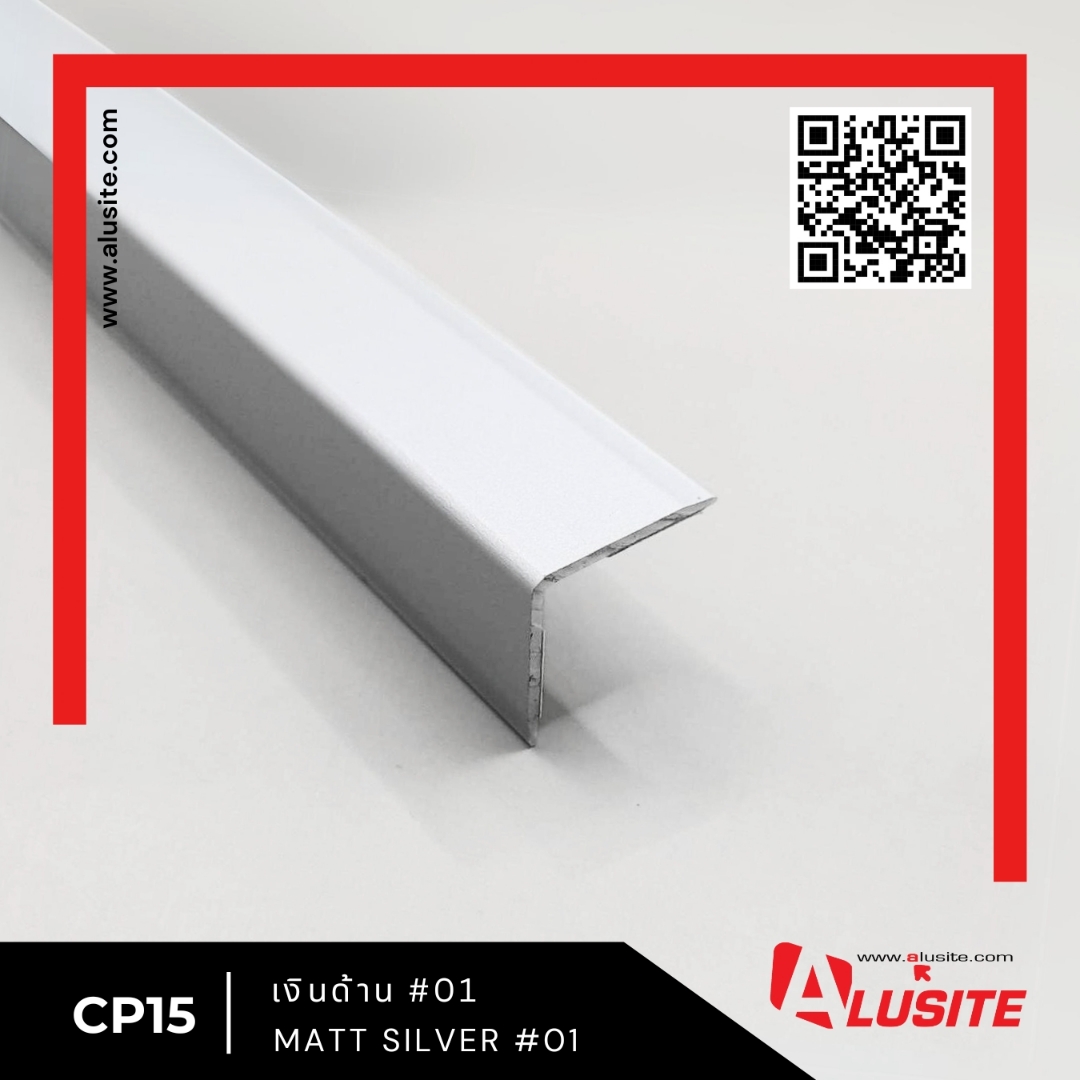

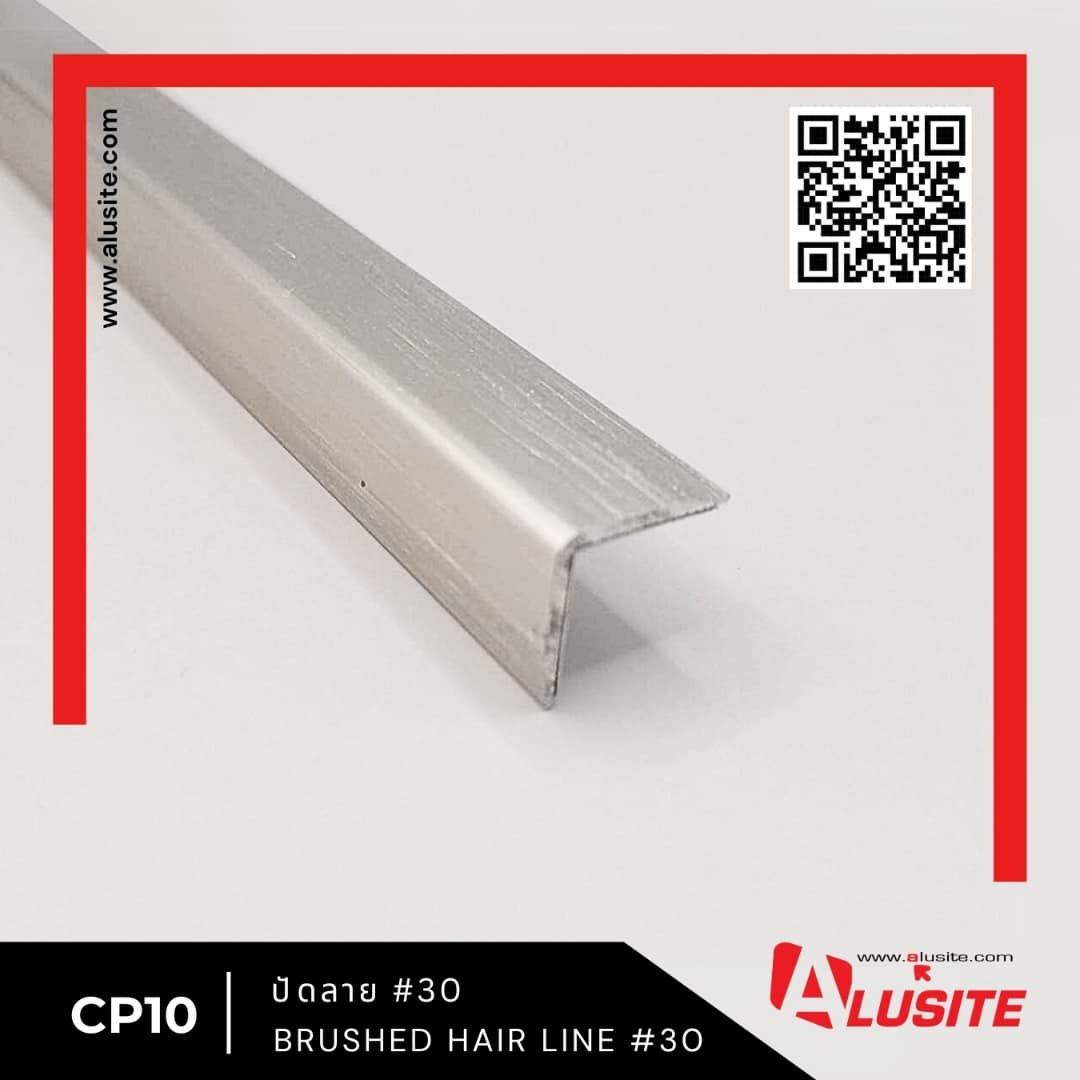

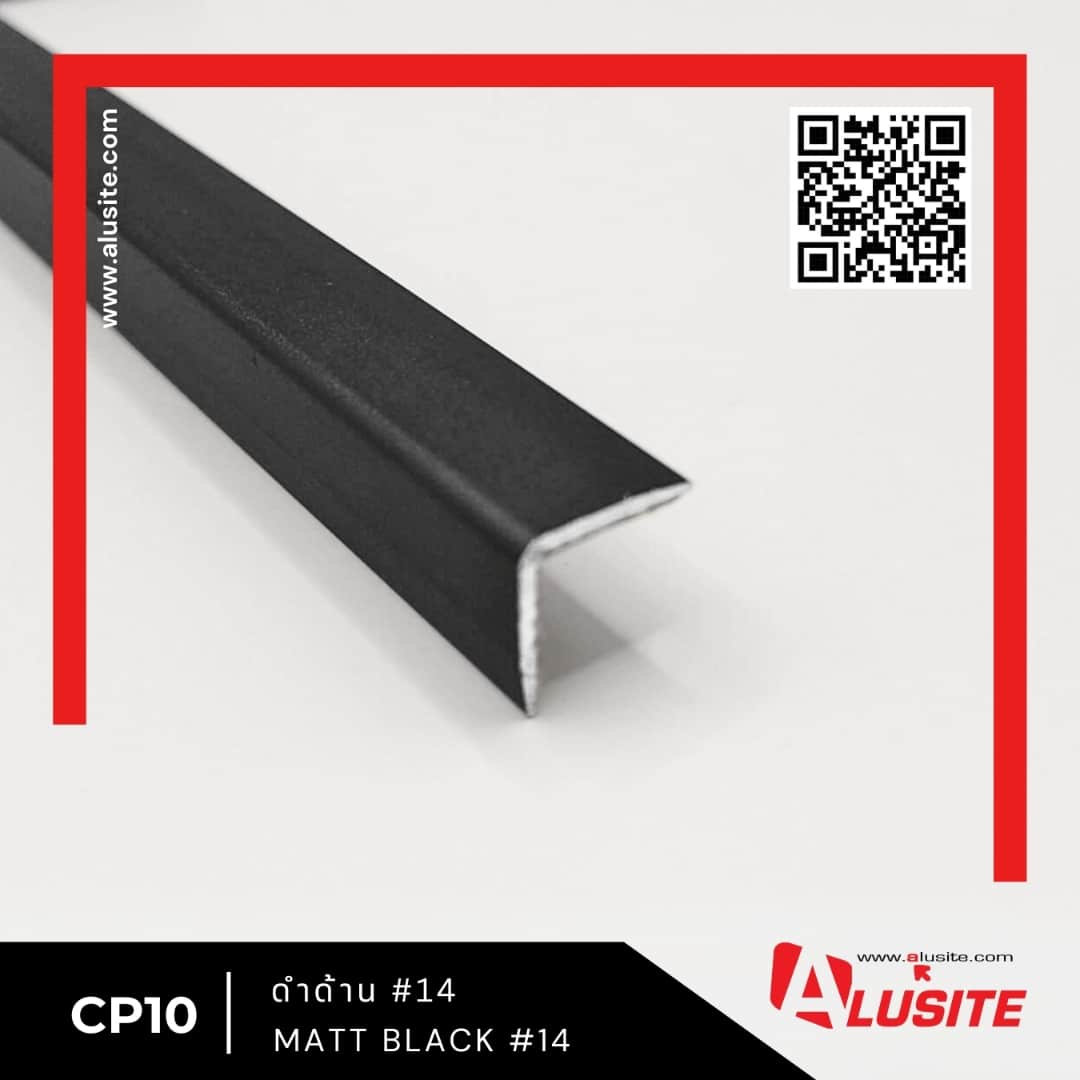

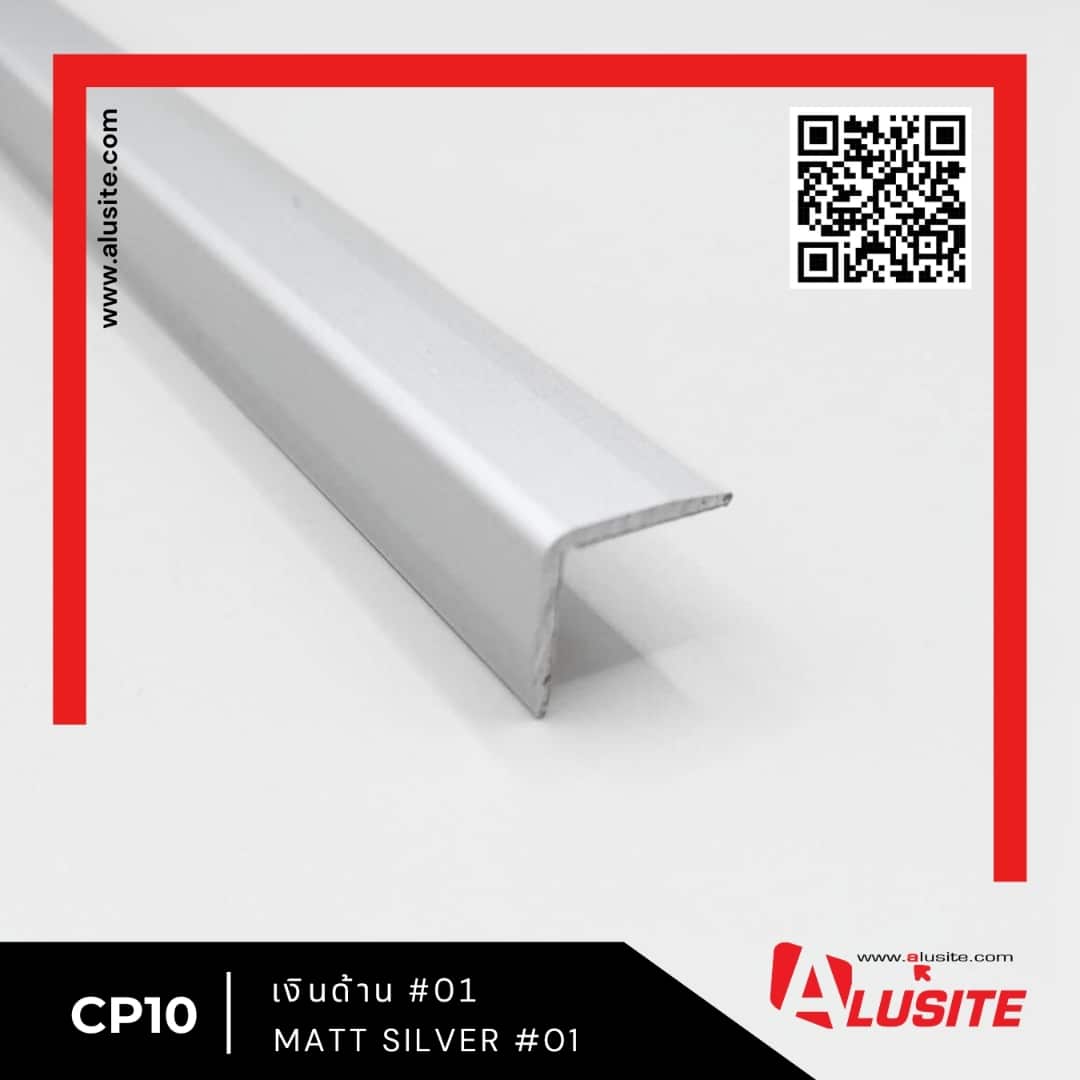

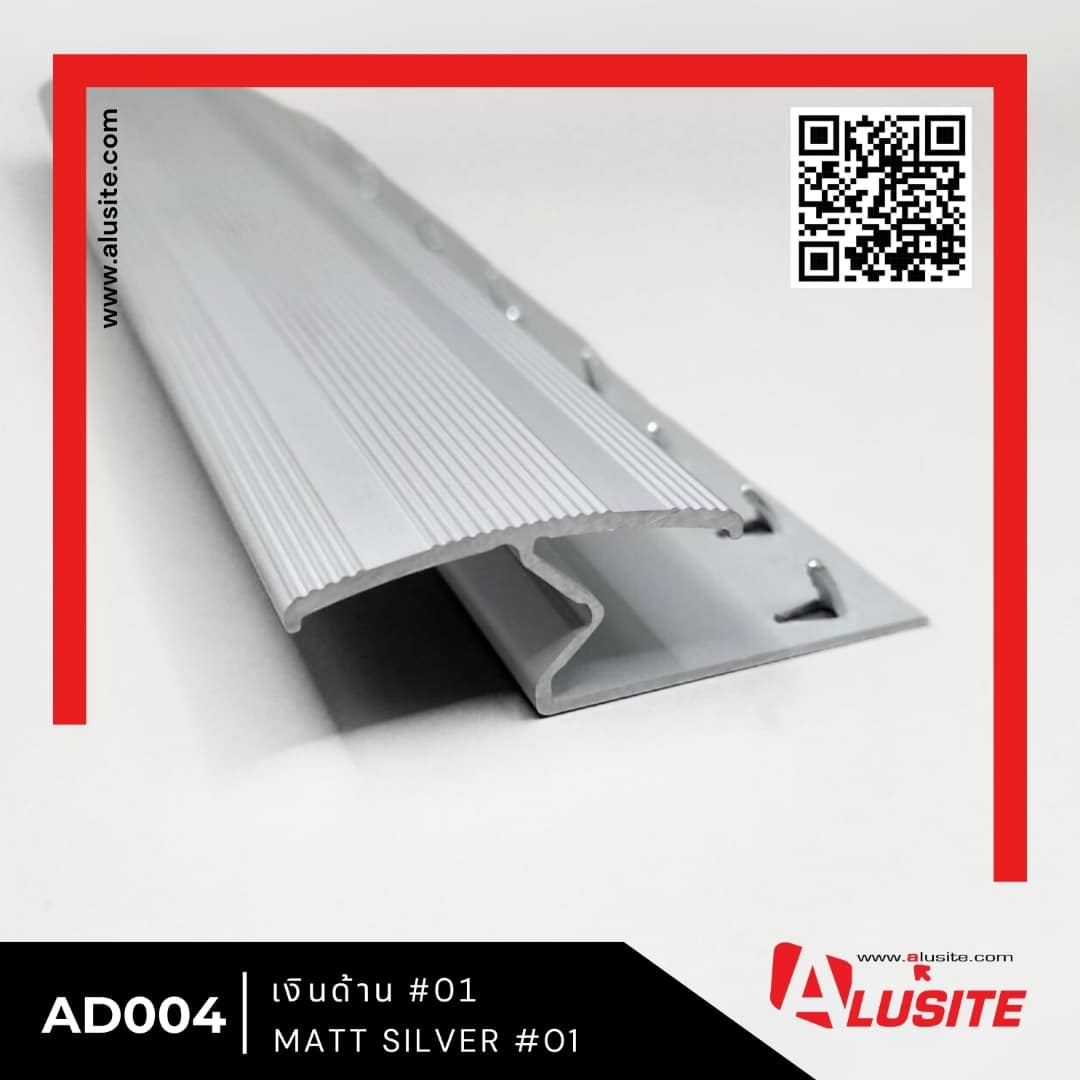

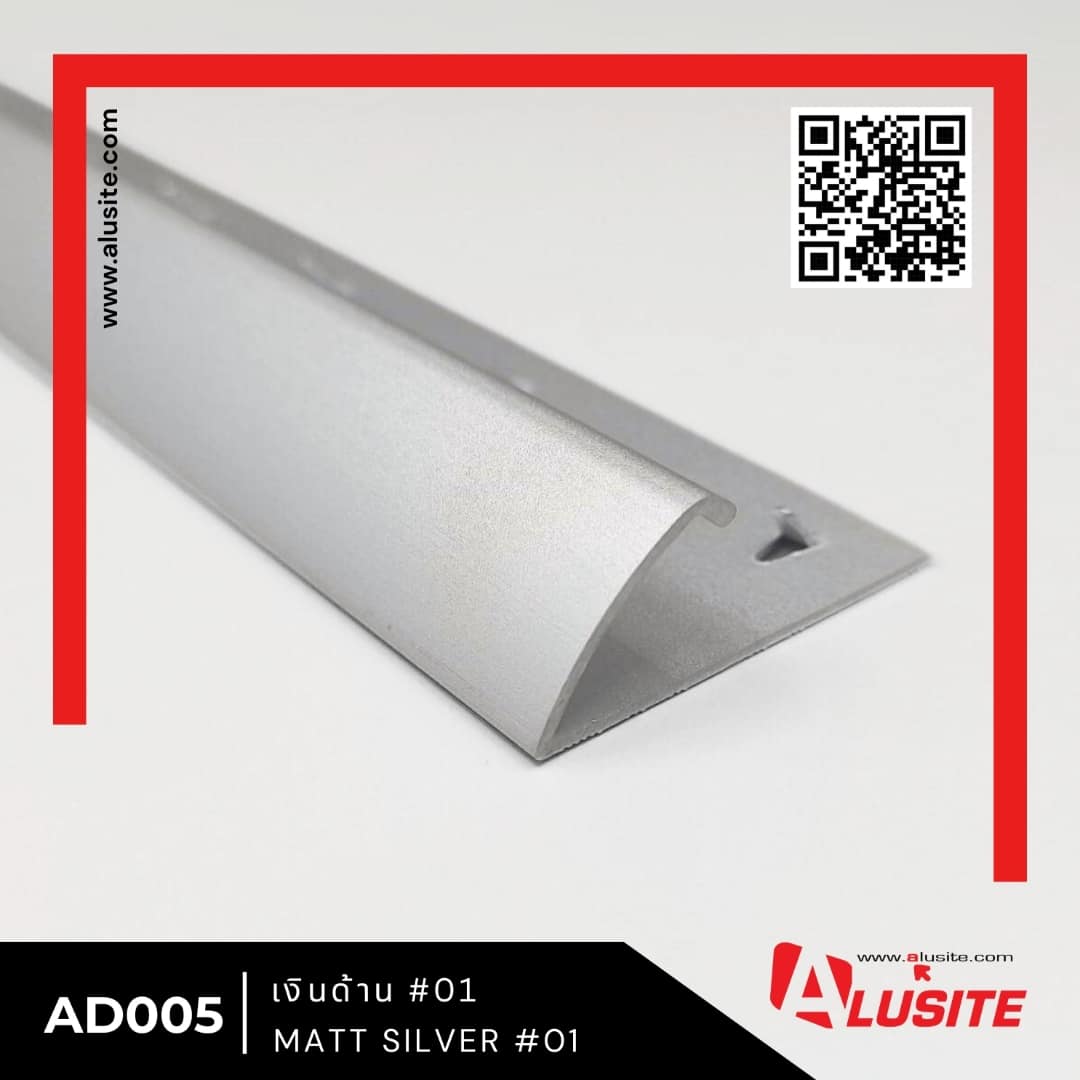

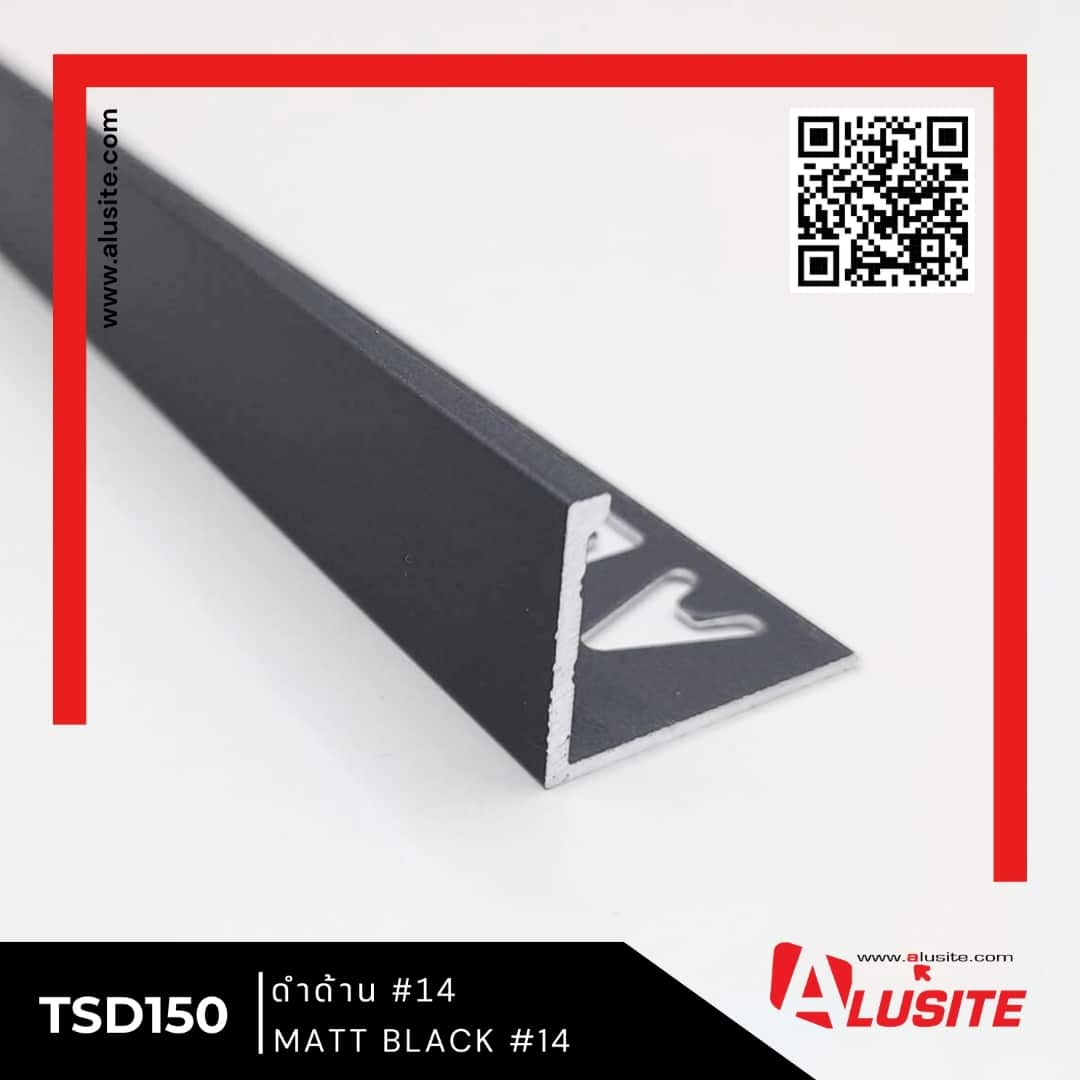

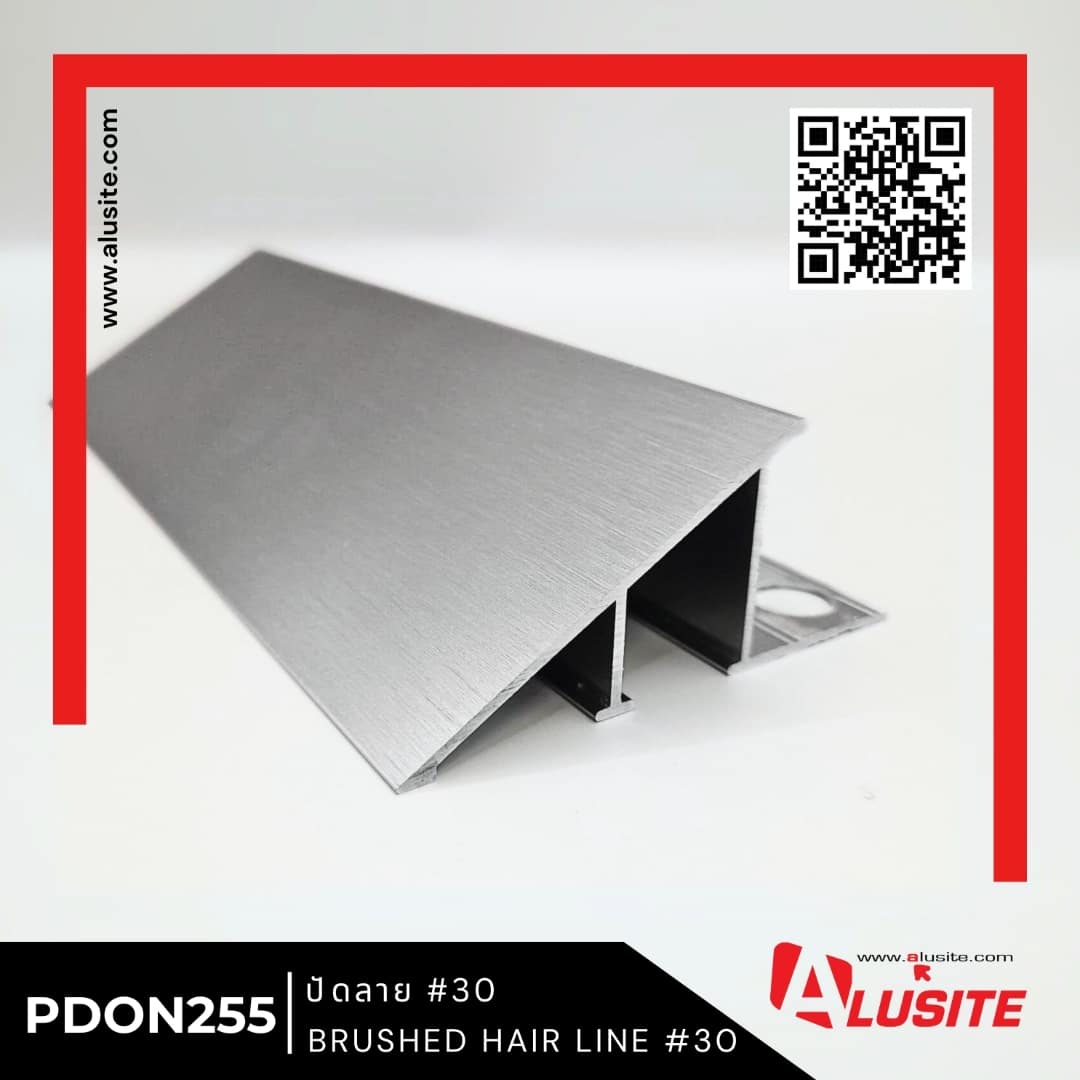

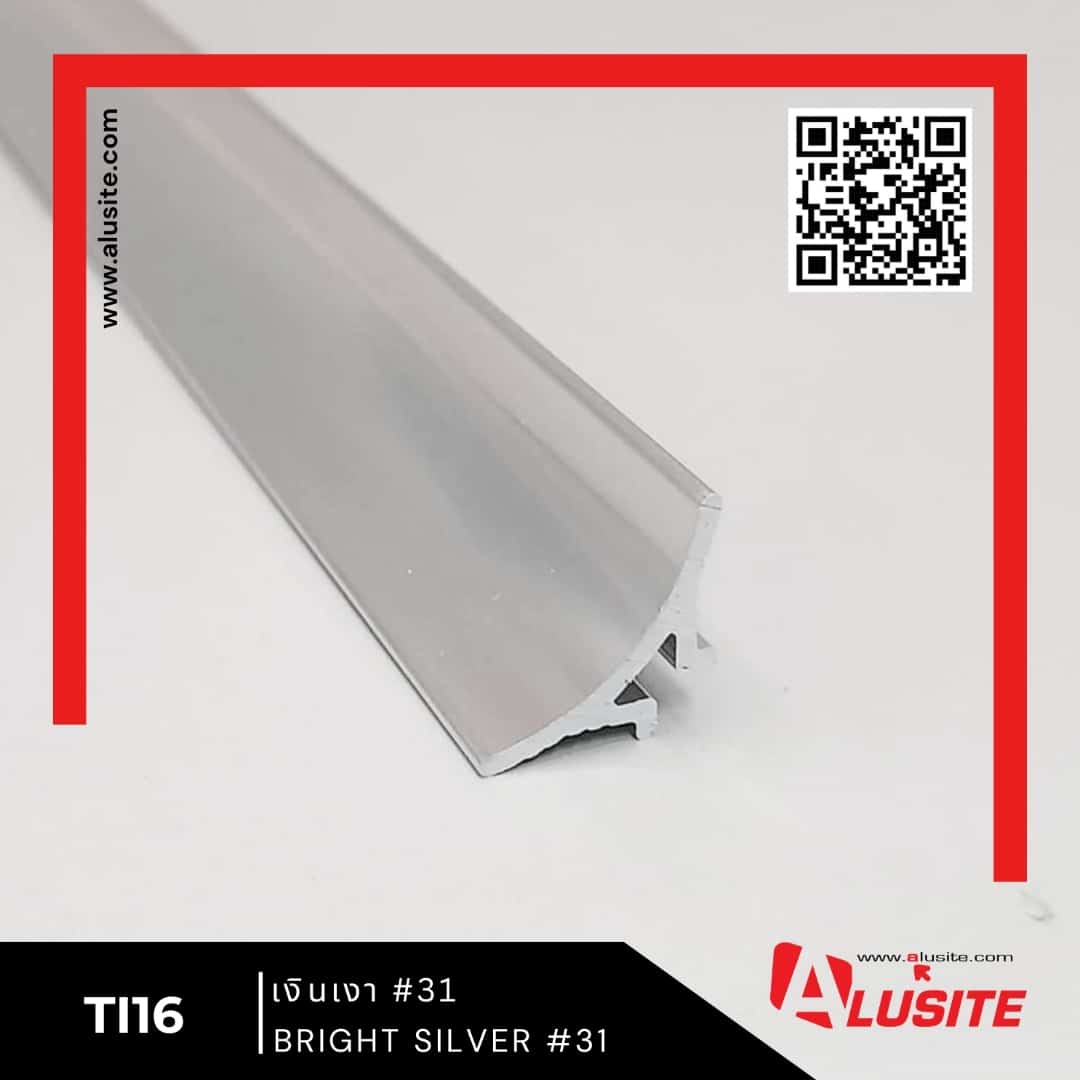

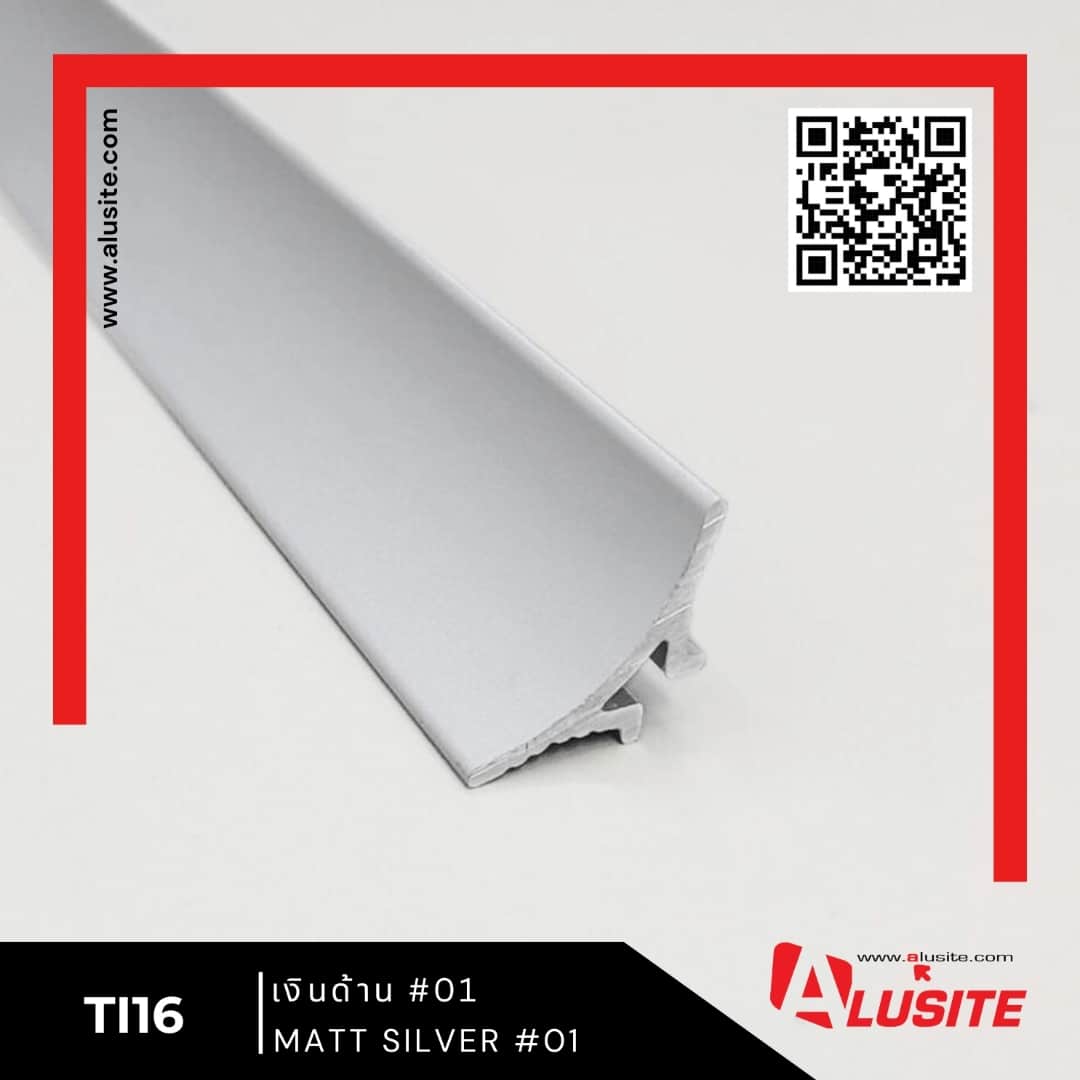

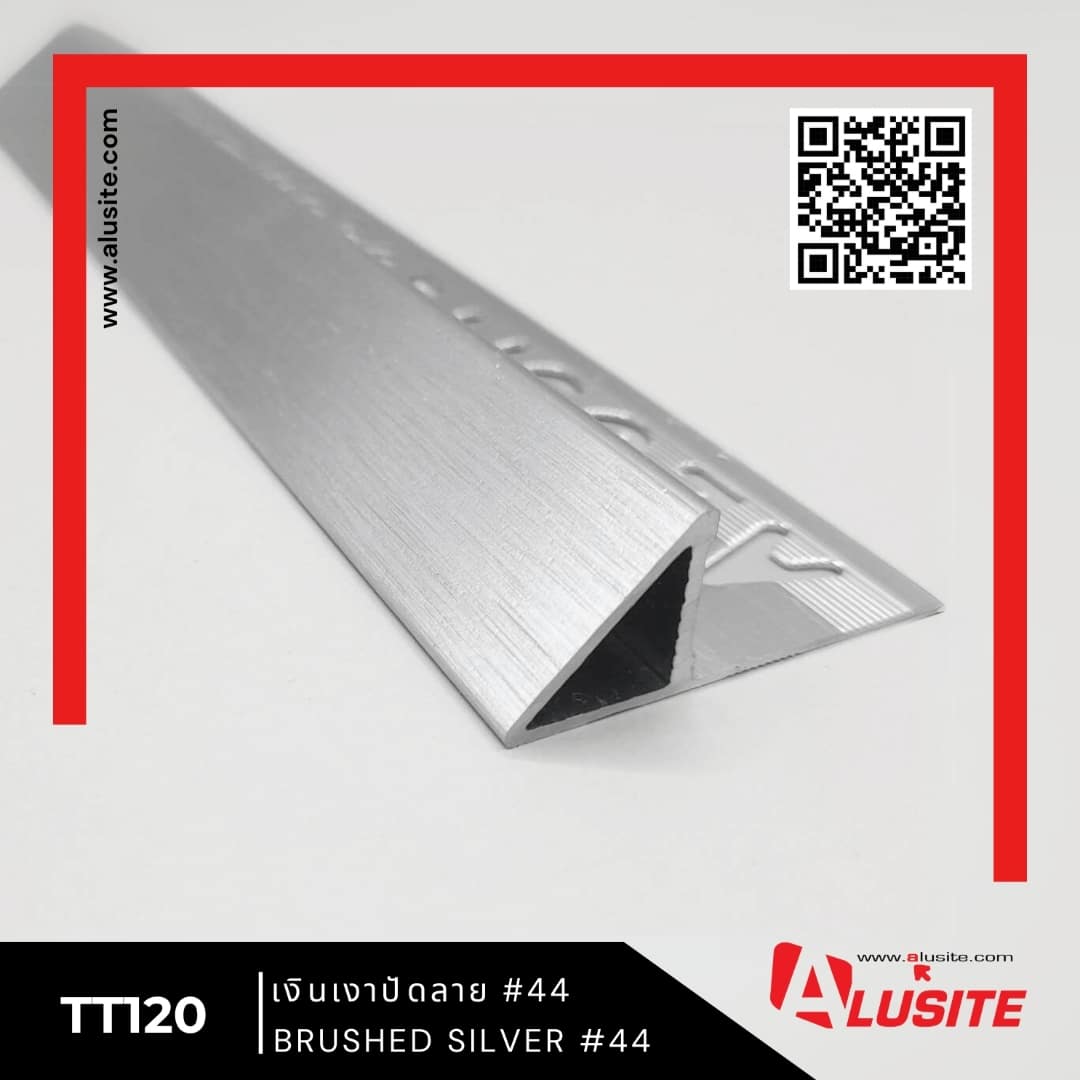

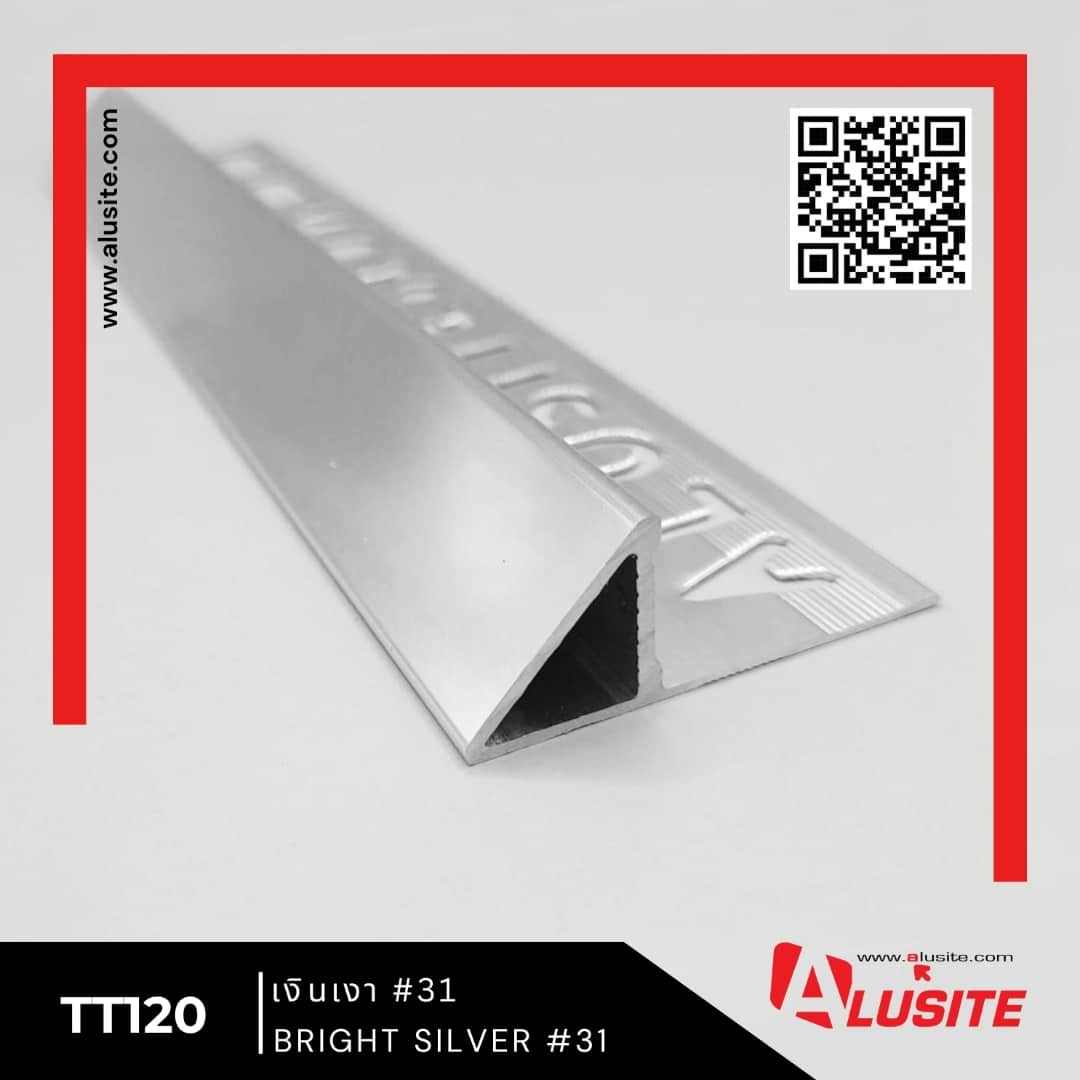

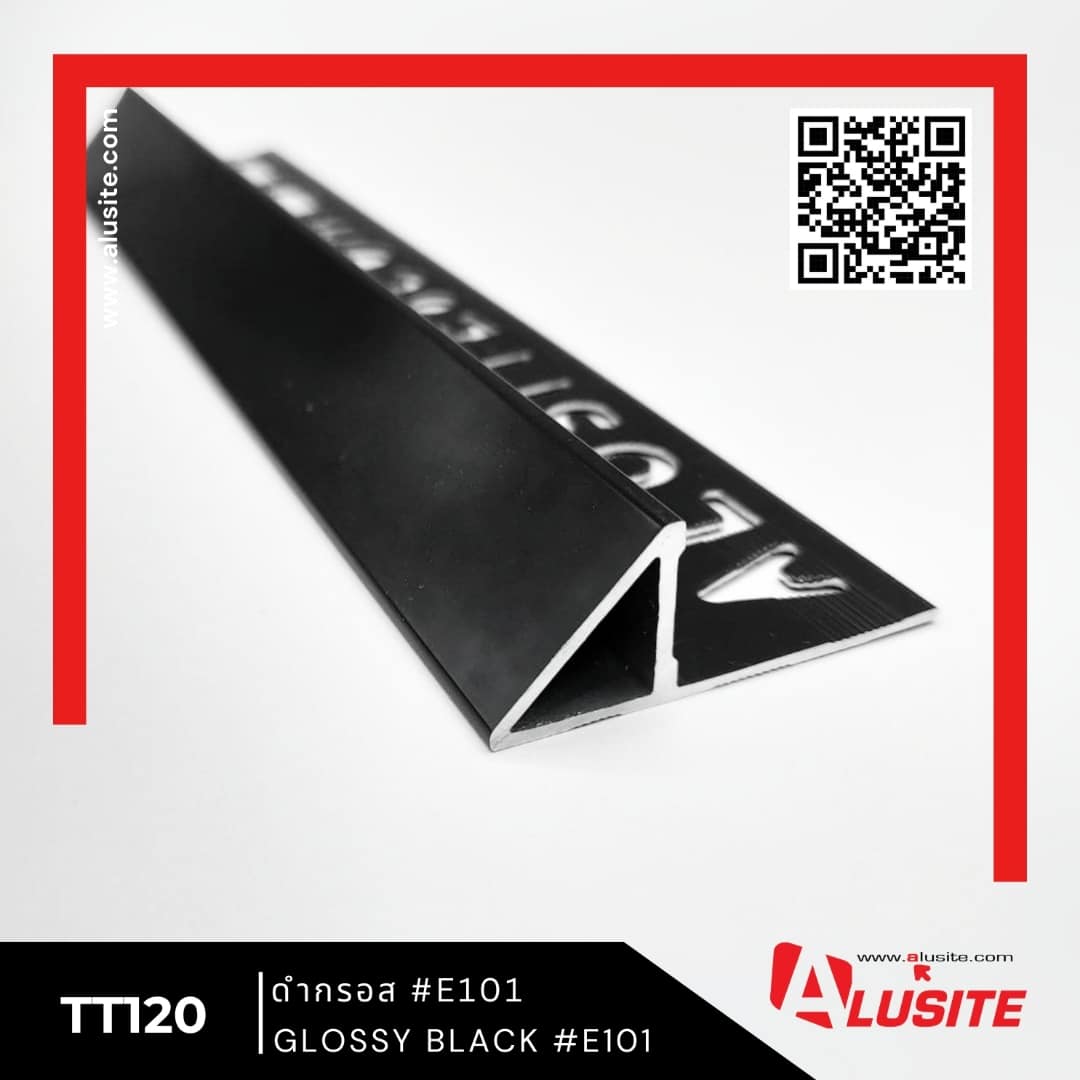

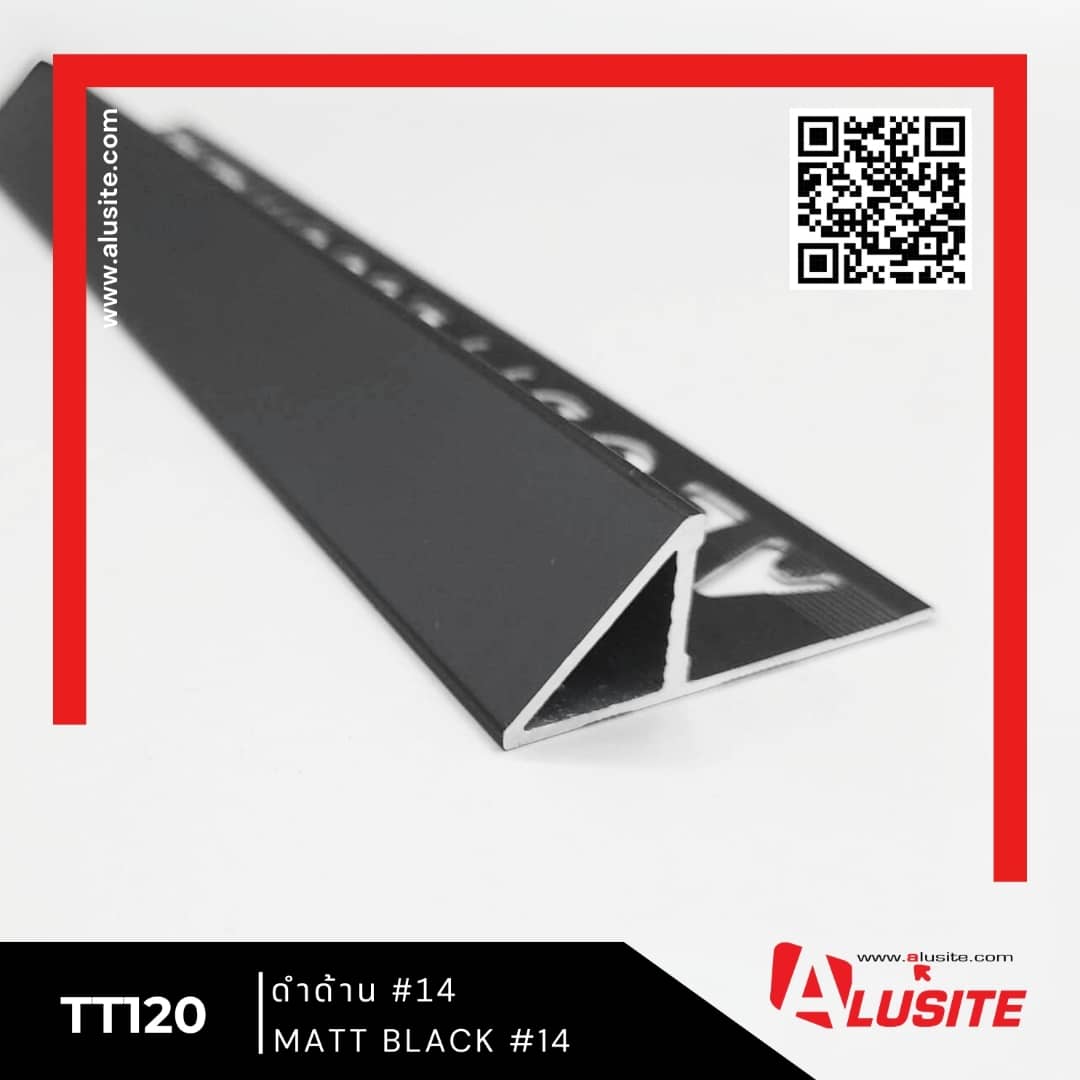

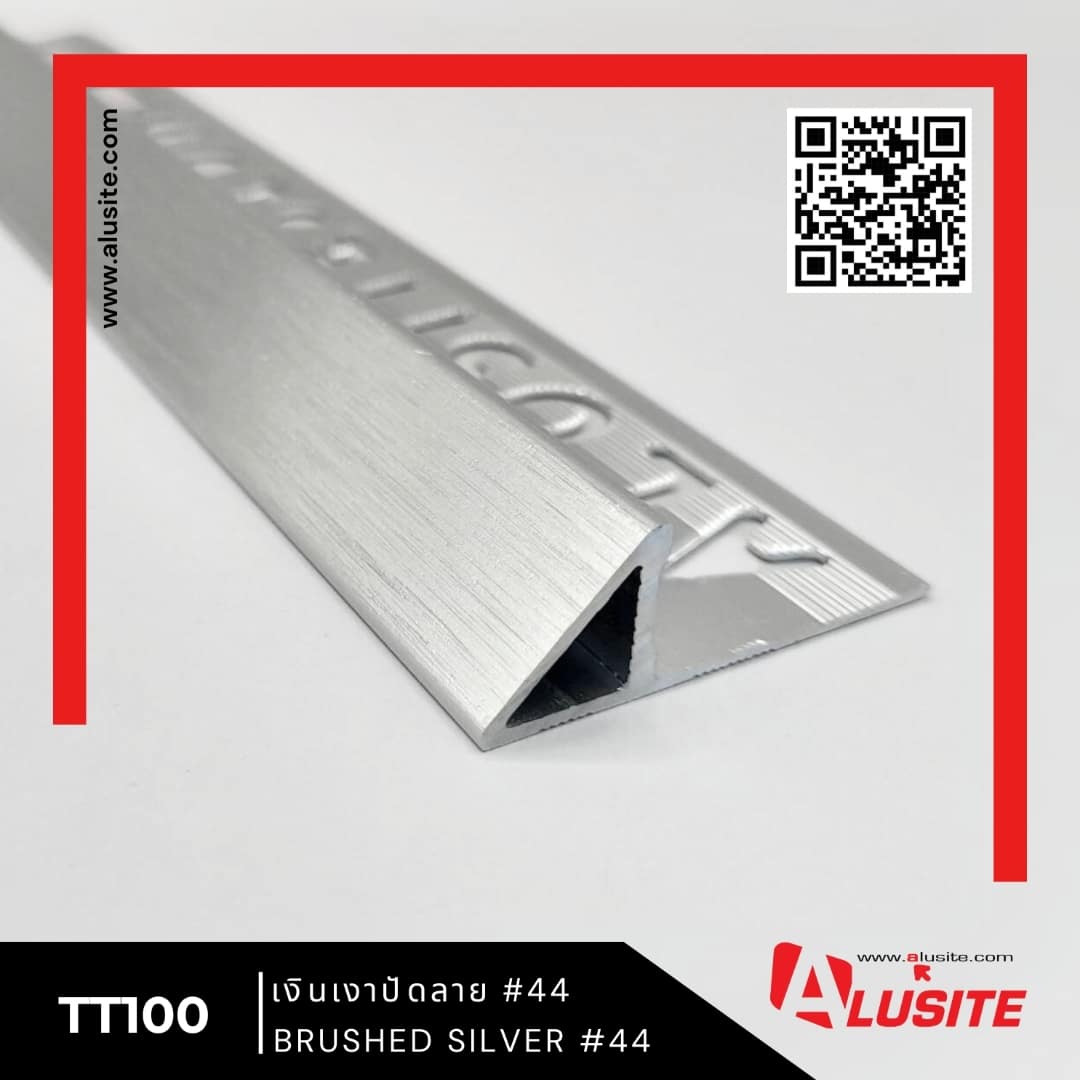

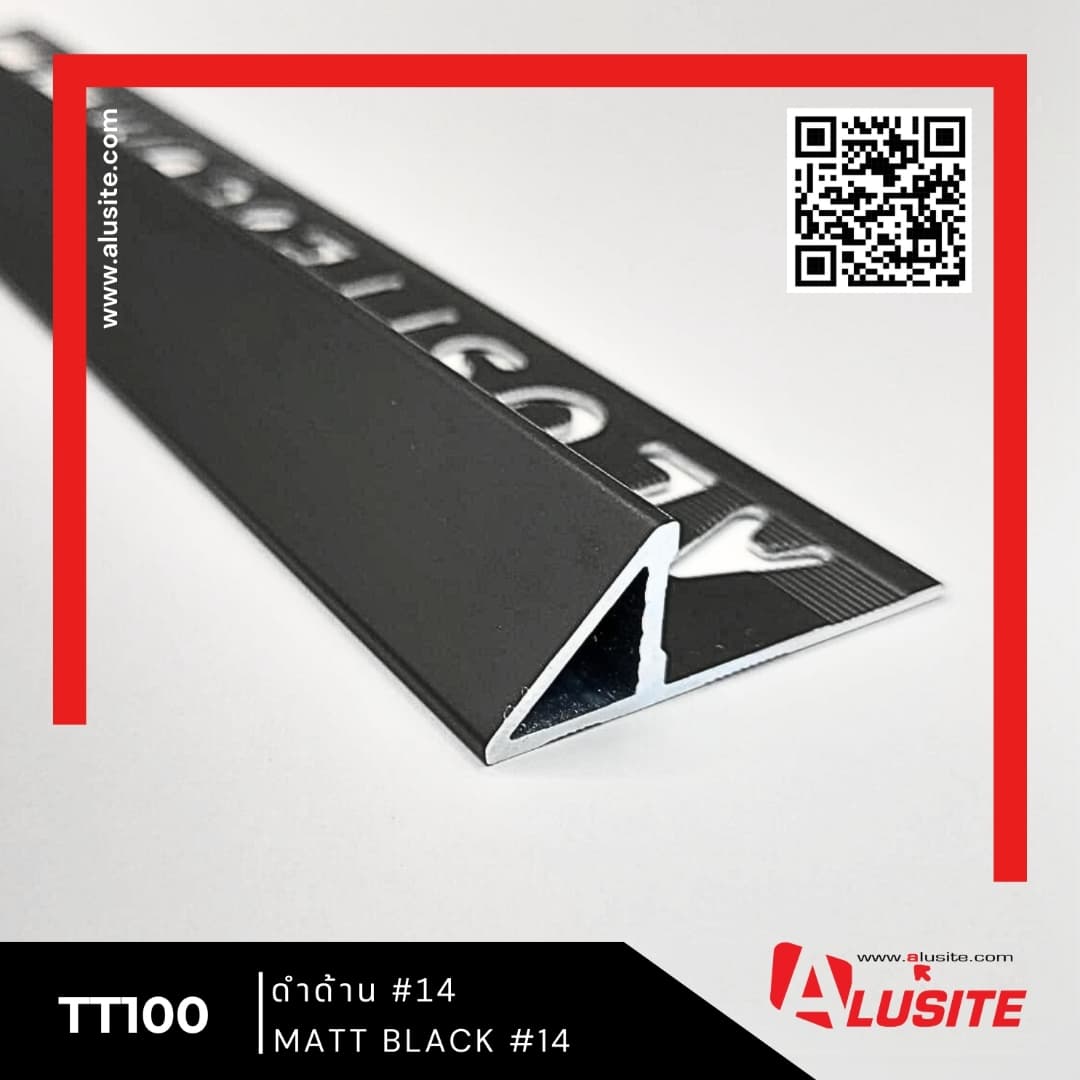

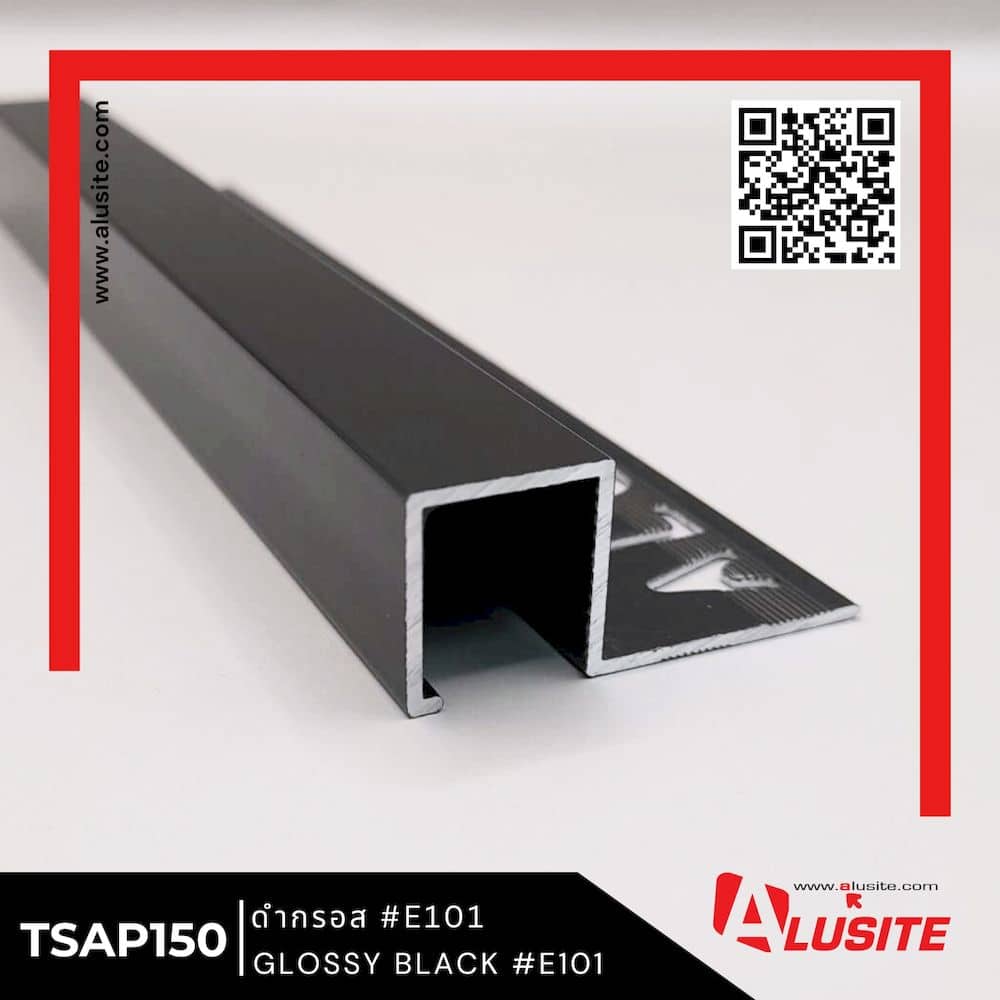

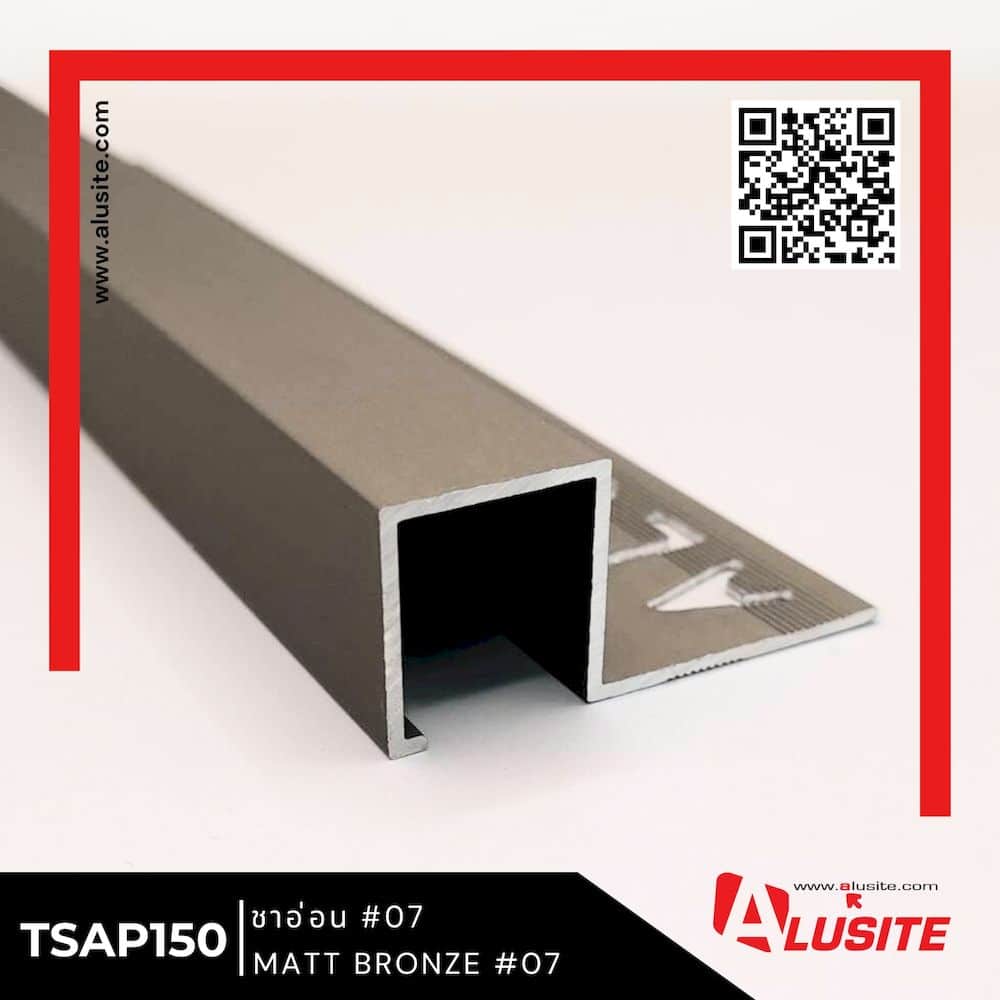

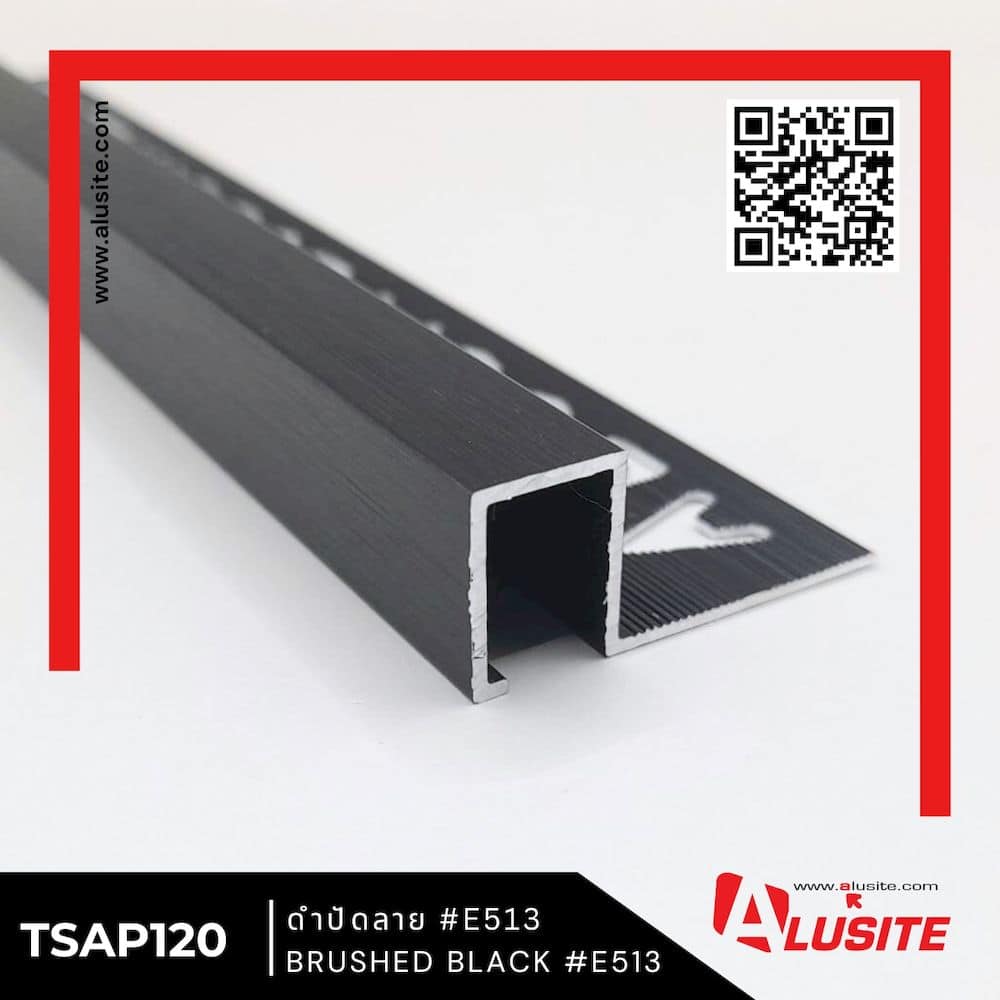

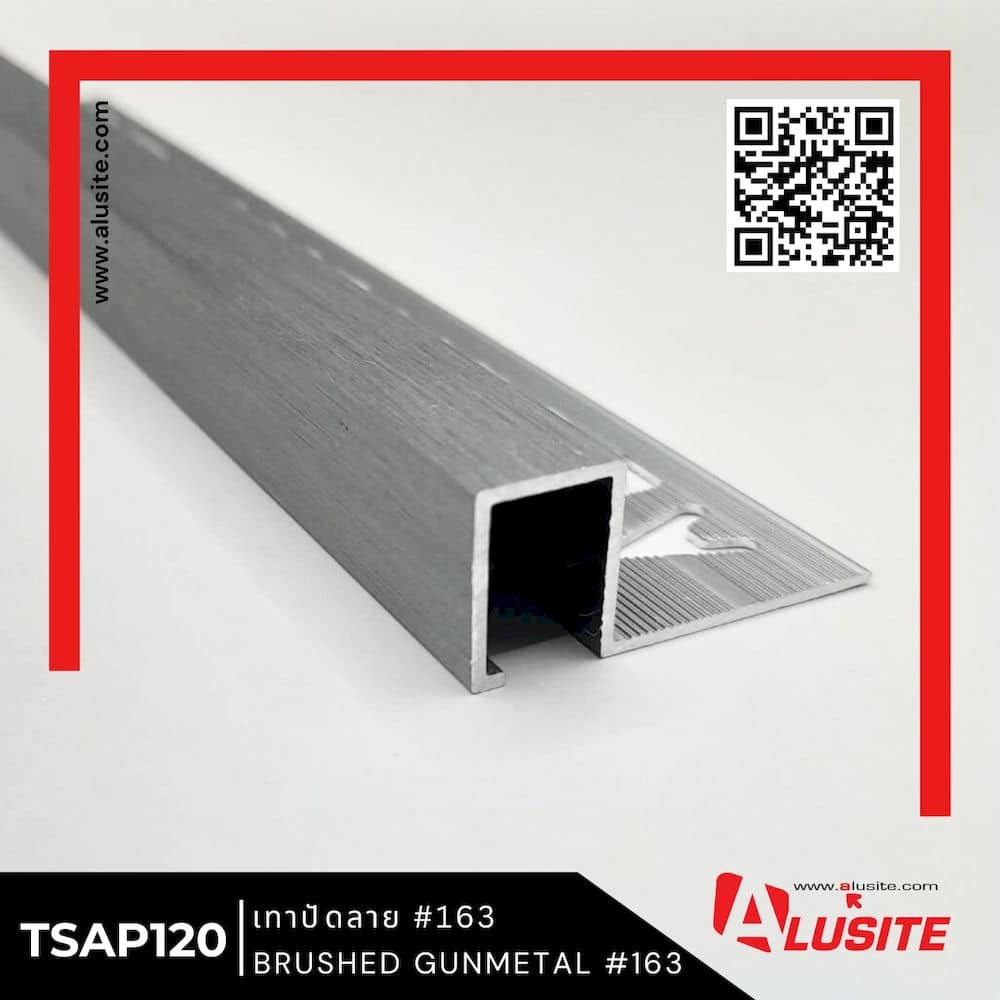

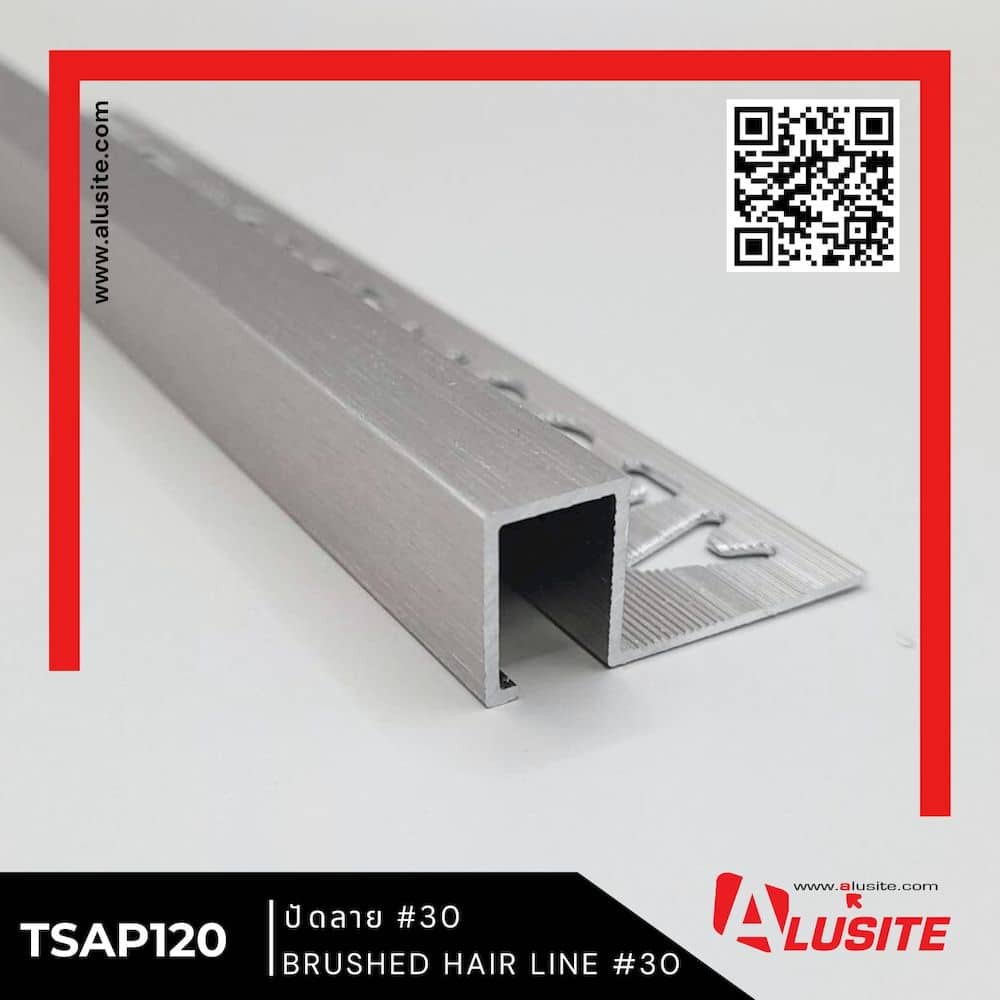

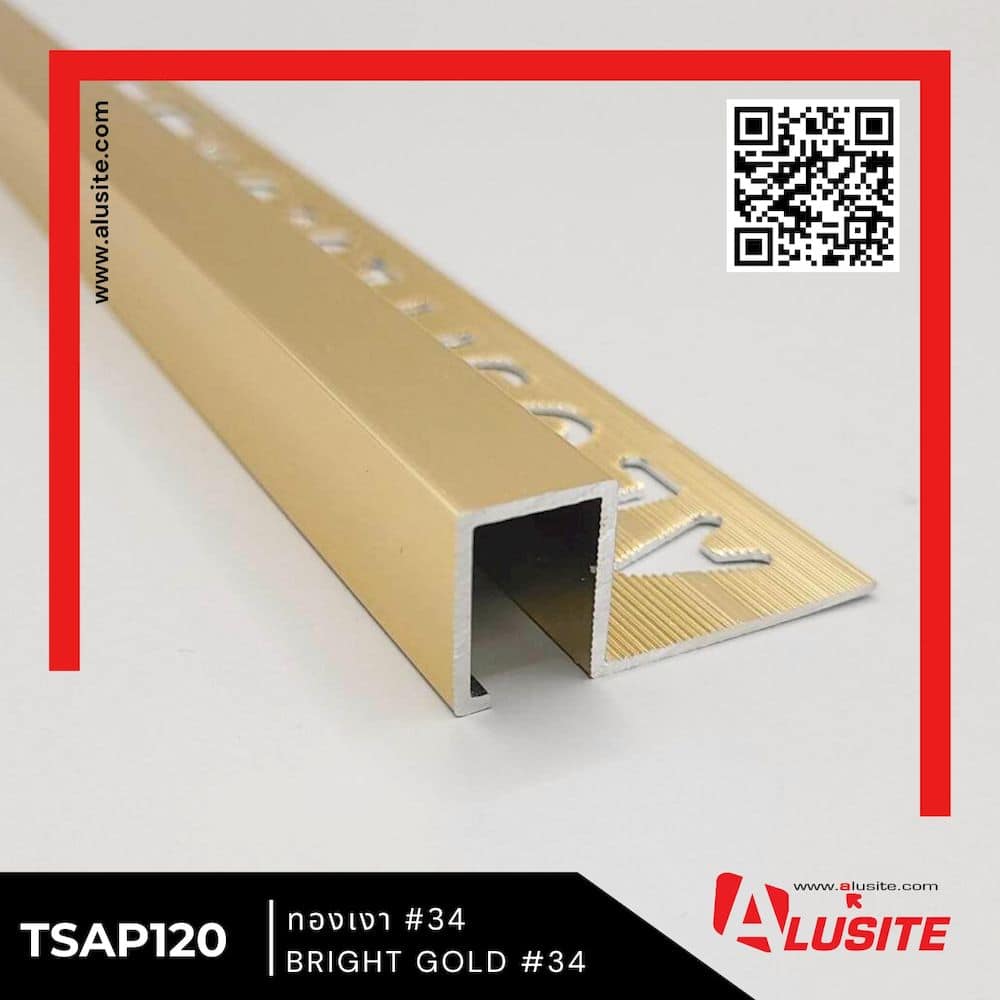

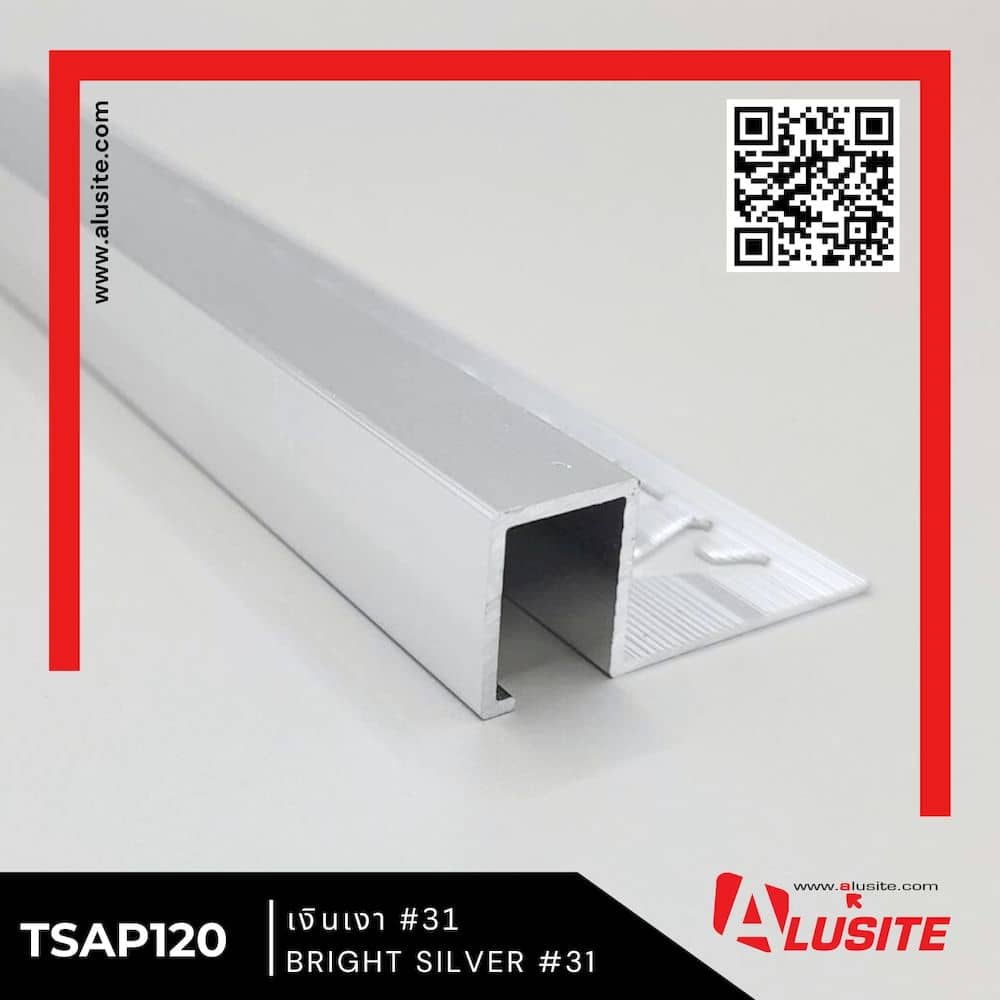

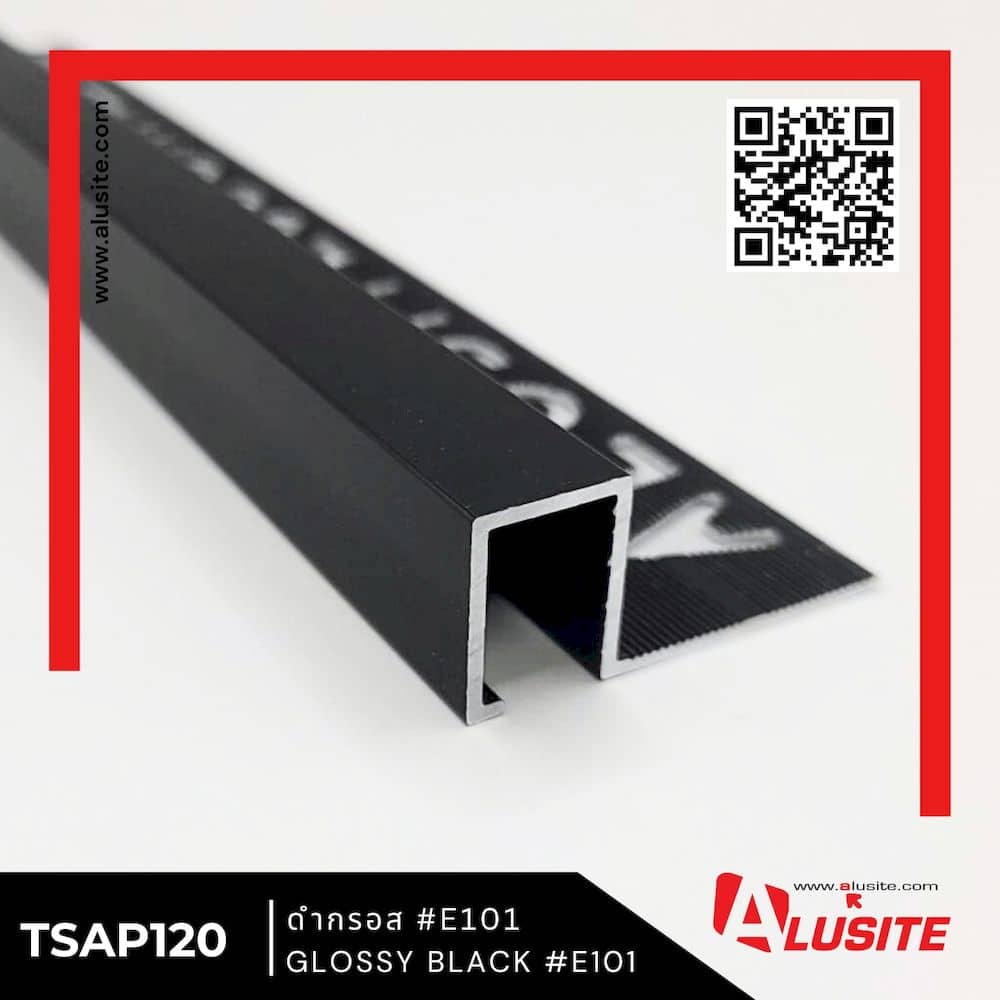

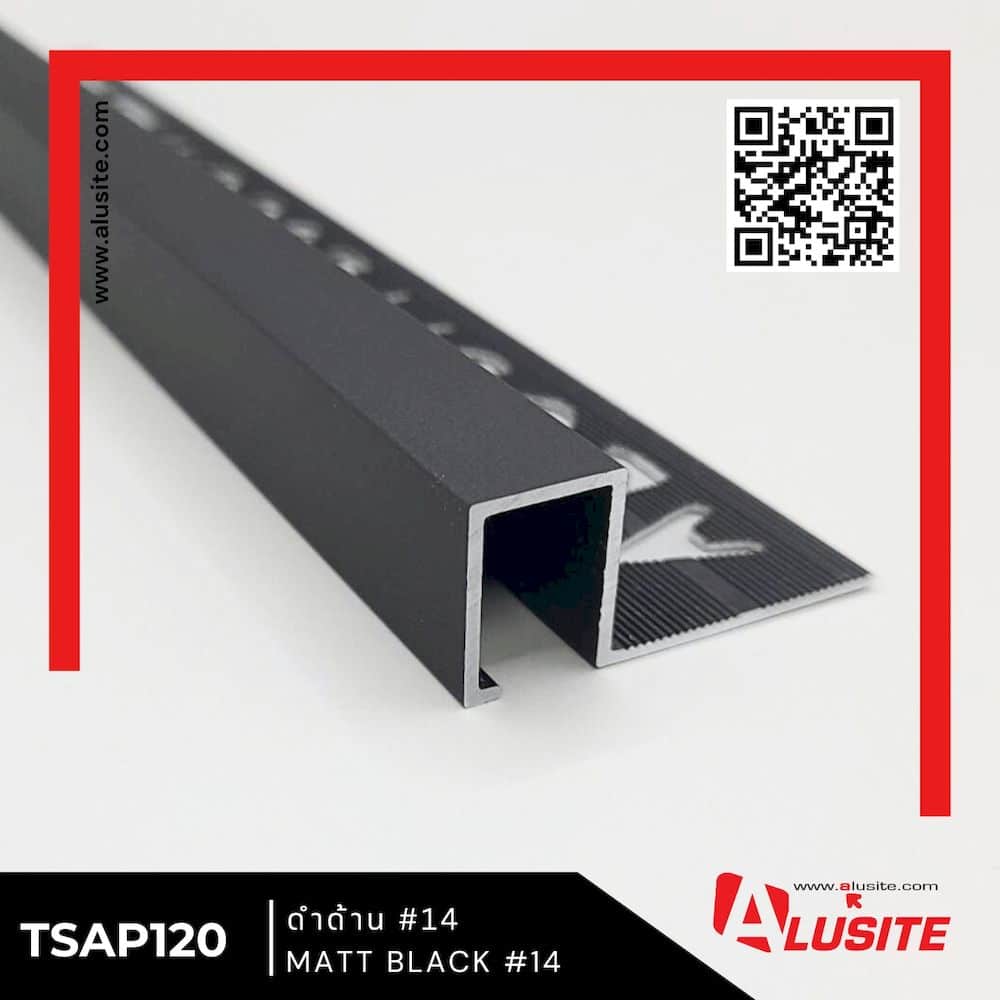

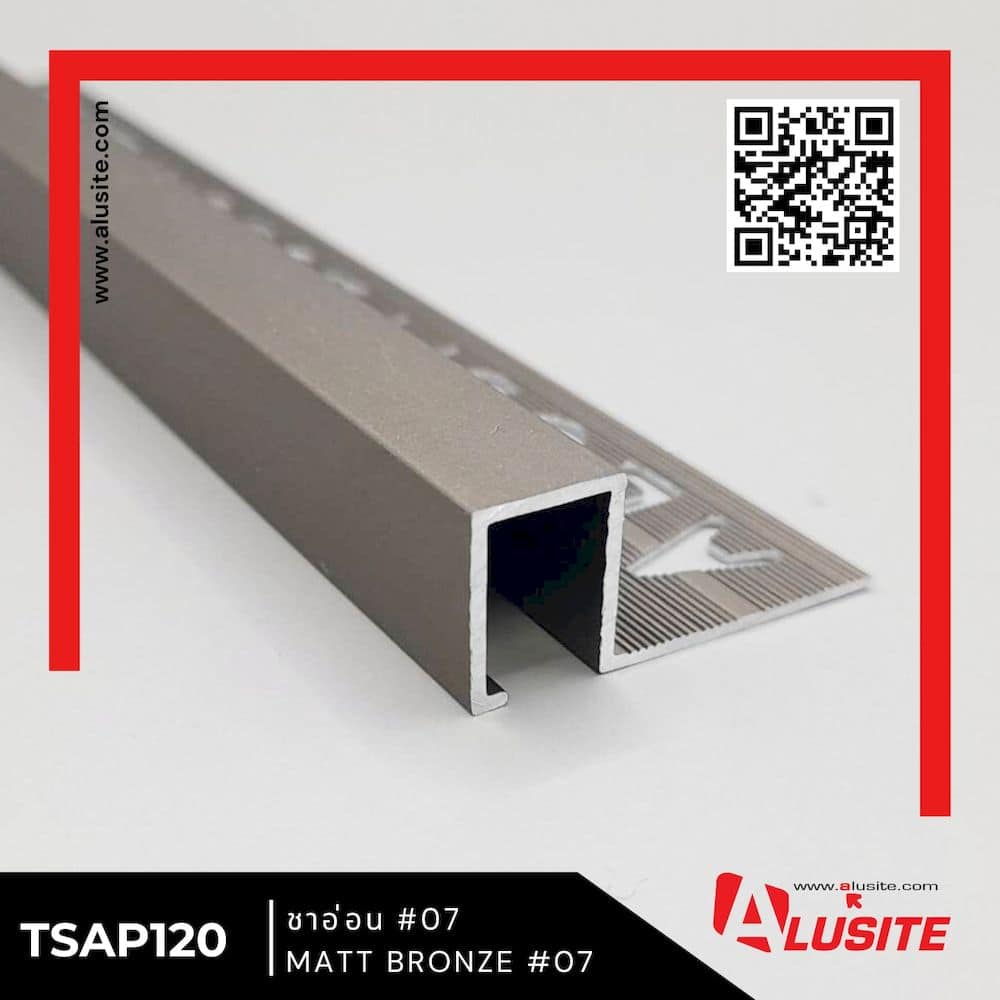

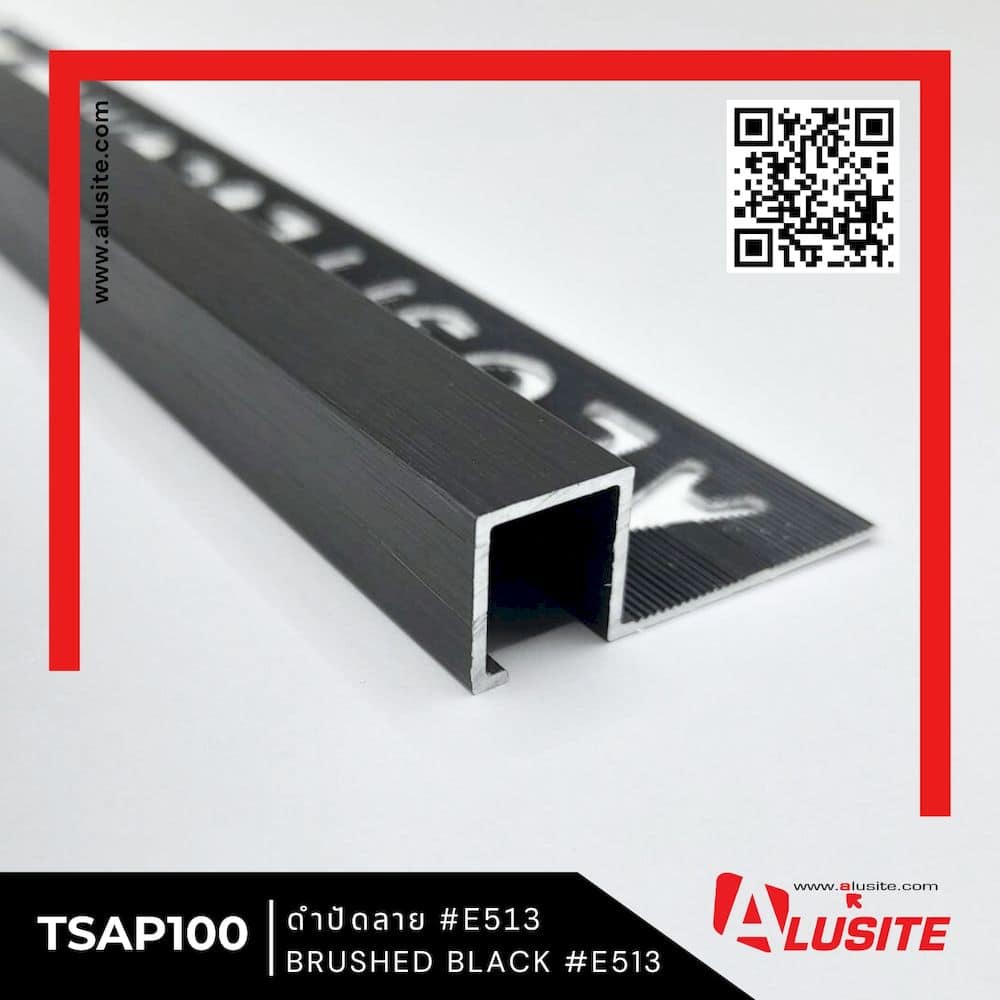

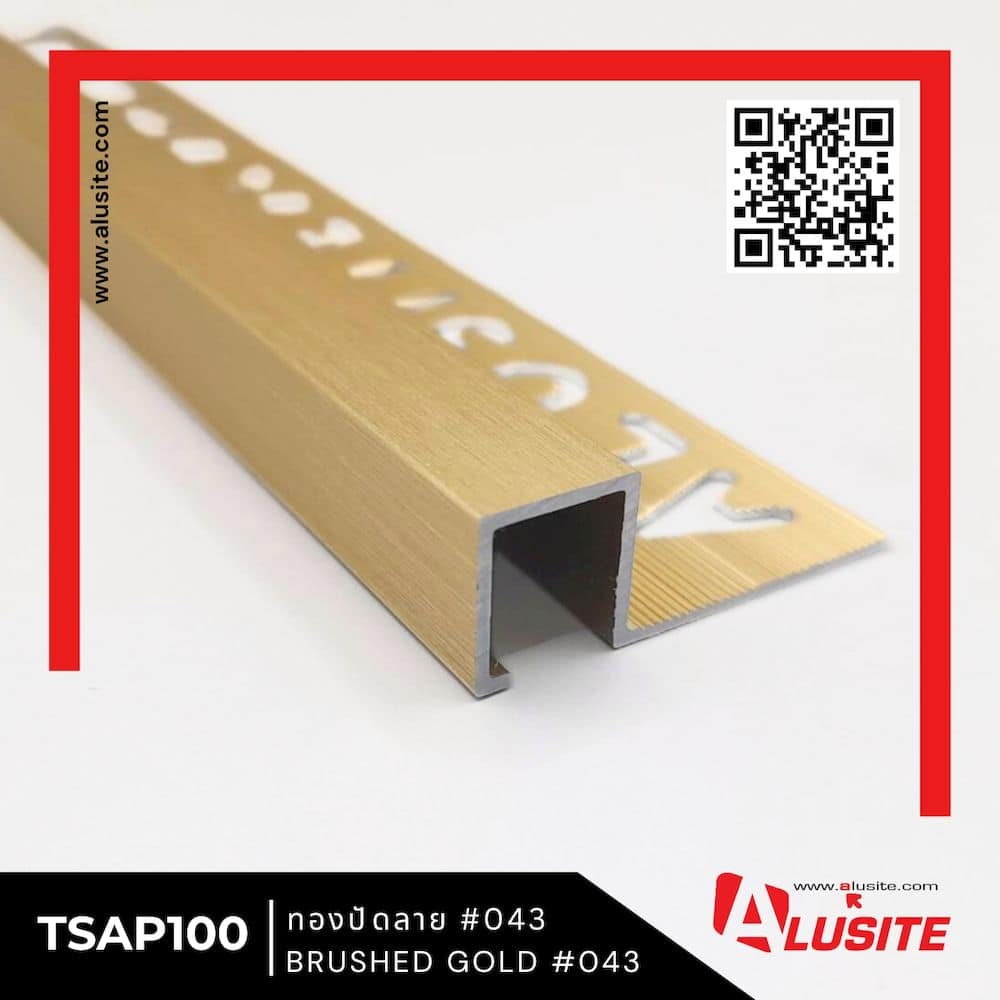

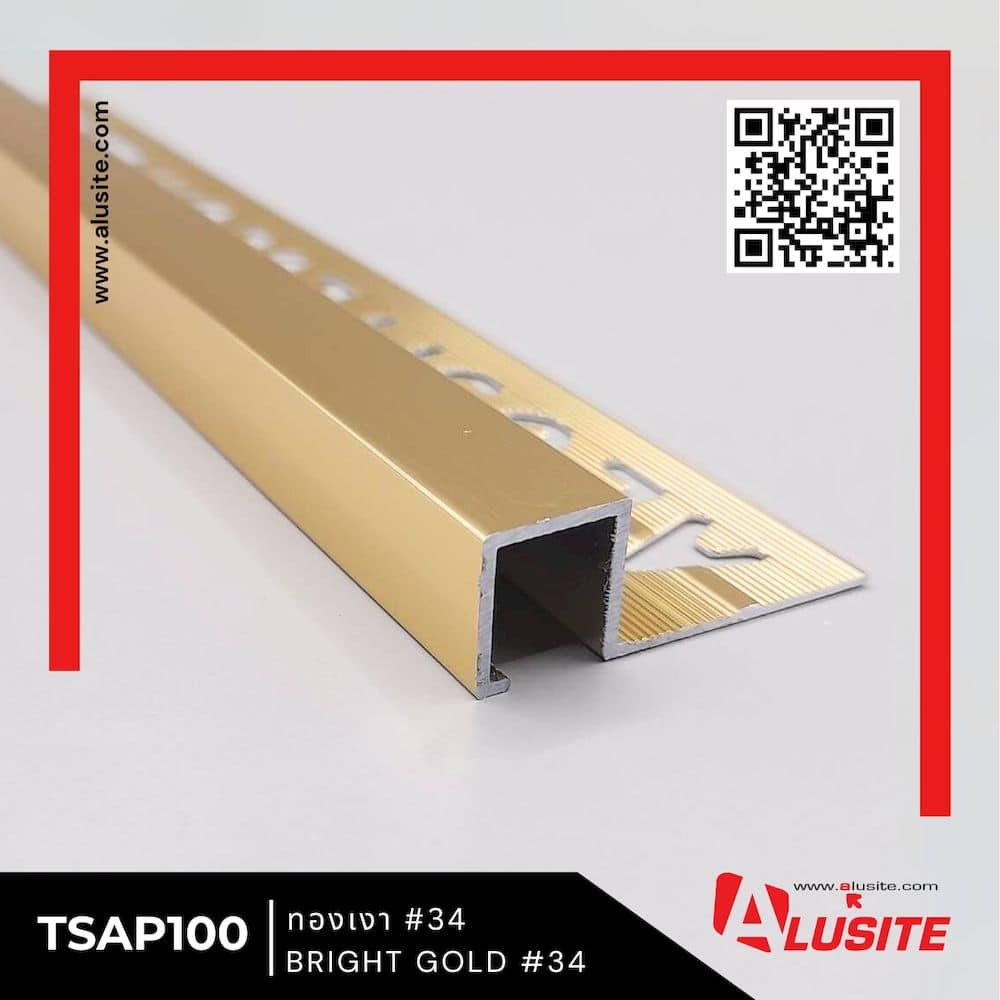

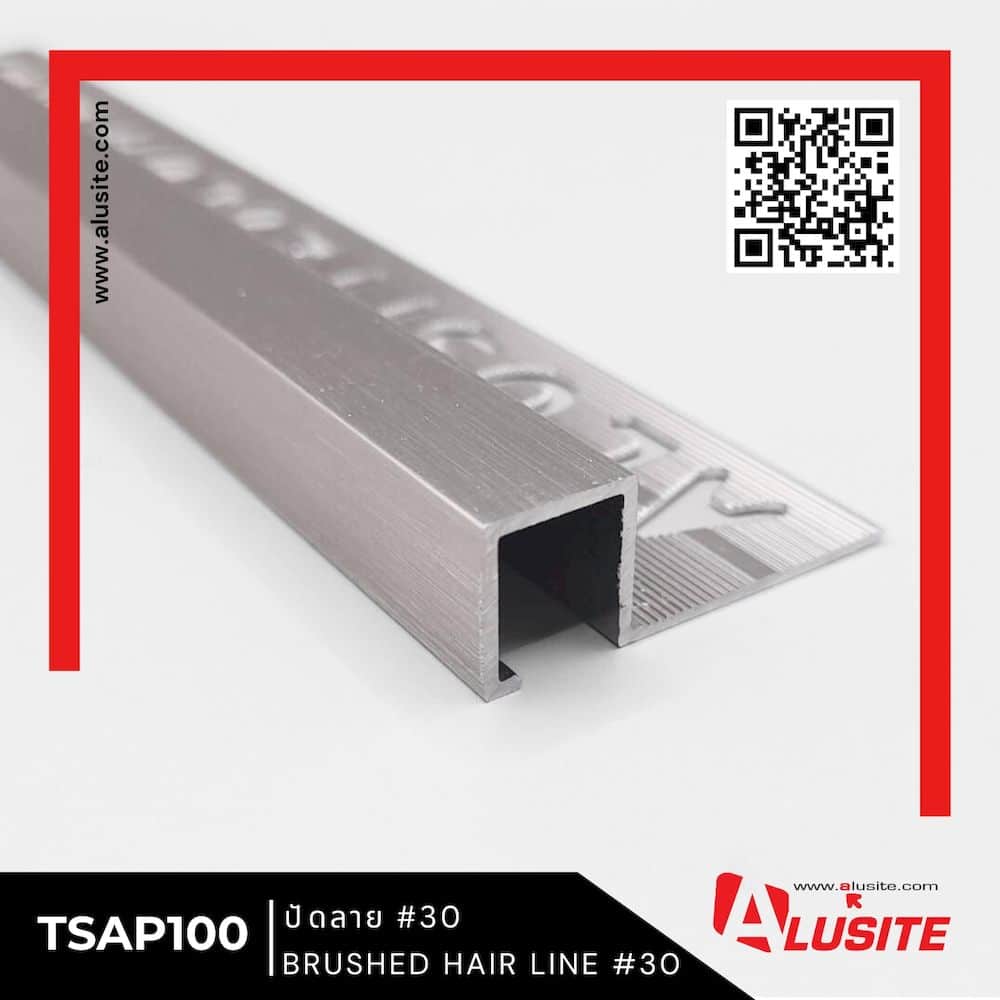

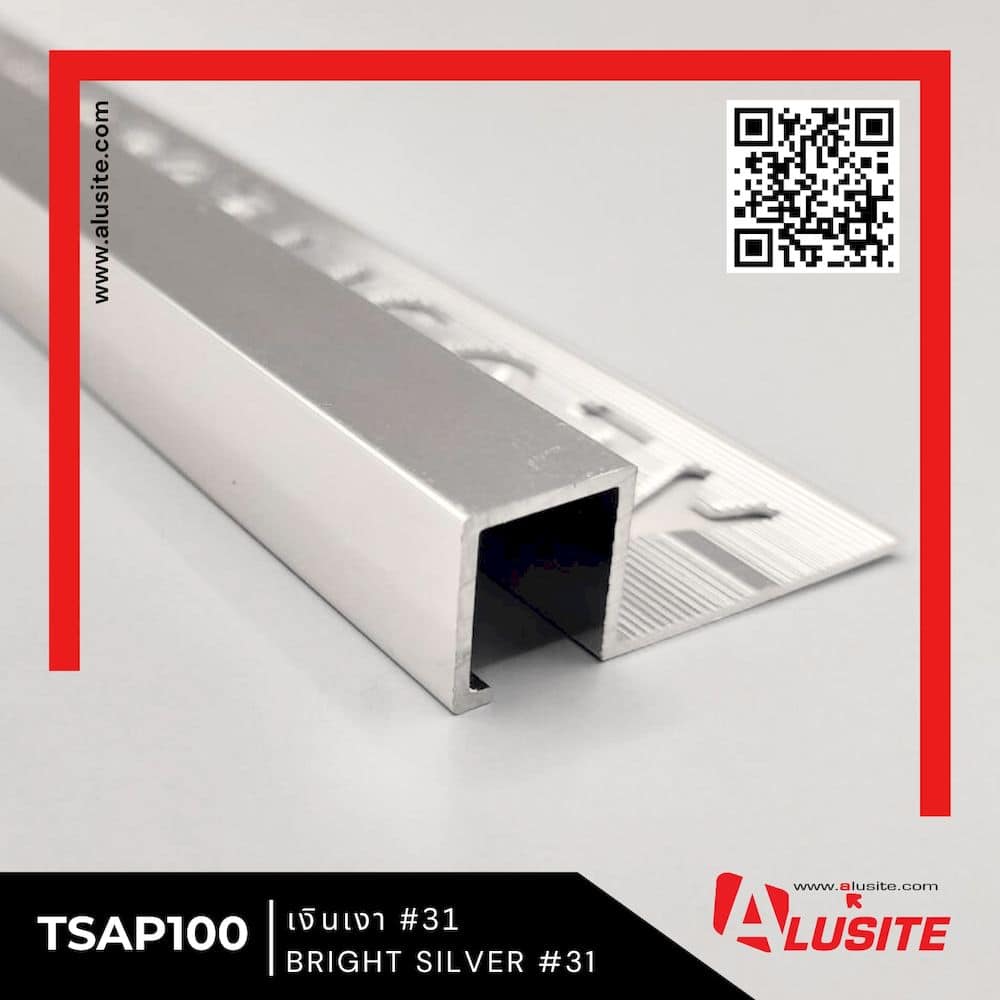

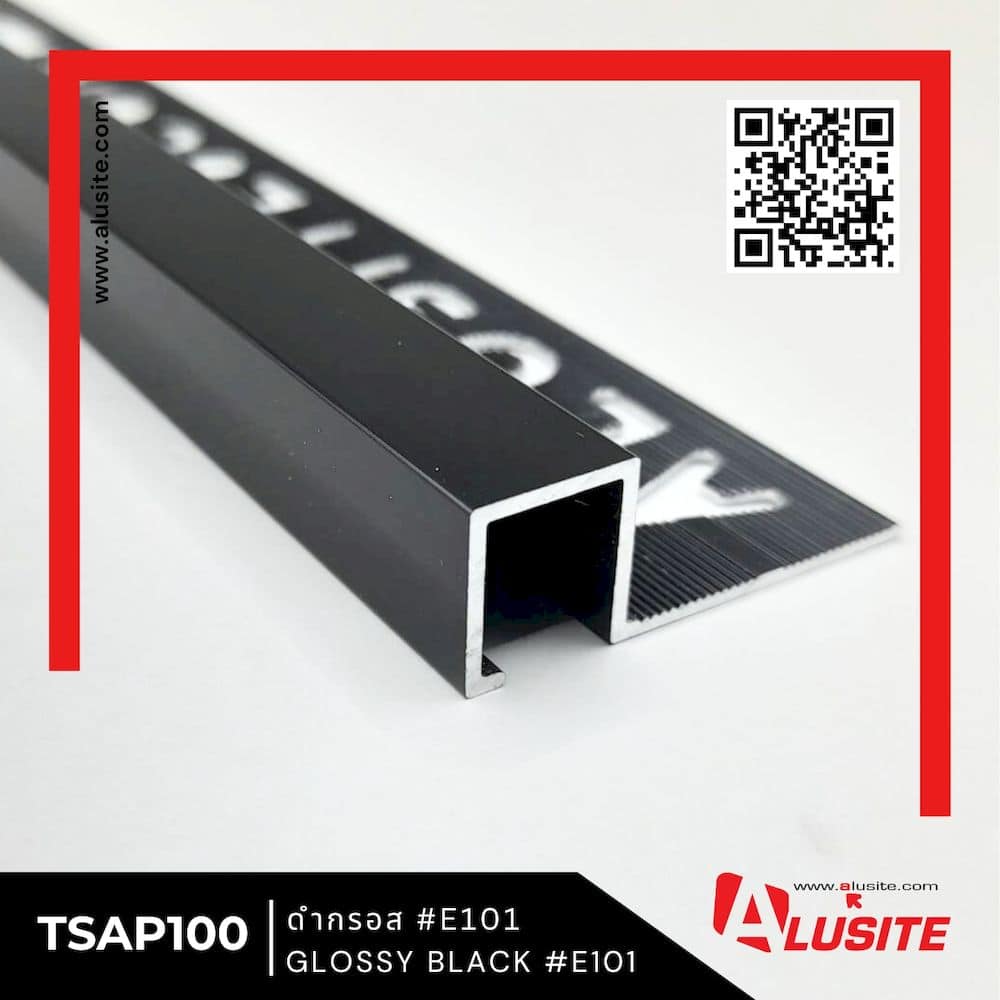

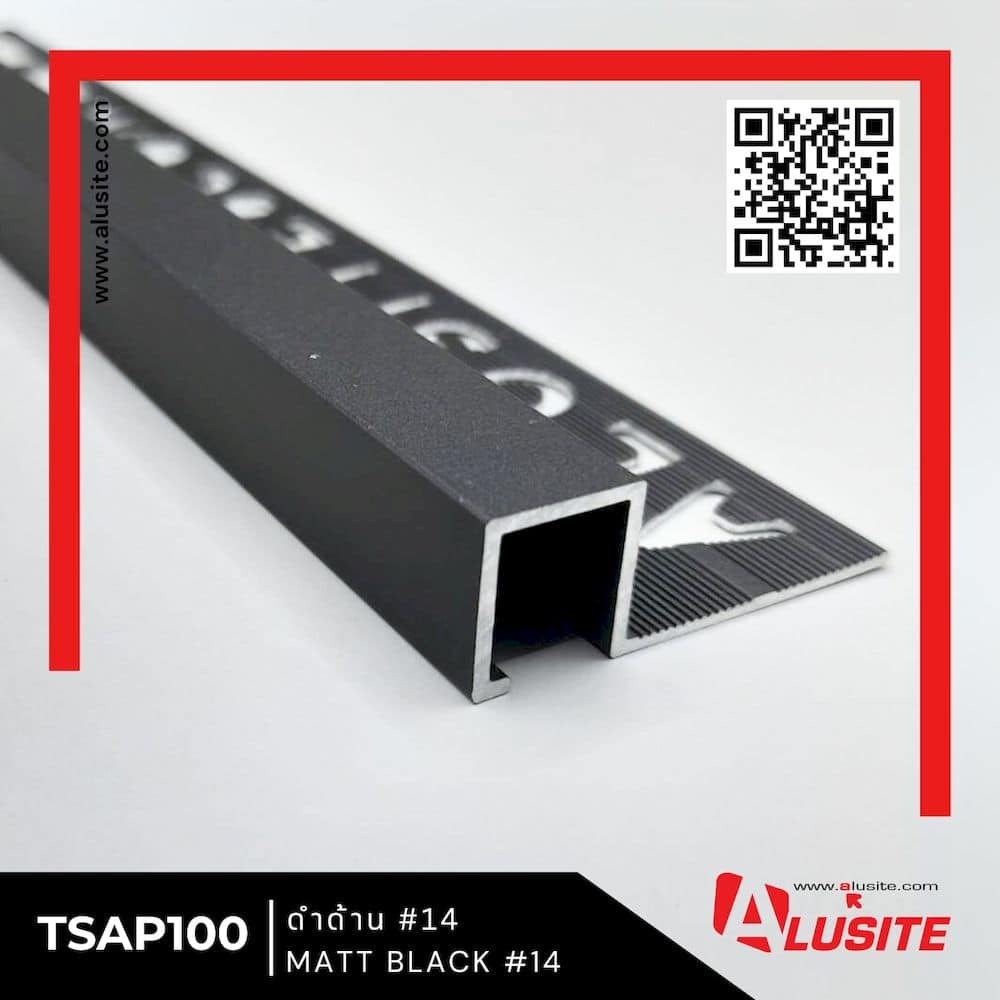

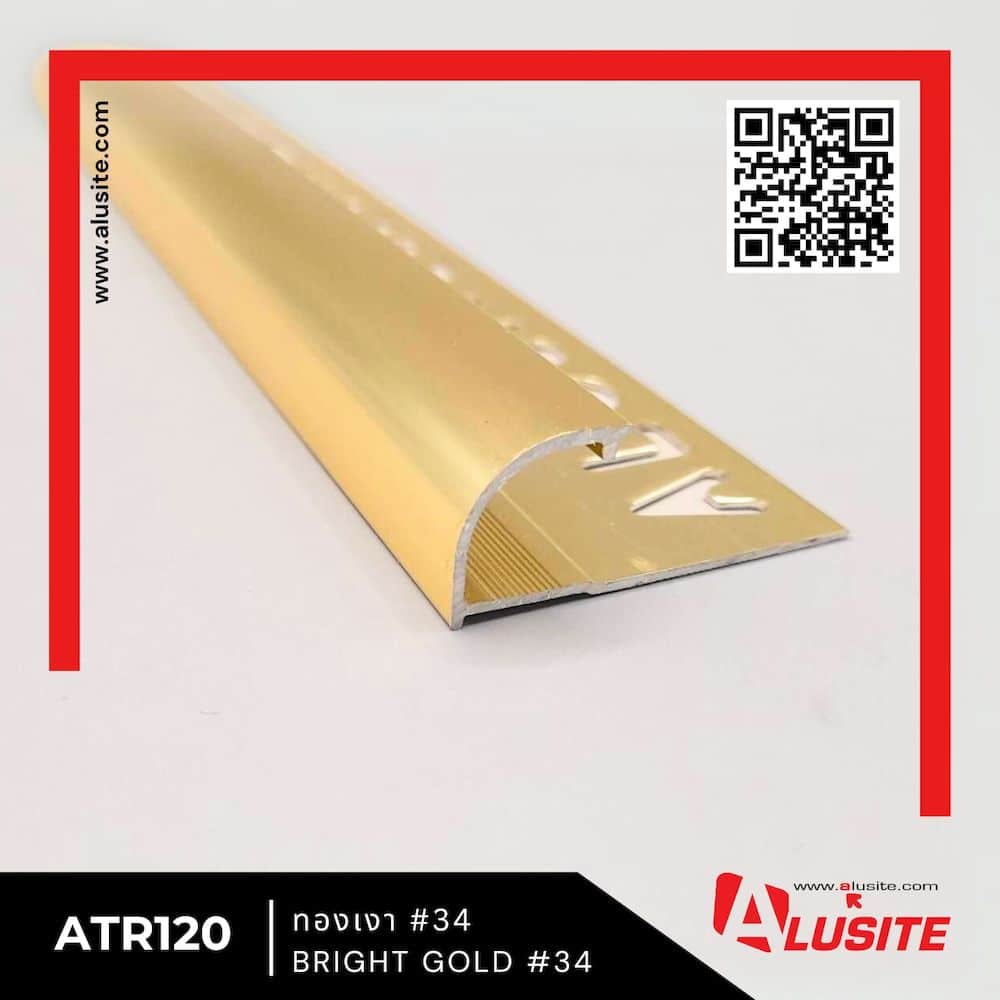

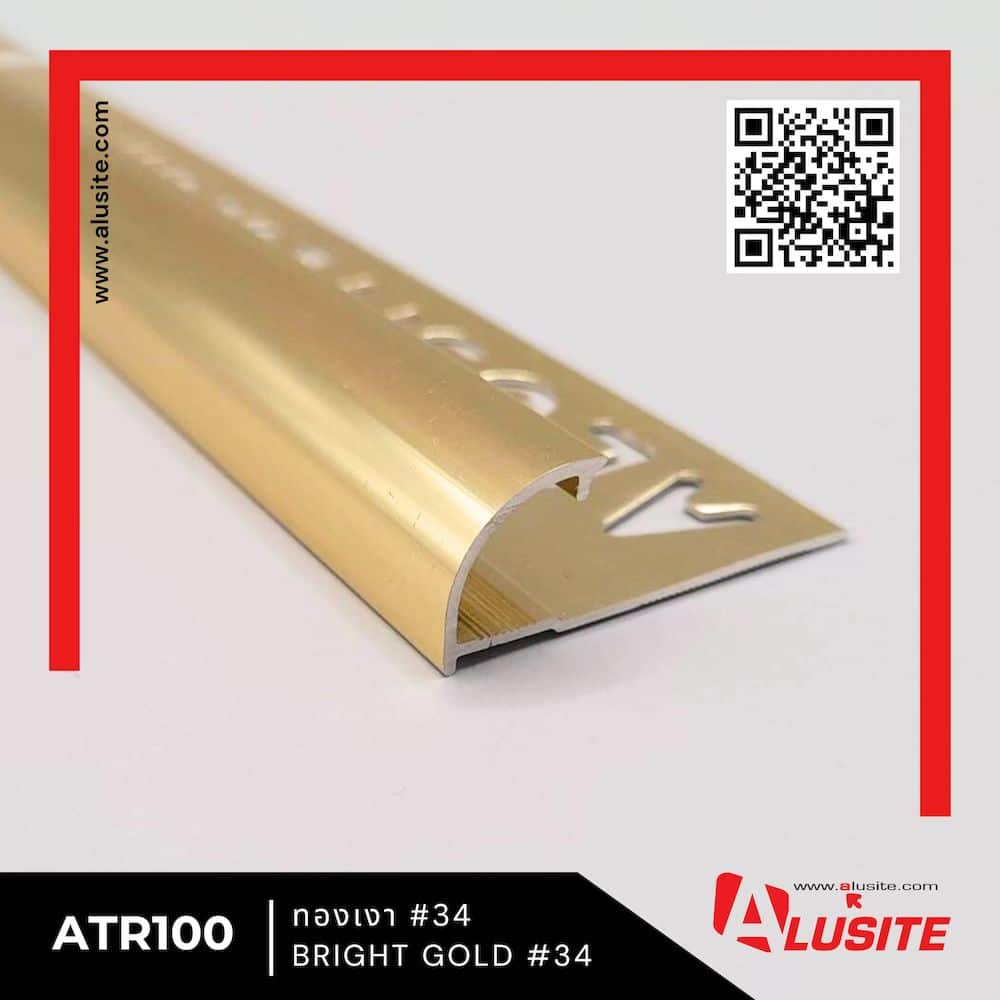

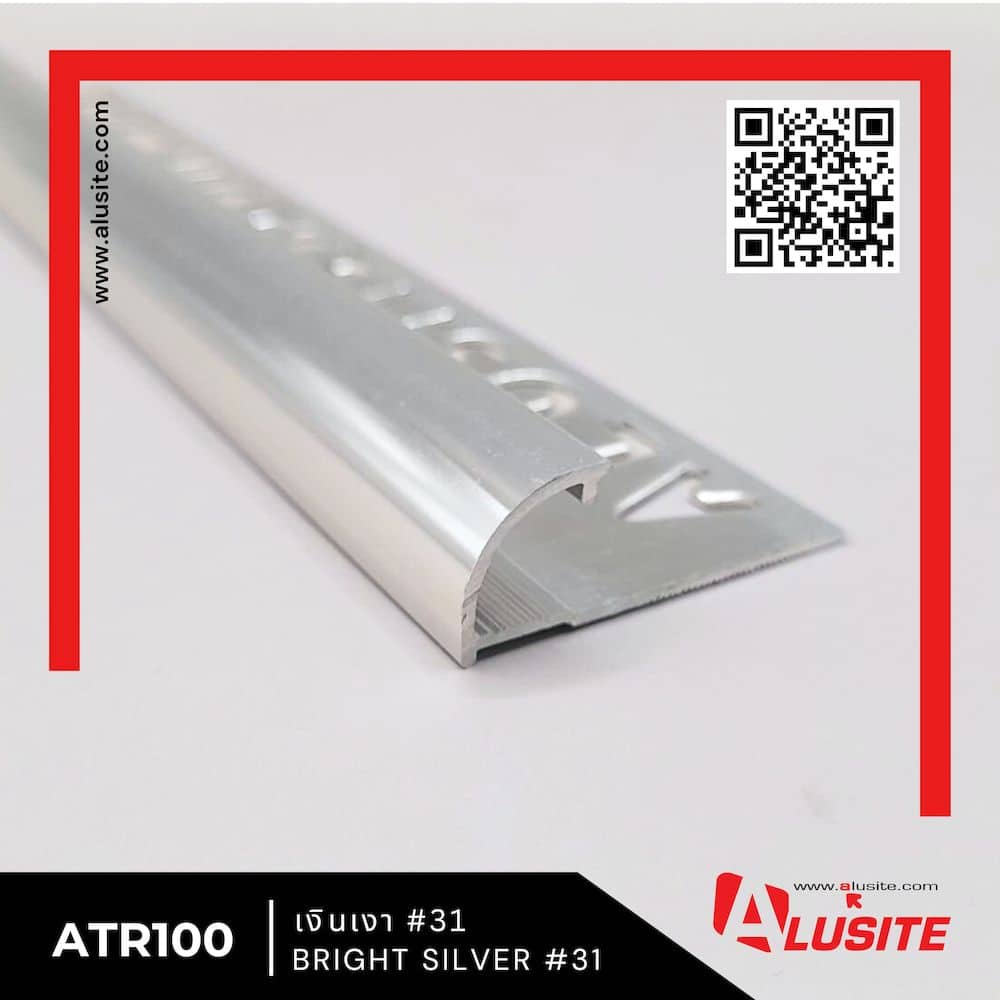

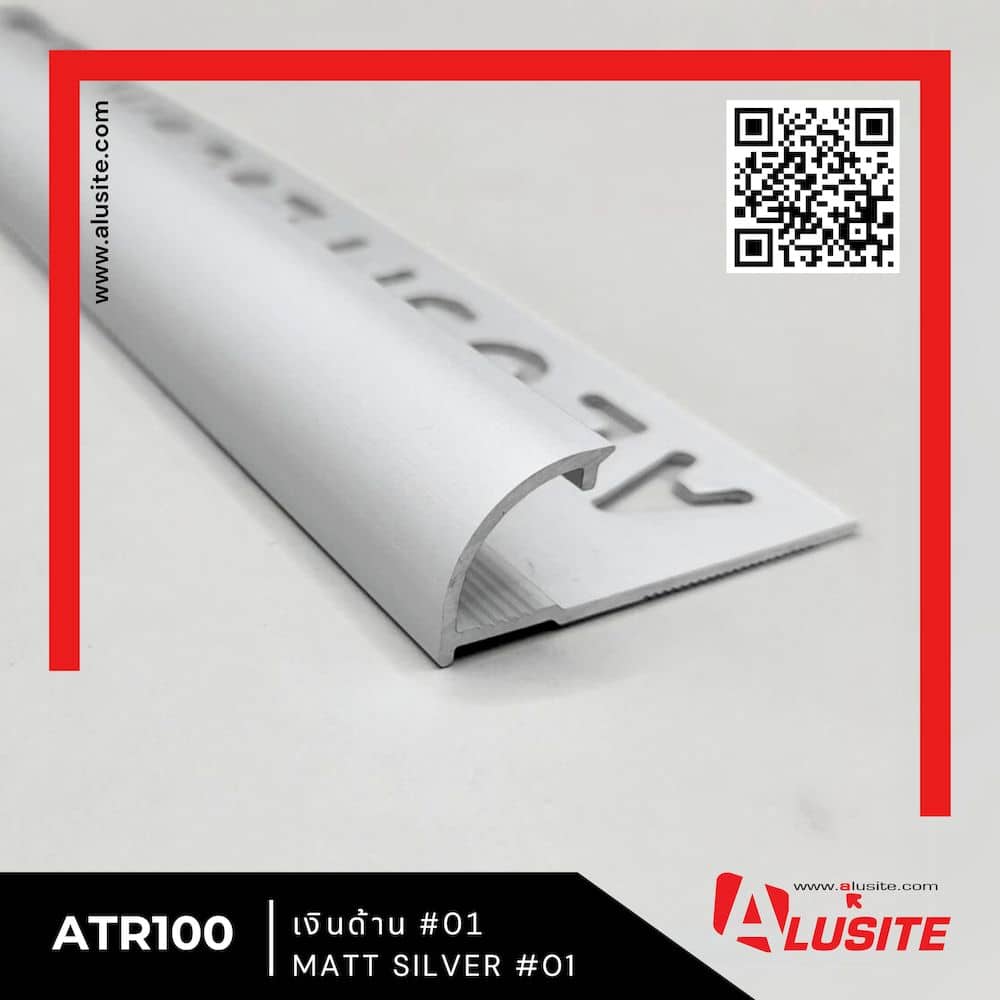

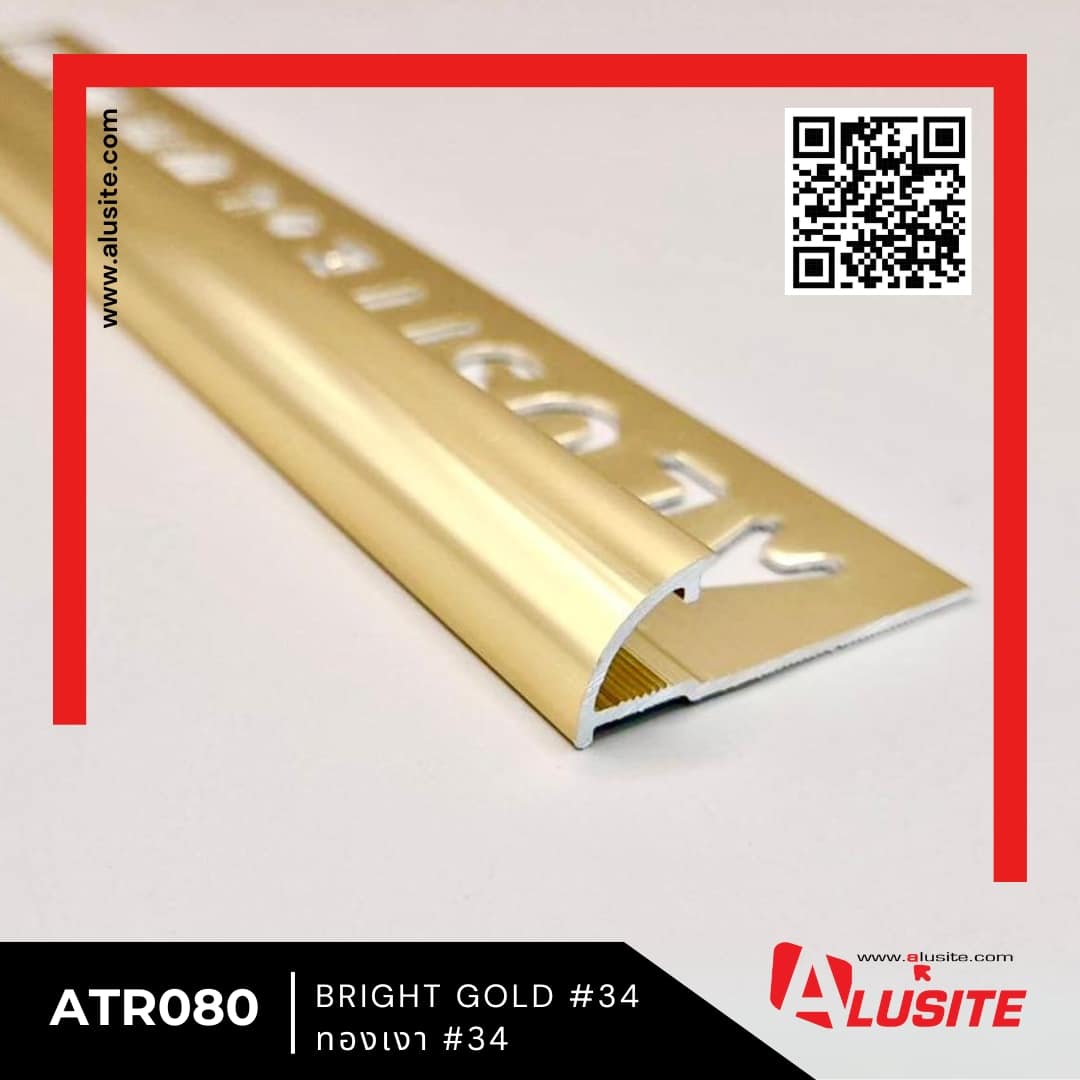

Surface finishing service, we offer a full range of surface finishings, including anodised colors, bright finishing, powder coating, laminating, hairline brushing, and hammer finishing. All our finishings are RoHS compliant.

For those who are interested in aluminum fabrication service and would like to learn more about our process, contact us for more information.